Method for establishing scrap steel grading neural network model

A neural network model and grade classification technology, applied in the field of grade division neural network model, can solve the problems of indistinguishable division, affecting the unloading progress of the crane, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

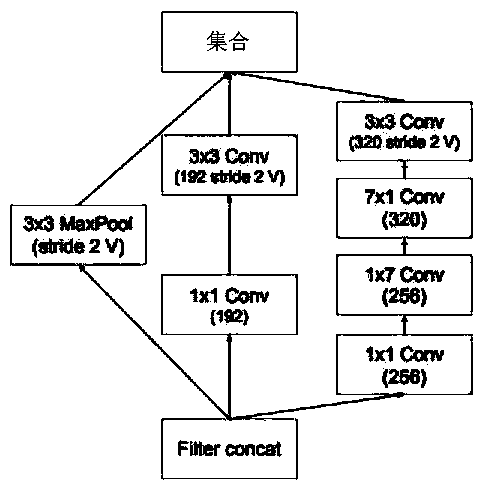

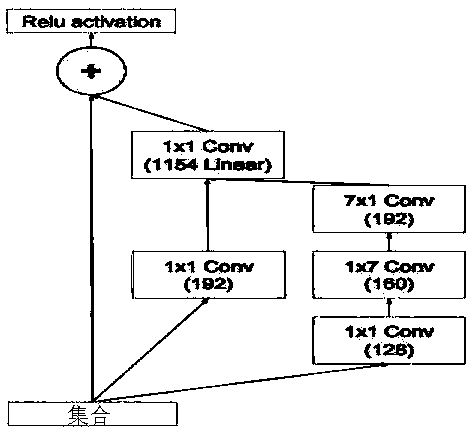

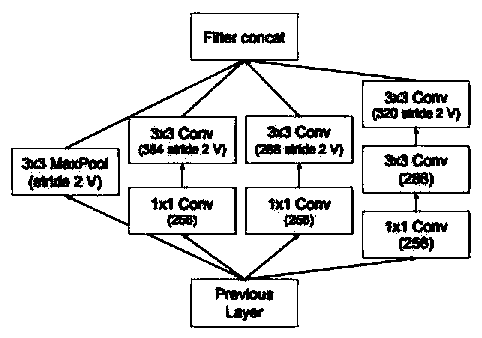

[0032] A method for establishing a neural network model for steel scrap grade classification, the model is used for grade classification detection of scrap steel storage and storage, convolutional neural network CNN (Convolutiona丨NeuralNetworks) is a known technology, and its structure follows the input layer-convolution layer-pool The layer-full connection layer and the output layer are arranged and combined to form.

[0033] The implementation of the method includes acquiring multiple images, visually determining the different steel scrap grades of the multiple images, performing preprocessing on the images to remove invalid watermarks, improving image contrast, performing image data feature extraction on image data, and extracting images of different grades Carrying out convolutional neural network learning on data features to form a graded neural network model with hierarchical classification output (ie, convolutional neural network output layer); wherein, the extraction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com