Ultraviolet-proof energy-saving heat-insulating tempered glass

A tempered glass and anti-ultraviolet technology, which is applied in glass tempering, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of easy damage of glass, uneven stress distribution, etc., and achieve performance improvement, uniform stress, and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

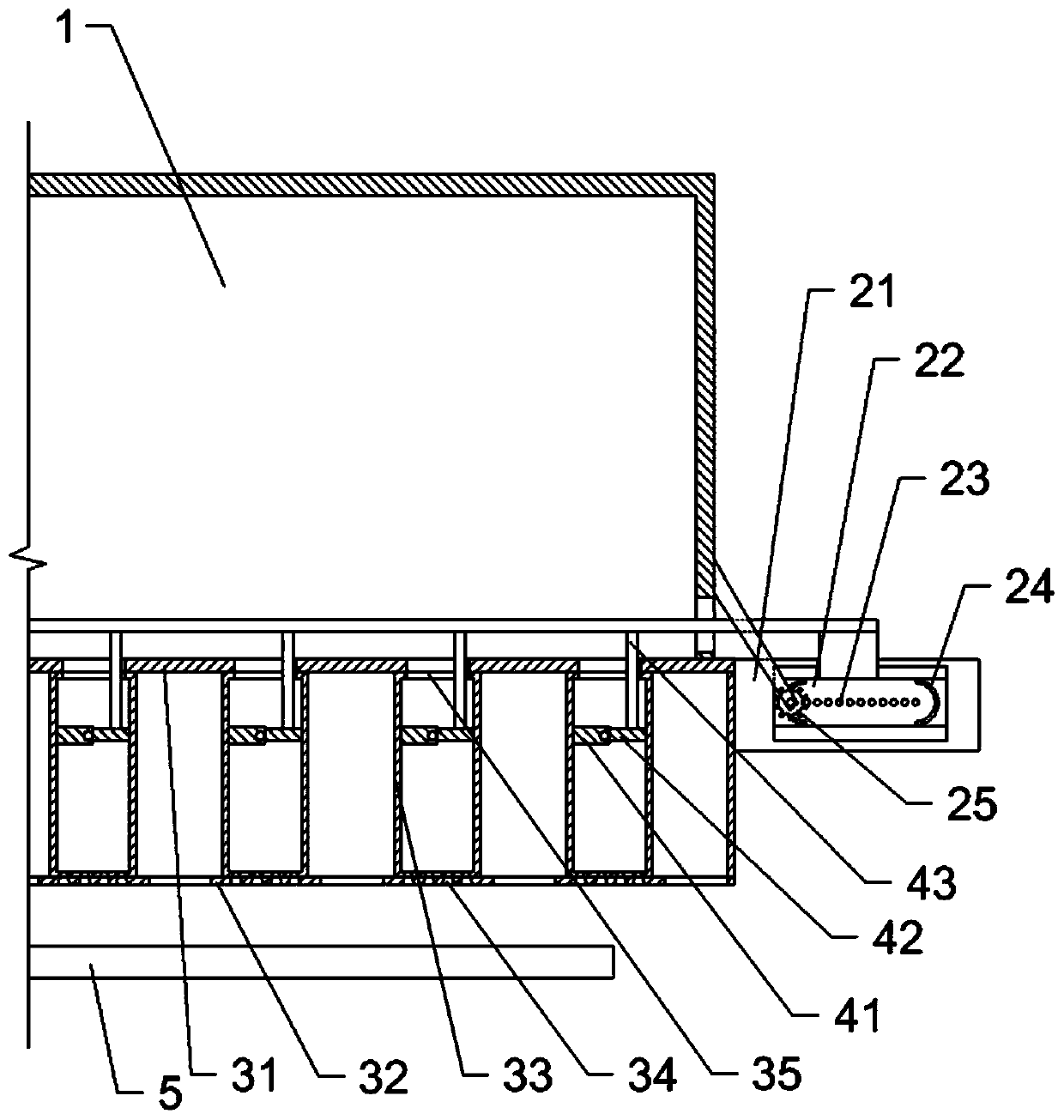

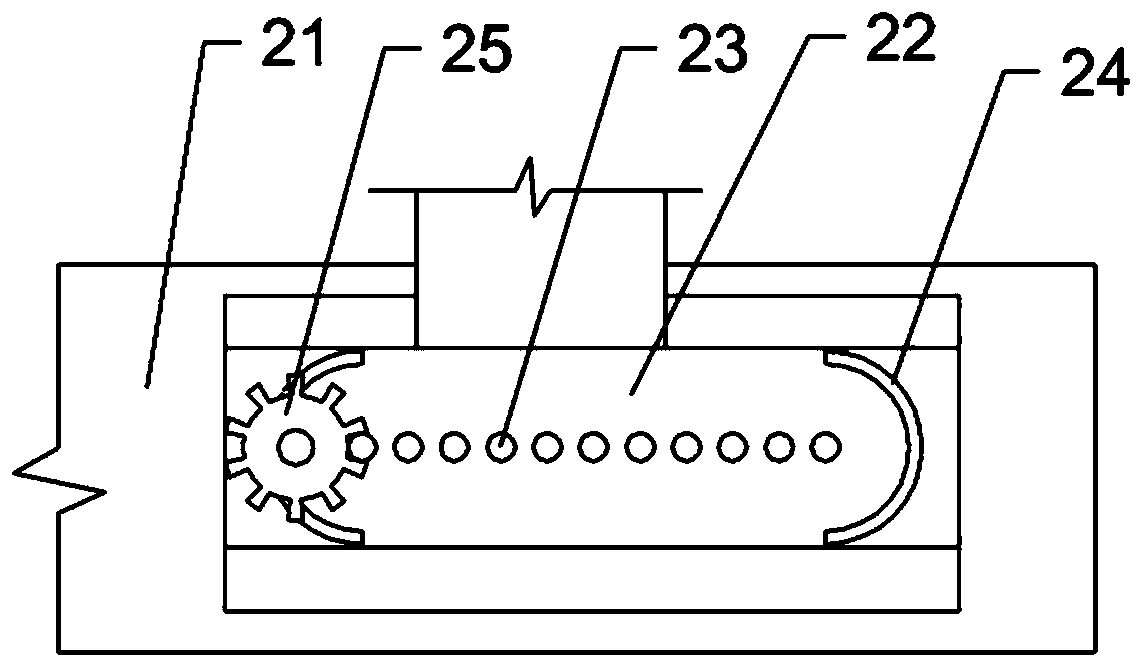

[0021] The reference signs in the accompanying drawings of the description include: bellows 1, slider 21, moving block 22, cylindrical rod 23, limit block 24, gear 25, upper clamping plate 31, lower clamping plate 32, wind strip 33, air jet Port 34, air inlet 35, fixed valve plate 41, moving valve plate 42, pull rod 43, glass sheet 5.

[0022] The embodiment is basically as attached figure 1 Shown: Anti-ultraviolet, energy-saving and heat-insulating tempered glass, which is made by the following method, which specifically includes the following steps:

[0023] Slicing step: use the existing glass cutting machine glass original sheet to cut to make the glass sheet 5 whose size meets the requirements;

[0024] Grinding step: use the existing glass grinding machine to grind the cut glass sheet 5 to improve the smoothness of the glass;

[0025] Cleaning step: use the existing glass cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com