Combined type intaglio wheel rotary printing machine

A combined, printing press technology, applied in gravure rotary printing presses, rotary printing presses, printing presses, etc., can solve the problems of high ink viscosity, decreased ink transfer rate, blockage, etc., to achieve impact force and speed, ink Consistent concentration and uniform coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

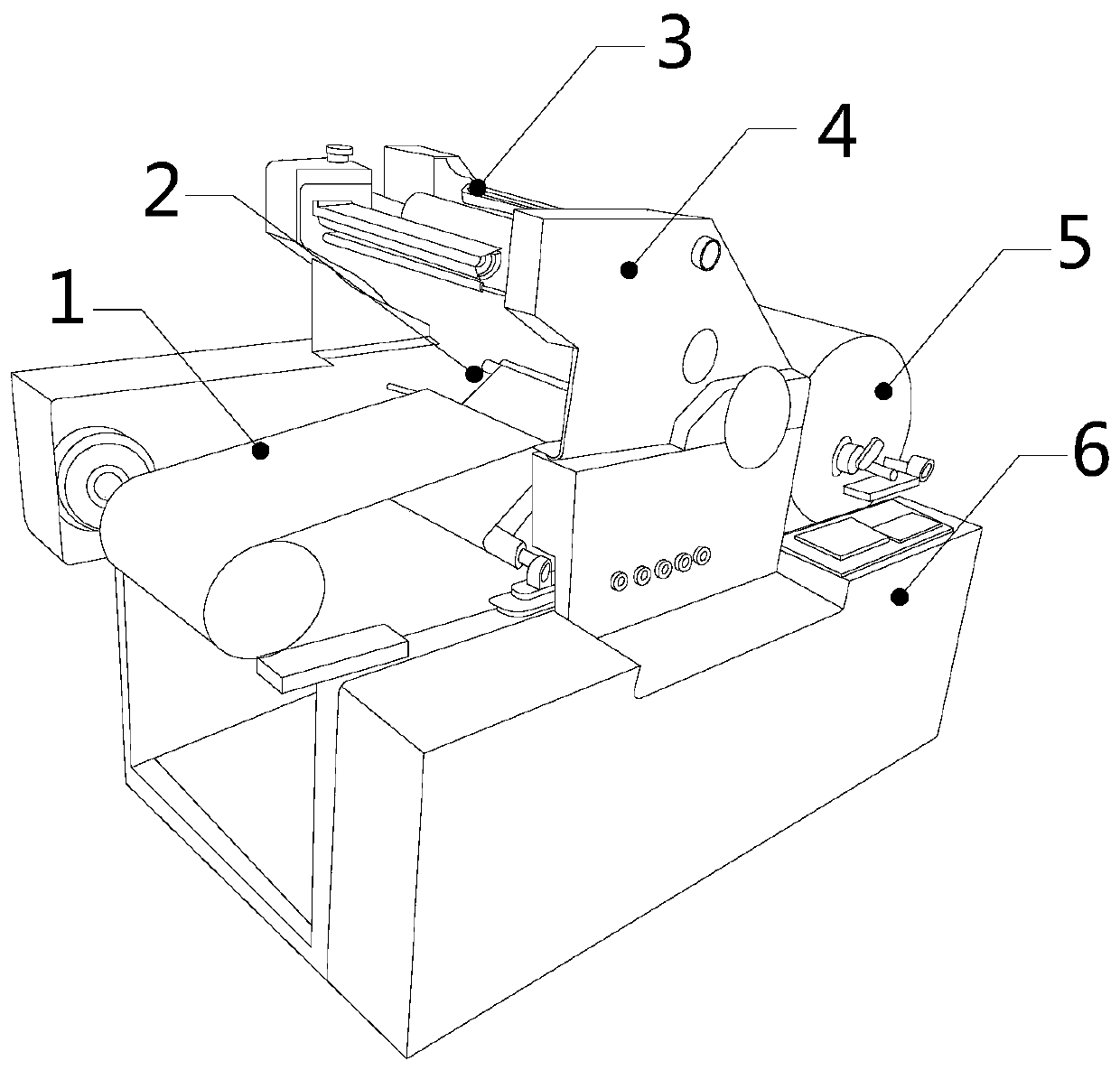

[0027] see Figure 1-Figure 6 , the present invention provides a combined gravure rotary printing machine, the structure of which includes a printing paper conveying mechanism 1, a conveying roller 2, a printing structure 3, a support seat 4, a take-up roller 5, and a body 6. The top surface of the body 6 is horizontally two A support base 4 is vertically fixed on the side, a printing structure 3 is arranged between the two support bases 4, a conveying roller 2 is installed at the bottom of the printing structure 3, and a printing paper conveying mechanism 1, A take-up roller 5, said take-up roller 5 and the printing paper conveying mechanism 1 movably cooperate.

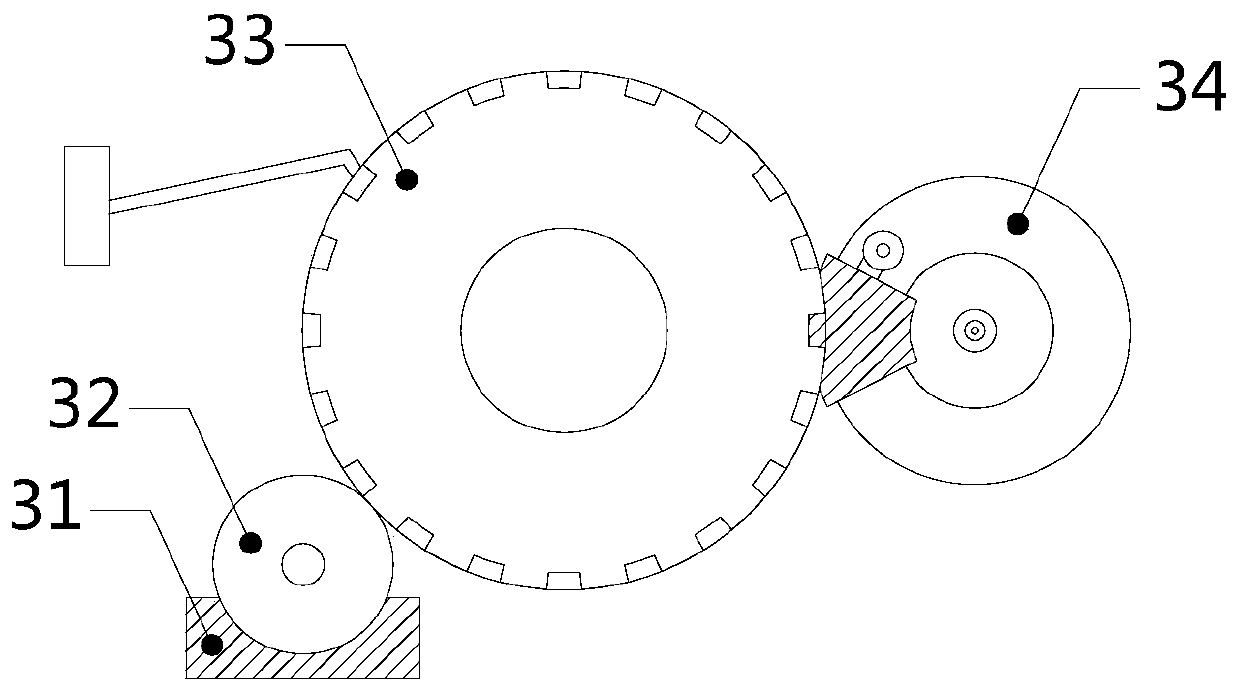

[0028] The printing structure 3 is composed of an ink tank 31, an ink transfer roller 32, a gravure cylinder 33, and a wetting cleaner 34. An ink tank 31 is installed obliquely below one side of the gravure cylinder 33, and a transmission device 31 is arranged in the ink tank 31. The ink roller 32, the ink transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com