A Mechanical Disturbance Throat Deviation Type Pneumatic Vectoring Nozzle

A technology of vectoring nozzle and throat, applied in the field of advanced thrust vectoring nozzle, can solve the problem of large thrust loss, achieve the effect of reducing weight, shortening length and diameter, and simplifying nozzle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

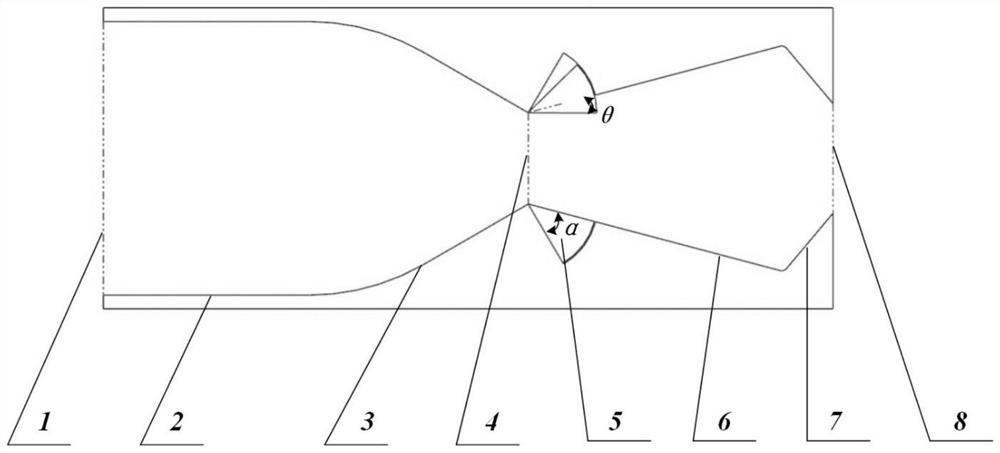

[0052] Calculations are performed for a mechanically perturbed throat-offset aerodynamic vectoring nozzle in a typical binary configuration.

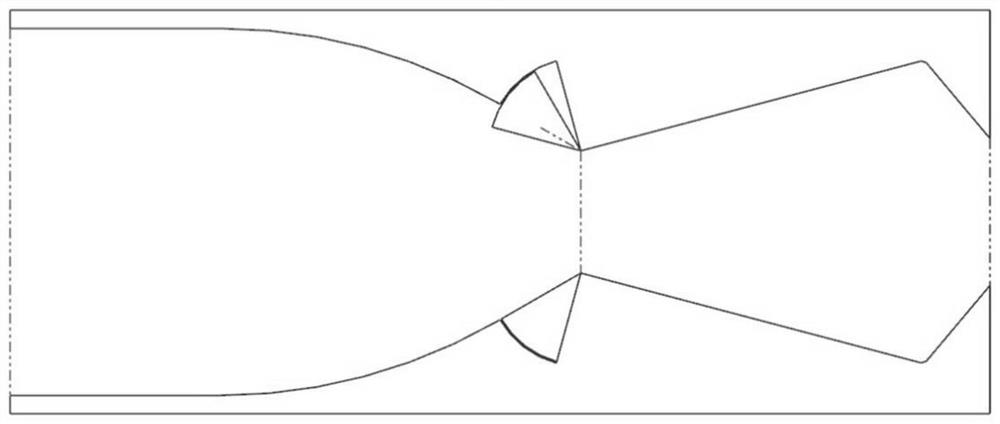

[0053] Figure 5 , 6 Shown is the numerical calculation Mach number cloud chart of NPR=2 and NPR=3 when the mechanical disturbance vane method with the rotating shaft in front of a throat sharp point and the mechanical disturbance vane is rotated out by 25%. It can be seen that, at the same degree of unscrewing, the thrust vector angle of the nozzle's working pressure ratio NPR = 2 is inclined upwards, and at this time it is the head-up vector; and when the working pressure ratio is increased to NPR = 3, the vector angle is obviously downward Oblique, the bow vector appears. This is detrimental to the aircraft control system due to the premature attachment of the airflow to the mechanical spoiler, so work at NPR ≤ 2 should be avoided for this regulation scheme.

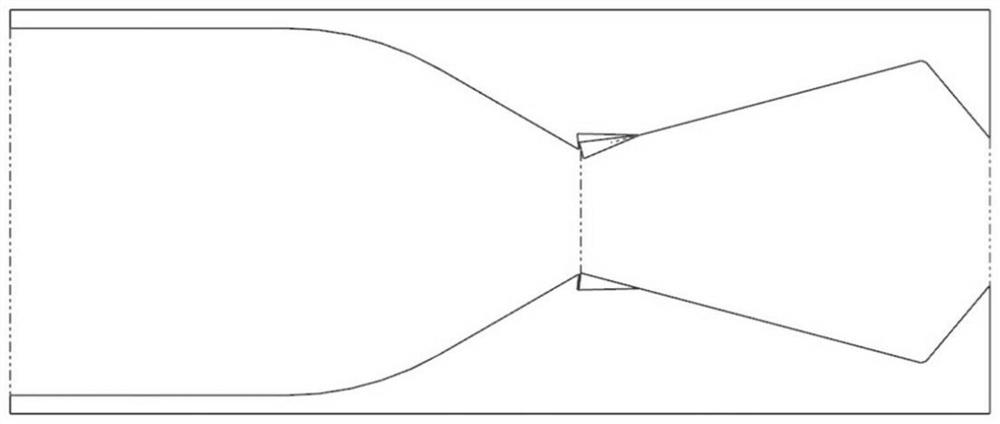

[0054] Figure 7 Shown is the Mach number cloud diagram calculated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com