Drying kiln detecting door safety lock

A technology for detecting doors and safety locks, which is applied in the field of safety locks, can solve problems such as safety risks and lack of two-way opening function, and achieve the effect of prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

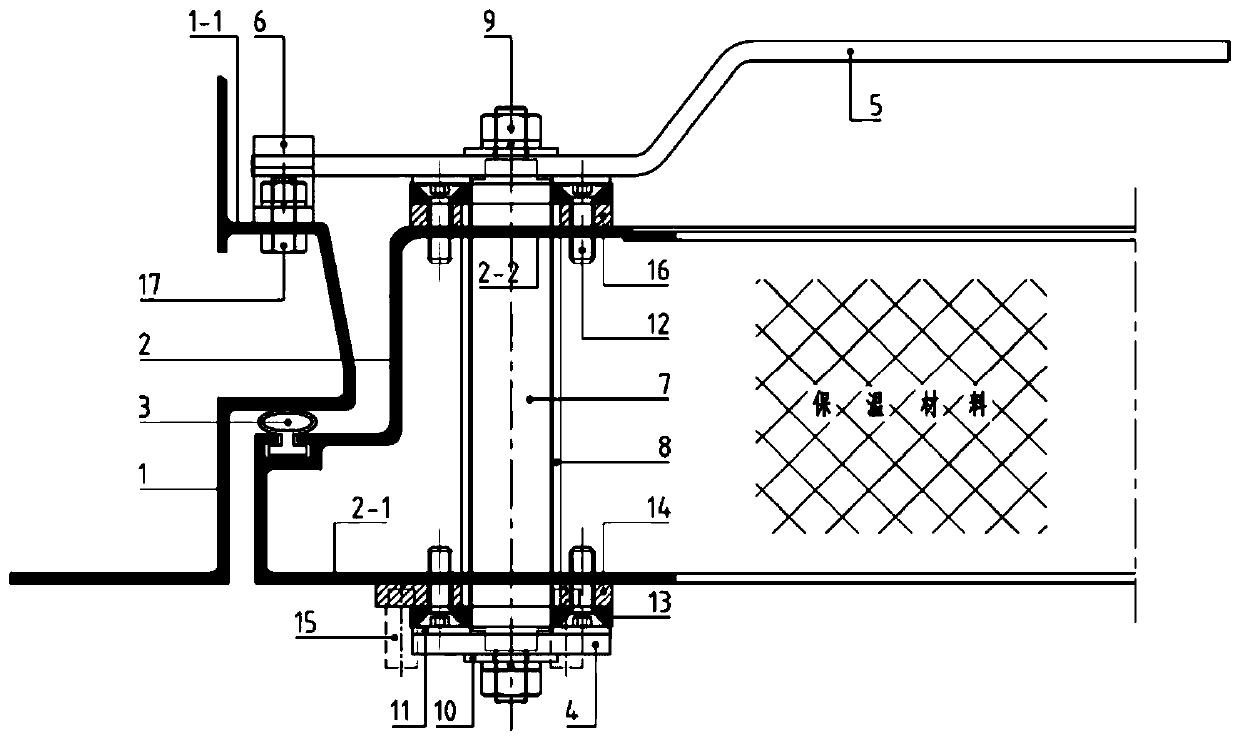

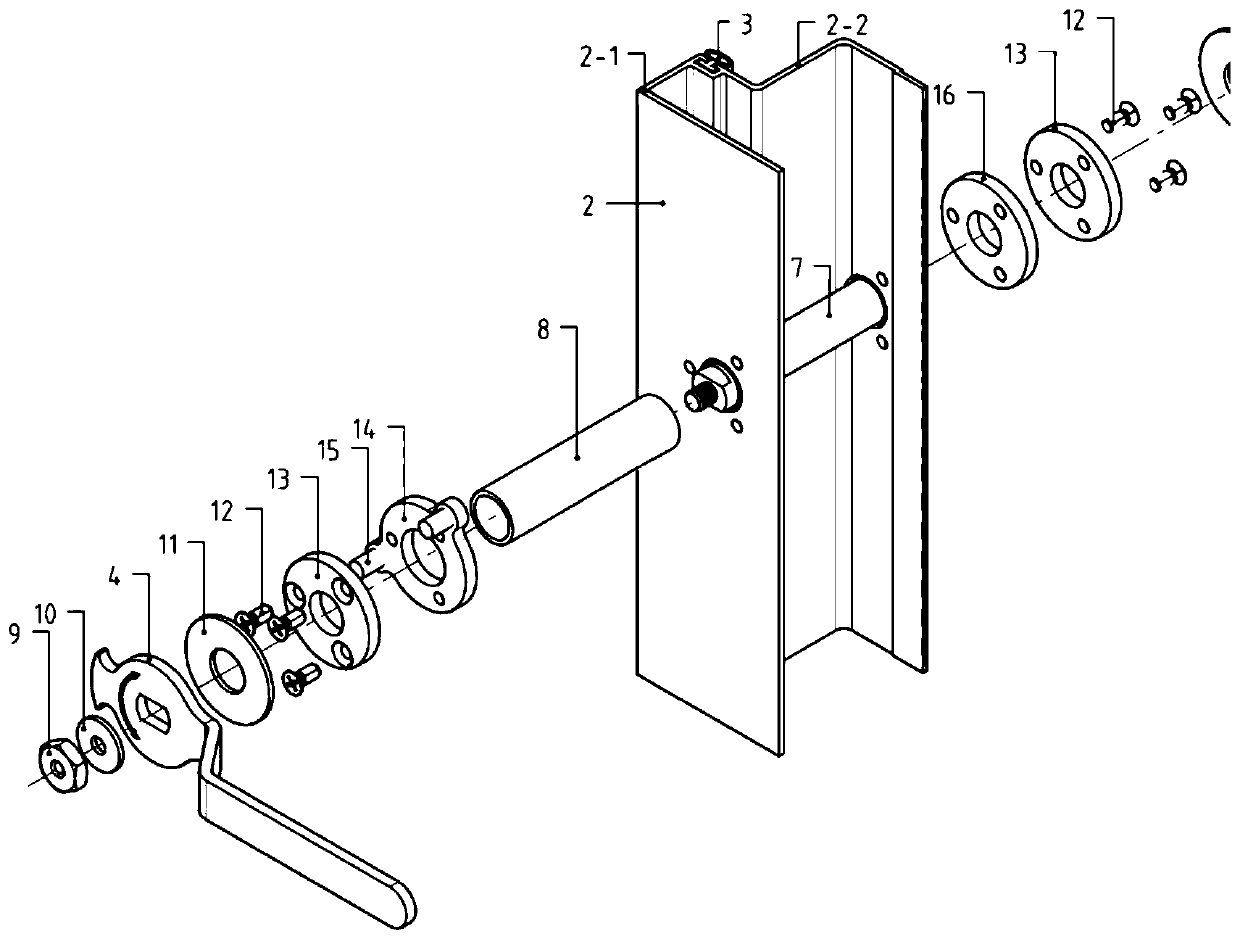

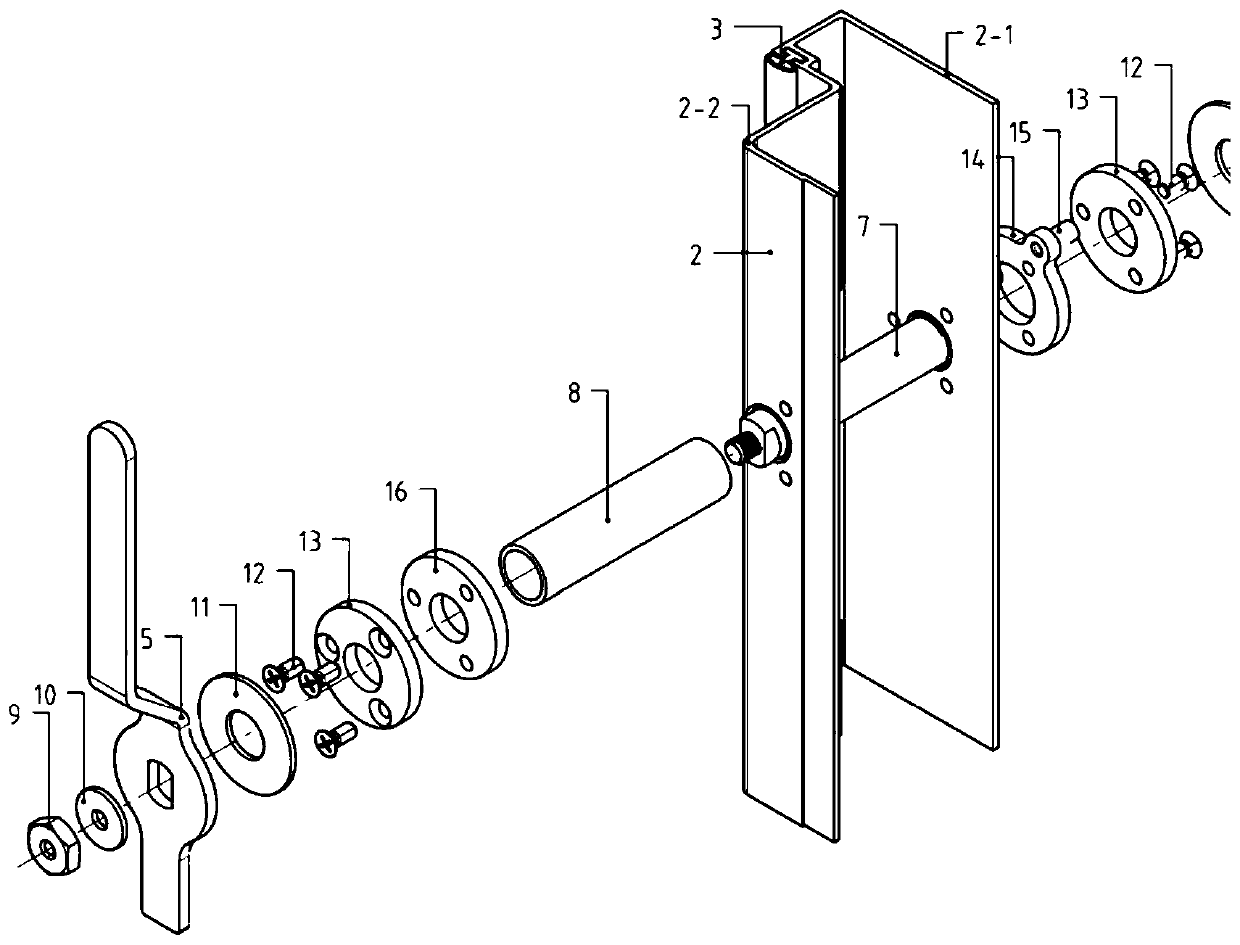

[0036] Drying kiln detection door safety lock, including outer handle 4, inner handle 5, locking point 6, drive shaft 7, bushing 8, M8 self-locking nut 9, Φ23 flat washer 10, Φ50 flat washer 11, countersunk head bolt 12, fluorine Rubber sealing gasket 13, outer flange 14, inner flange 16, bolt 17; drive shaft 7 runs through the inner circle of shaft sleeve 8, and shaft sleeve 8 passes through outer wall 2-1 and inner wall 2-2 of detection door frame 2, The two ends of the shaft sleeve 8 are respectively welded with the outer flange 14 and the inner flange 16 and pressed and sealed with the outer wall 2-1 and the inner wall 2-2; , the countersunk head bolt 12 fastens the fluororubber sealing washer 13 and the outer flange 14 on the outer wall 2-1 of the detection door frame, and the countersunk bolt 12 fastens the fluororubber sealing washer 13 and the inner flange 16 together On the inner wall 2-2 of the detection door frame; Φ50 flat pads 11 are inlaid on both ends of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com