Pressure-sensitive adhesive sheet and electronic appliance

A technology of adhesive sheets and adhesive layers, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of water immersion and insufficient followability, etc., and achieve good followability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

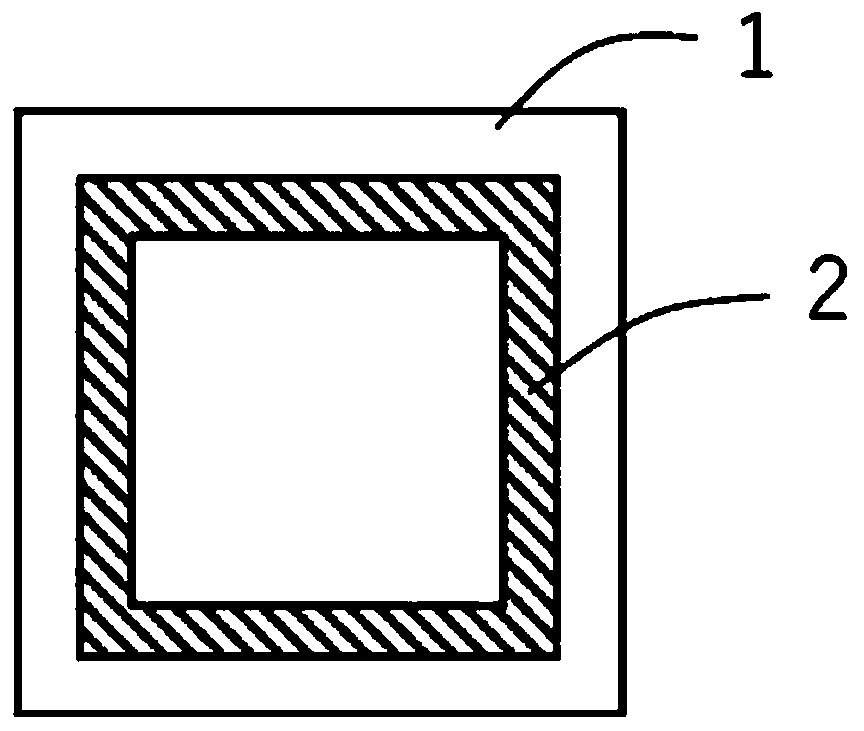

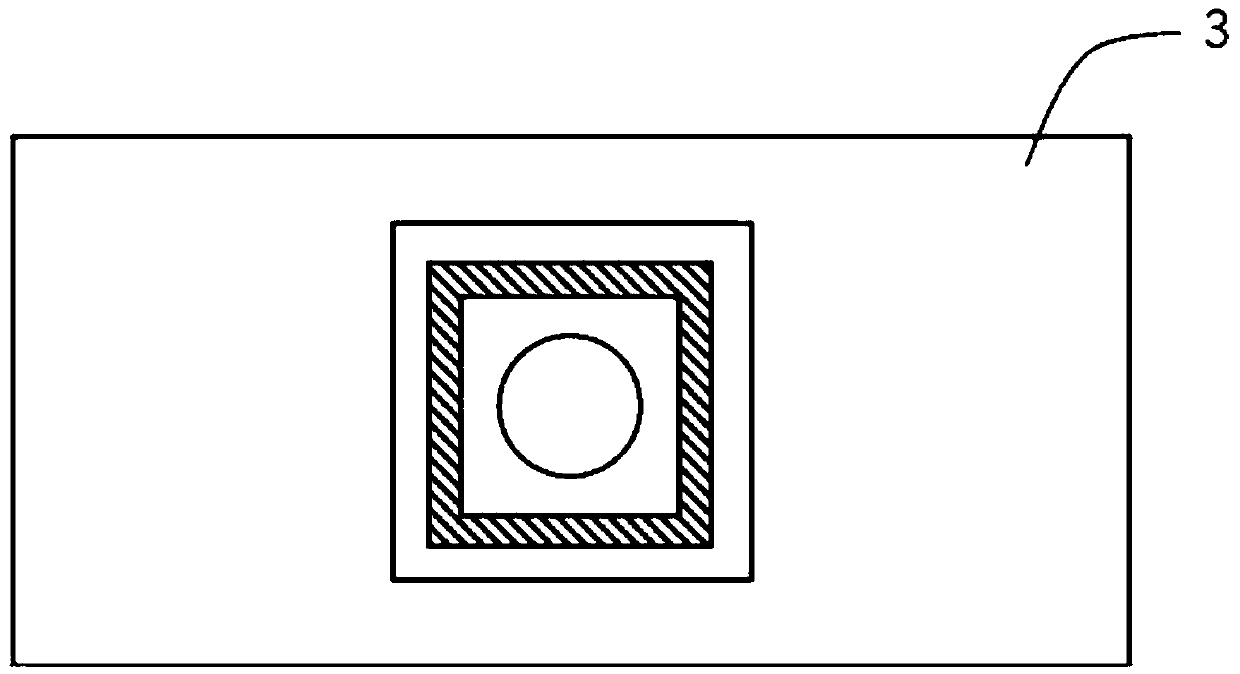

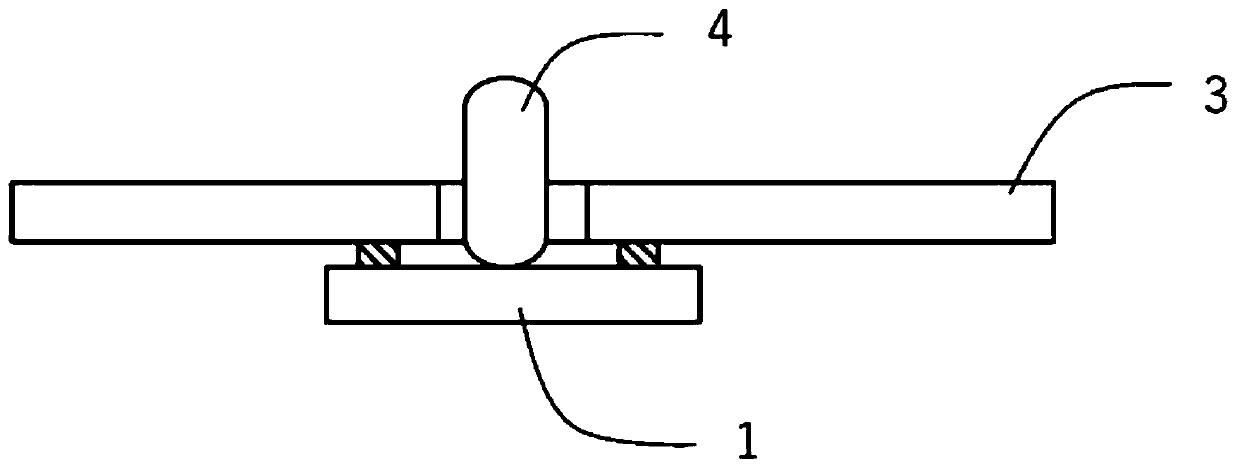

Image

Examples

Embodiment 1

[0160] On the surface of the release liner, the above-mentioned adhesive (A1) was applied using a bar coater so that the thickness of the dried adhesive layer became 50 μm, and dried at 80° C. for 3 minutes to prepare an adhesive layer.

[0161] Next, the above-mentioned adhesive layer was attached to both sides of the foam whose wetness index was adjusted to 50 mN / m by corona treatment on the surface of the foam 1 described in Table 1, and in an environment of 40° C., An adhesive sheet was produced by curing for 48 hours.

Embodiment 2

[0163] An adhesive sheet was obtained in the same manner as in Example 1 except that foam 2 described in Table 1 was used instead of foam 1 .

Embodiment 3

[0165] An adhesive sheet was obtained in the same manner as in Example 1 except that foam 3 described in Table 1 was used instead of foam 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com