Spliced ring gear track and its horizontality and coaxiality pose decoupling adjustment method

A levelness and track technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of high processing difficulty, high cost, slow installation speed, etc., to overcome the difficulty of processing, high positioning accuracy, fast The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

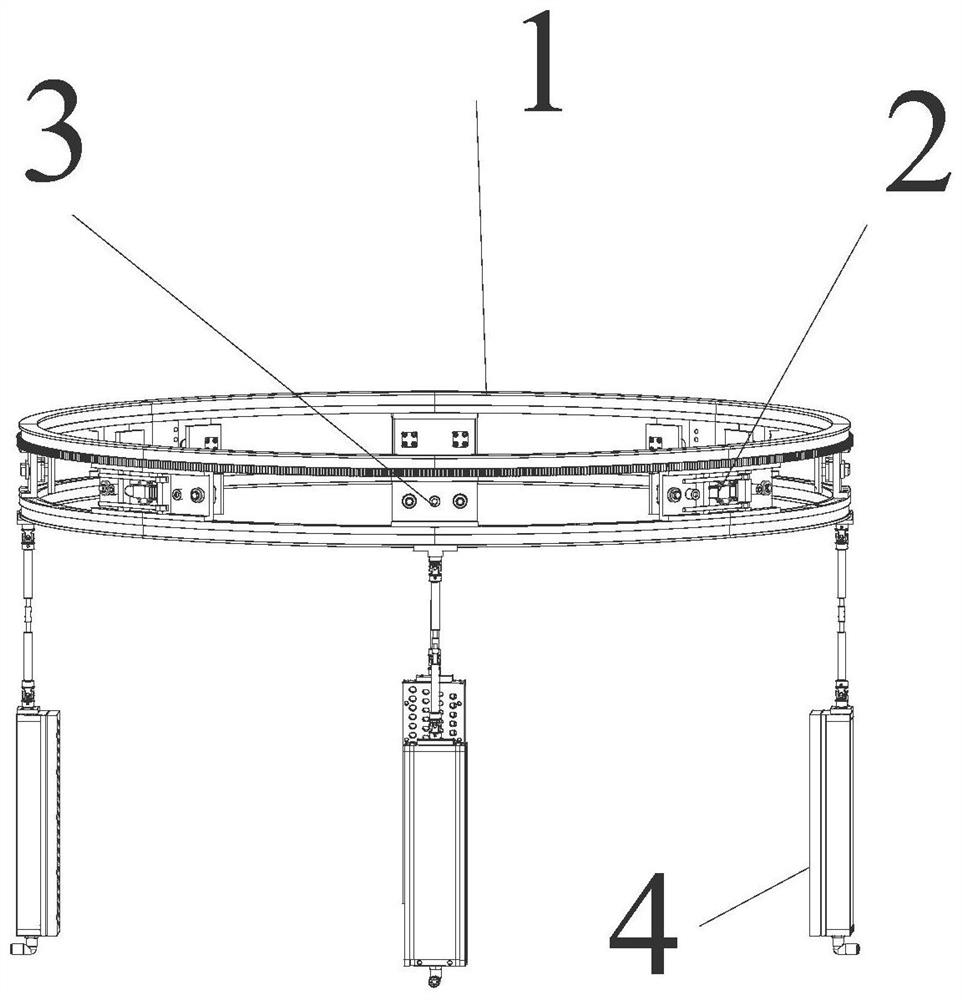

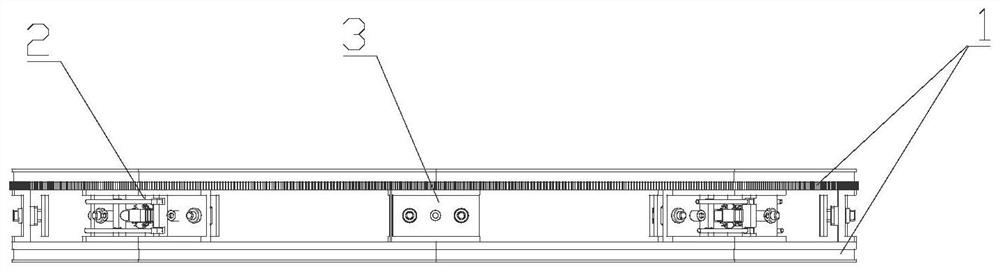

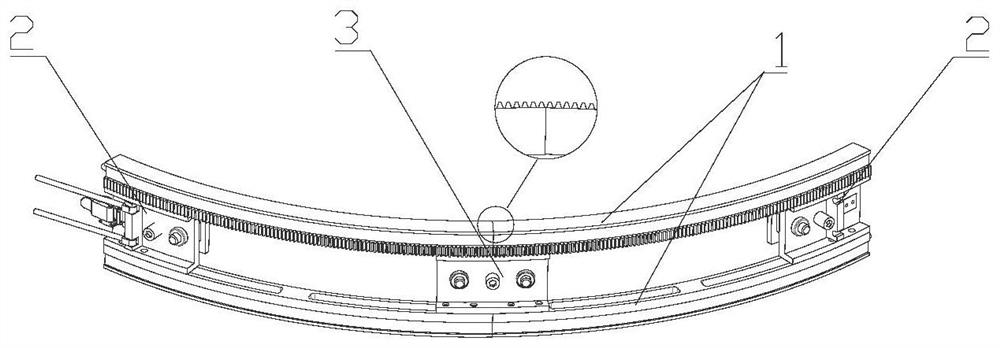

[0085] A spliced ring gear track, such as figure 1 shown, including four segments identical to the image 3 In the segmented track 1 shown, the four segmented tracks are spliced end to end to form a circle such as figure 2 The splicing diagram of the track of the ring gear shown is as follows Figure 4 As shown in , a levelness and posture adjustment device is installed under the ring gear track;

[0086] Segmented track 1 includes an upper track and a lower track parallel to each other. The outer edge of the upper track is provided with a ring gear. The detection travel mechanism is meshed with the ring gear through the gear, and then the detection travel mechanism is driven to realize the entire circumference of the ring gear track. The upper and lower tracks share 8 sections, one segmented track 1 is spliced by an upper track and a lower track;

[0087] Among them, there are upper rail weight-reducing grooves on the upper rail for reducing weight, and there are up...

Embodiment 2

[0105] A spliced ring gear track, the structure of which is basically the same as that of Embodiment 1, the difference is that its levelness and posture adjustment devices are two SPS adjustment branch chains and one PRR adjustment branch chain.

[0106] Among them, the PRR adjustment branch chain includes the track fixture connected to the lower track, the horizontal horizontal axis, the horizontal adjustment connecting hinge, the upper rotation rod, the middle rotation rod, the lower rotation rod, the connecting piece of the branch chain telescopic rod and the vacuum suction cup. The upper end of the upper swing rod is equipped with a horizontal adjustment connecting hinge, and the track fixing part is connected with the horizontal adjustment connecting hinge through a horizontal horizontal axis. On the contrary, the extension or shortening of the assembly (upper rotating rod + middle rotating rod + lower rotating rod) can be realized by rotating the middle rotating rod. Th...

Embodiment 3

[0108] A spliced ring gear track, the structure of which is basically the same as that of Embodiment 1, the difference is that it uses quick-hand clamps to replace the track fixing parts and universal joints;

[0109] The fast hand fixture includes a movable part and a fixed part;

[0110] The movable part includes the handle of the quick-hand fixture, the first branch chain of the quick-hand fixture, the second branch chain of the quick-hand fixture, the third branch chain of the quick-hand fixture and the chuck, the third branch chain of the quick-hand fixture is fixedly connected with the chuck, the first branch chain of the quick-hand fixture, The second branch chain of the quick-hand fixture and the third branch chain of the quick-hand fixture are sequentially connected by the second hinge of the quick-hand fixture and the third hinge of the quick-hand fixture, and the second hinge of the quick-hand fixture is also connected with the handle of the quick-hand fixture;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com