Method for producing laminate, method for producing coated article, method for producing bonded structure, thermal transfer sheet, and laminate

A manufacturing method and thermal transfer layer technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problem of inability to obtain adhesive strength between resin parts and coating films, inability to obtain sufficient adhesive strength, and difficulty in bonding Solve problems such as adhesive fusion, achieve good followability, excellent appearance, and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

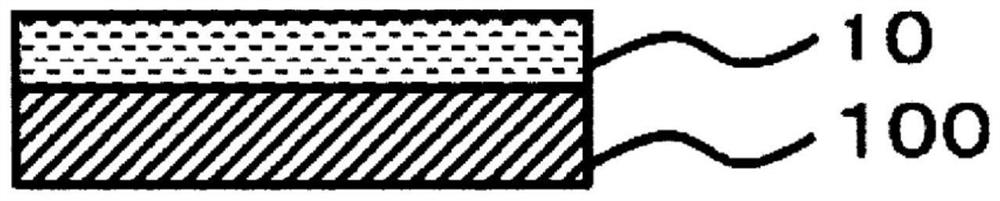

[0225] (thermal transfer sheet)

[0226] (Fine Resin FR-105 (Methoxymethylated polyamide resin) manufactured by Zinichi Co., Ltd. / manufactured by Toagosei Co., Ltd., ARUFON (registered trademark) UC-3000 (Carboxyl group-containing acrylic oligomer) ( A mixture with a mass ratio of 100 / 2)) was dissolved in a mixed solvent of ethanol (EtOH) / water / isopropanol (IPA)=60 mass % / 10 mass % / 30 mass % at 60°C to prepare a 20 mass % solution (The composition for thermal transfer layer formation).

[0227] The produced composition for forming a thermal transfer layer was filtered through a nylon mesh having a mesh size of 188 μm, and then applied to a release sheet (OT-P2171: Biaxially oriented polypropylene film manufactured by Toyobo Co., Ltd.) by a bar coater. (OPP), thickness 30 micrometers), after air-drying, it further dried at 100 degreeC for 1 minute with a constant temperature dryer, and produced the thermal transfer sheet provided with the thermal transfer layer on the releas...

Embodiment 2~16、 comparative example 3~5

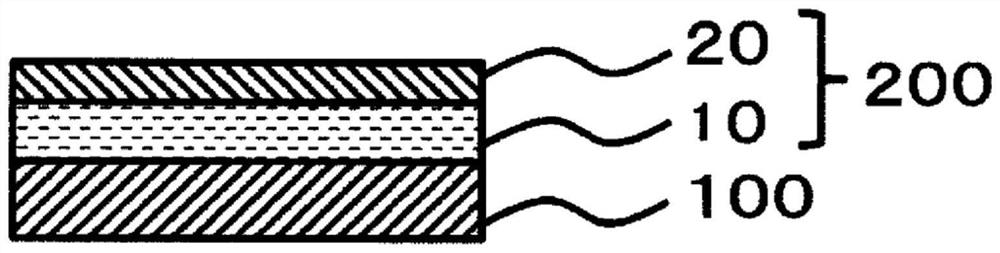

[0269] A thermal transfer sheet, a laminate (1), a thermal transfer sheet, a laminate (1), The structure, the coated object, and the laminated body (2) were joined, and each measurement and each evaluation were performed in the same manner as in Example 1.

[0270] In addition, Example 1 differs from the thickness of the thermal transfer layer of Examples 5-7. In addition, the same thermal transfer sheet was used in Example 1 and Example 8, but the molding temperature Tβ°C was different. In addition, Example 3 and Example 10 used the same thermal transfer sheet, but the molding temperature Tβ°C was different. In addition, the same thermal transfer sheet was used in Example 4 and Example 9, but the molding temperature Tβ°C was different. In addition, in Examples 12 to 14, the same thermal transfer sheet was used, but the molding temperature Tβ°C was different.

[0271]

[0272] 5 mg of the resin before curing of the thermosetting resin was cut out and measured by DSC (diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com