Hot and cold water mixing faucet

A technology of hot and cold water, mixing valve, applied in multi-way valve, valve device, valve details and other directions, can solve the problems of increasing the compression margin of O-ring, low followability of temperature sensing spring, and reducing temperature regulation performance, etc. Achieve the effect of reducing sliding resistance, good followability, and improving temperature regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] In Comparative Example 1, the O-ring supporting the control valve body was made of hexafluoropropylene-vinylidene fluoride copolymer (FKM) (hardness 70°, rebound rate 14%). Noise generation was investigated under the same conditions as in Comparative Example 1. The results are shown in Table 1.

Embodiment 2

[0098] Noise generation was examined under the same conditions as in Example 1 except that the compression ratio of the O-ring 10 in Example 1 was set to 3.3%. The results are shown in Table 1.

Embodiment 3

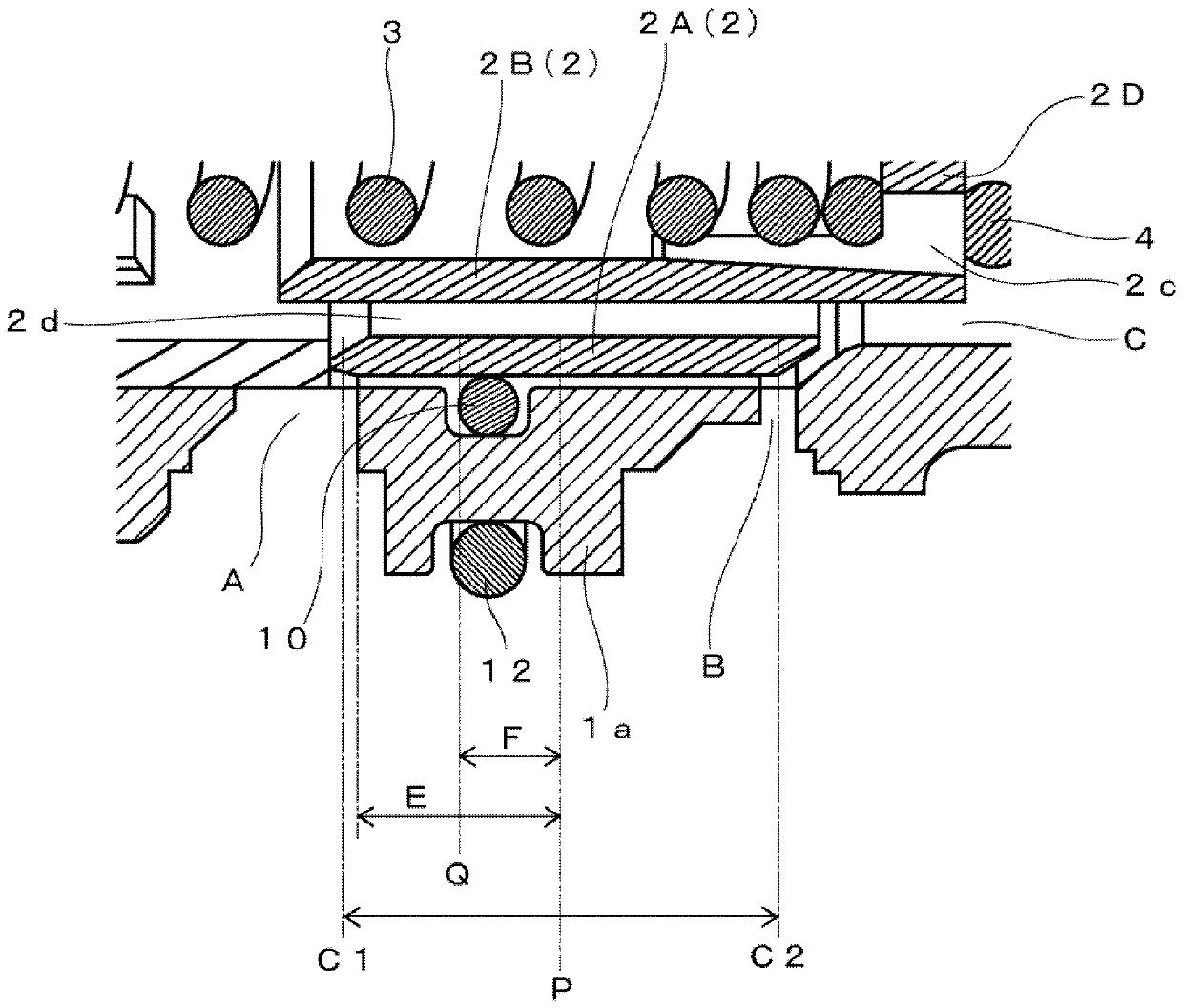

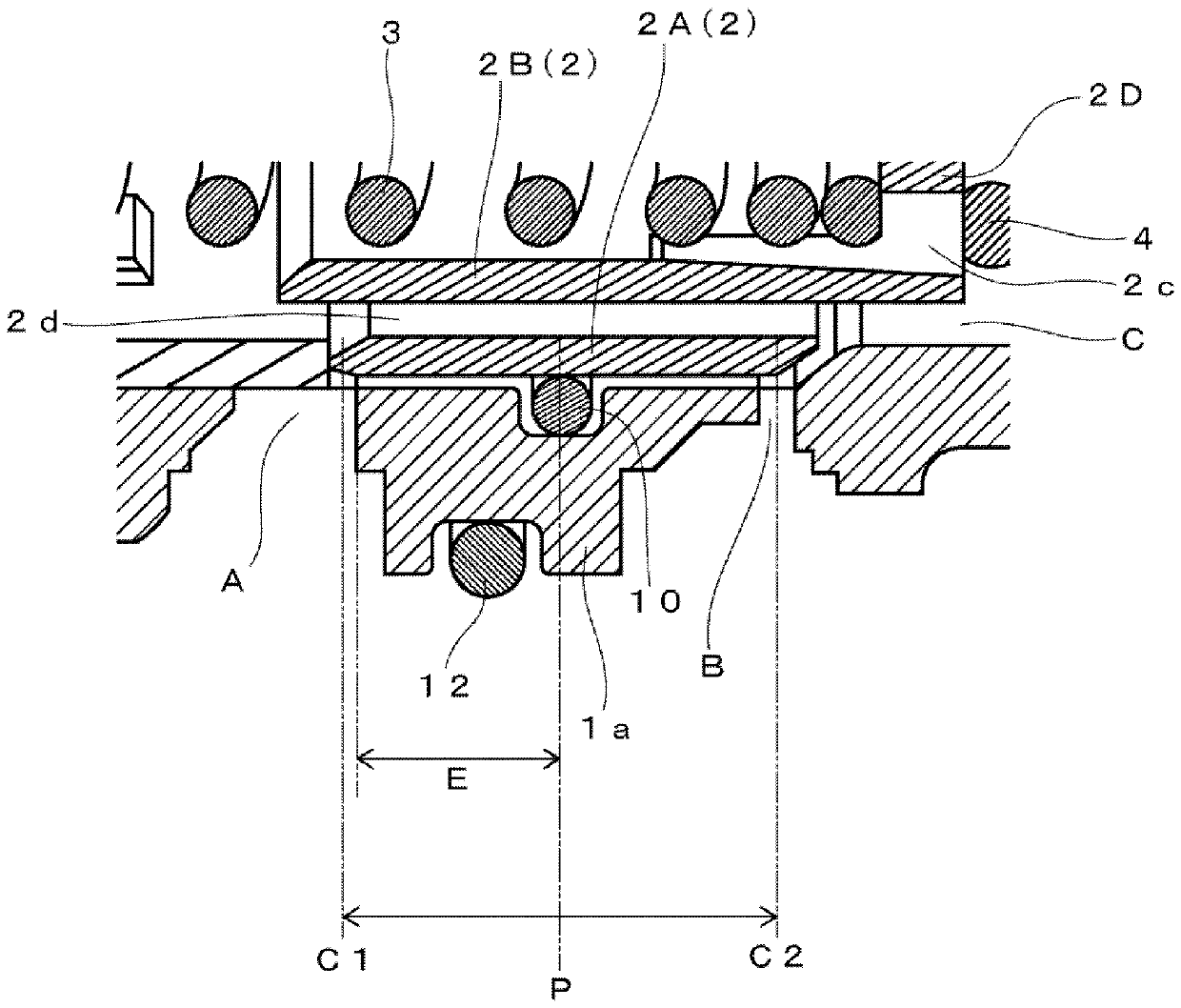

[0100] Such as Figure 6 As shown, the arrangement of the O-ring 10 in Example 1 was changed from the intermediate point P to the side of the hot water inlet A (in the area F), and the noise was investigated under the same conditions as in Example 1. produce. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com