Adhesive tape film, and adhesive tape

A technology of adhesive tape and film, applied in the direction of adhesive type, nitrile copolymer adhesive, film/sheet adhesive, etc., which can solve the problem of cracking of the treatment layer, small elongation, and inability to follow the treatment layer Stretch and other problems, to achieve the effect of inhibiting adhesion, good fusion, and good followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited by these examples. Parts are by weight. In addition, the amount of the reagent supplied in the form of a solution is represented by the amount of solid content remaining after volatilizing the solution (solid content conversion amount).

[0112]

[0113] The maximum elongation was measured with an INSTRON type tensile tester (manufactured by Shimadzu Corporation, Autograph) in accordance with JIS-K-7127. Specifically, after placing a sample having a width of 20 mm x a length of 100 mm at a distance between chucks of 50 mm, it was stretched at a tensile speed of 0.3 m / min, and the value at breakage was measured.

[0114]

[0115] The elastic modulus was measured in accordance with JIS-K-7127.

[0116]

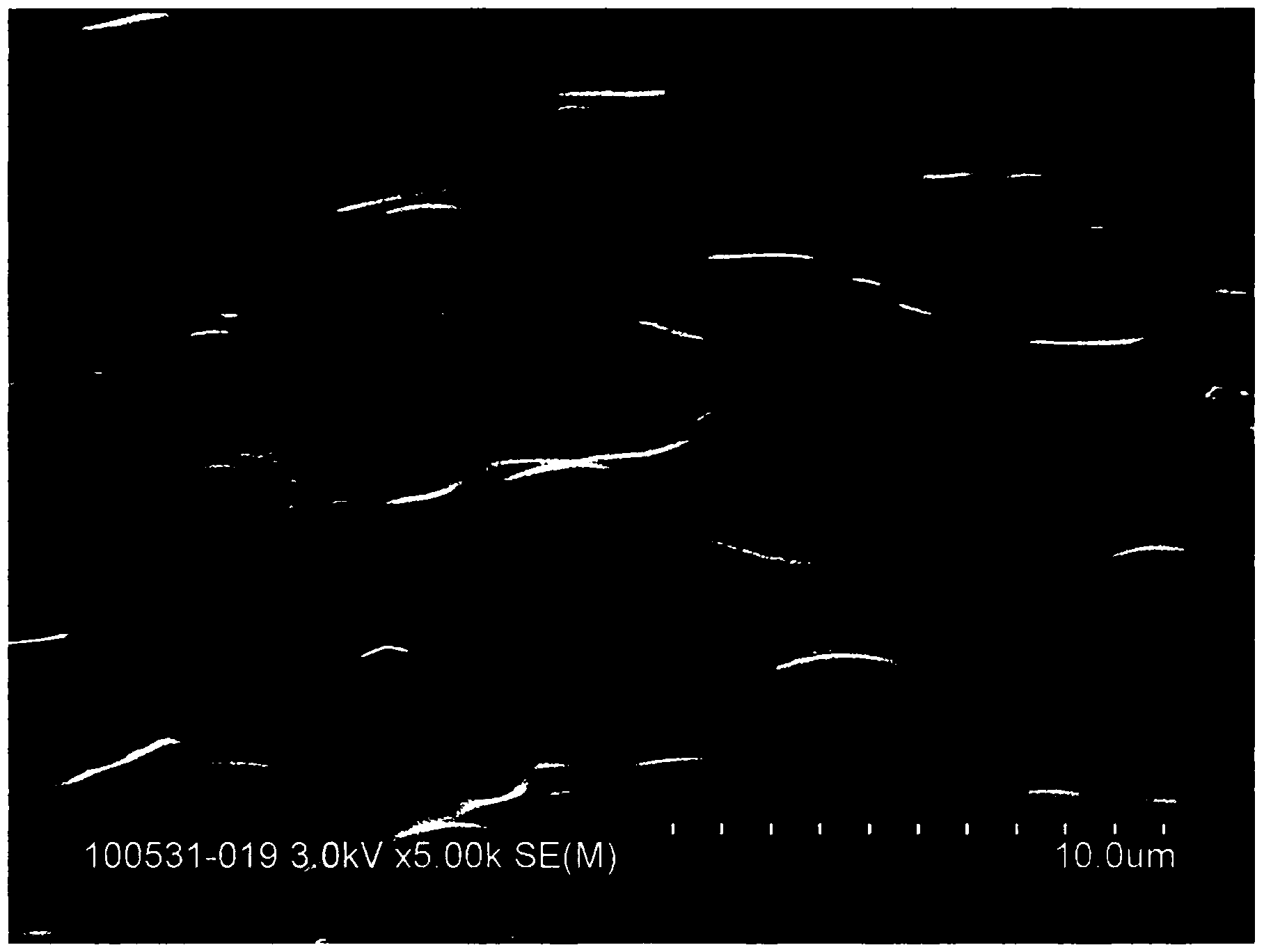

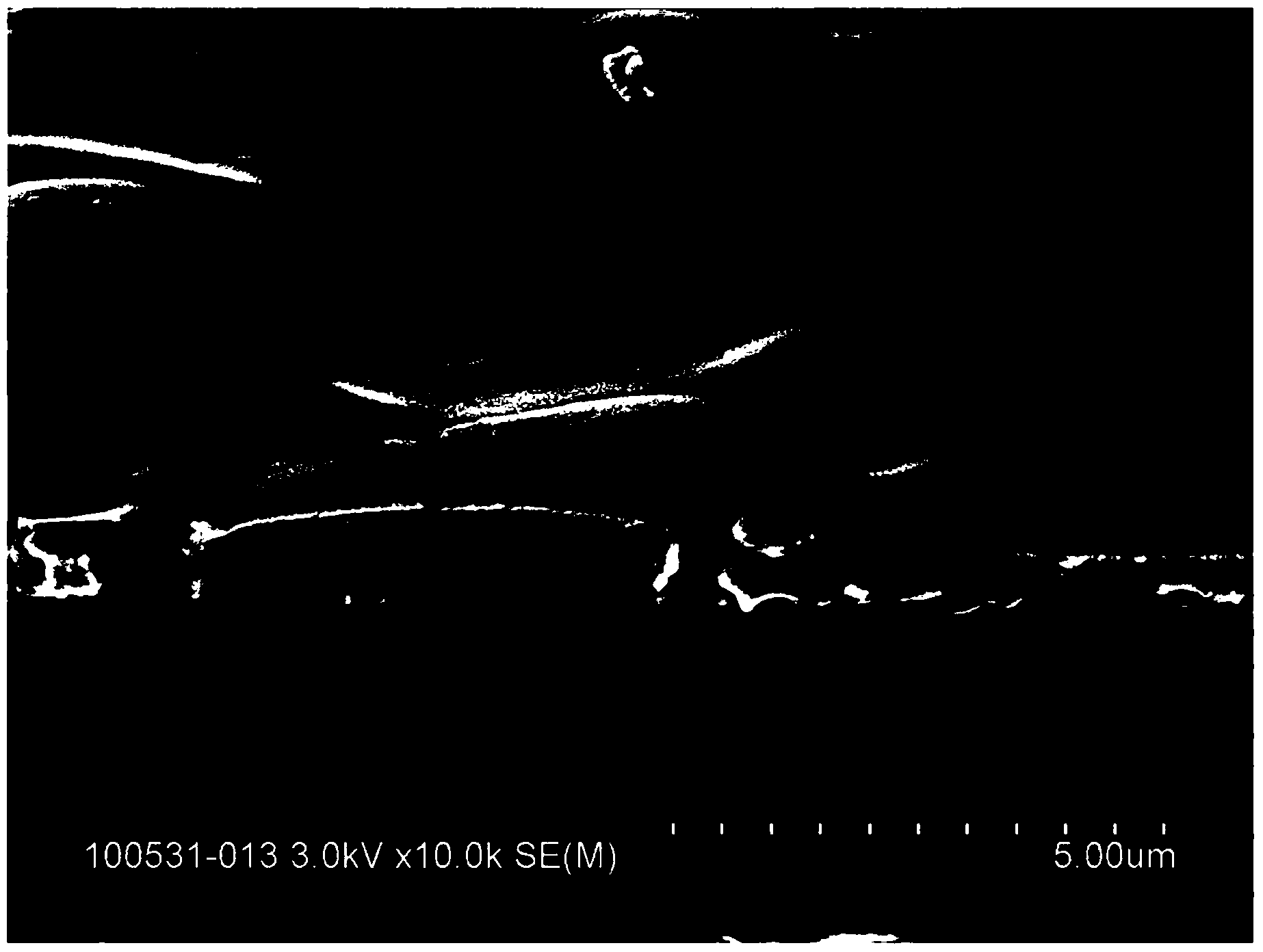

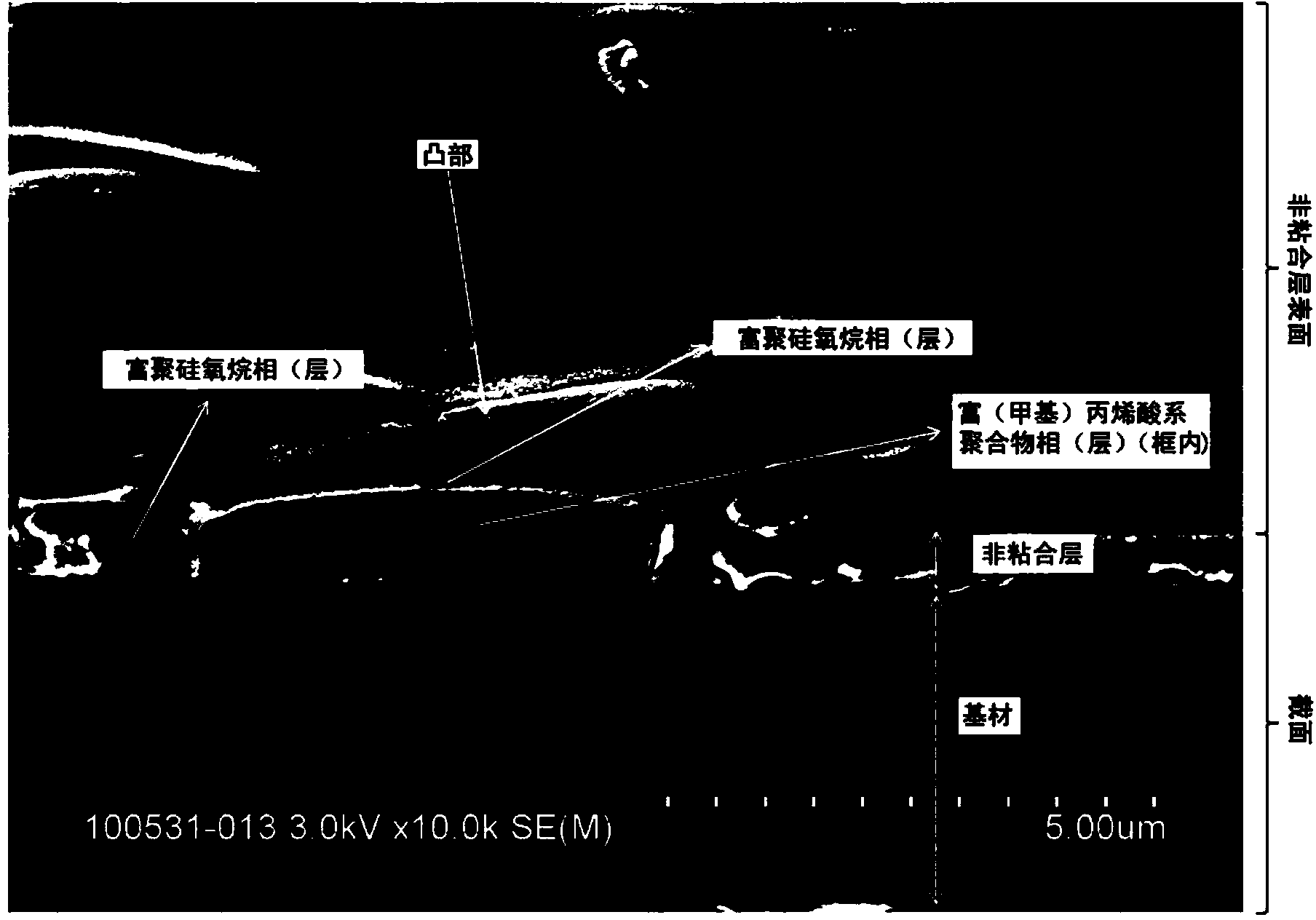

[0117] (Observation by SEM)

[0118] After processing so that the cross-section of the non-adhesive layer can be observed, the morpholog...

manufacture example 1

[0154] [Manufacturing example 1]: Manufacture of plastic film

[0155] Manufactured by calendaring method Contains 27 parts by weight of DOP plasticizer (bis(2-ethylhexyl phthalate), manufactured by J-PLUS Co., Ltd.) with respect to 100 parts by weight of polyvinyl chloride with a degree of polymerization P=1050 soft polyvinyl chloride film. The flexible polyvinyl chloride film had a thickness of 70 µm, an elastic modulus (MD) measured in accordance with JIS-K-7127 of 250 MPa, and a maximum elongation (MD) measured in accordance with JIS-K-7127 of 400%. In addition, the surface roughness (arithmetic mean surface roughness Ra) immediately after production was 0.1 μm.

Embodiment 1

[0157] 60 parts by weight of polysiloxane resin (KS-723A, manufactured by Shin-Etsu Chemical Industry), 40 parts by weight of polysiloxane resin (KS-723B, manufactured by Shin-Etsu Chemical Industry), acrylic copolymer (methyl methacrylate (MMA) / butyl acrylate (BA) / hydroxyethyl acrylate (HEA)=90 / 10 / 10) 50 parts by weight, tin-based catalyst (Cat-PS3, manufactured by Shin-Etsu Chemical Co., Ltd.) 10 parts by weight were mixed in a solution state , to obtain the mixed solution (1). The mixing ratio of the polysiloxane in the mixed solution (1) and the (meth)acrylic polymer is polysiloxane:(meth)acrylic polymer=2:1 by weight ratio. In addition, the calculated Tg of the acrylic copolymer is 67.8°C, and the SP value is 10.7 (cal / cm3)0.5

[0158] .

[0159] The above-mentioned mixed solution (1) was coated on one side of the flexible polyvinyl chloride film produced in Production Example 1 to form a non-adhesive layer having a thickness of 1.0 μm and an arithmetic mean surface rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com