Efficient pulverizing device for crude medicine processing

A high-efficiency pulverization and medicinal material processing technology, applied in grain processing and other directions, can solve the problems of incomplete pulverization of medicinal materials, reduced pulverization efficiency, and small pulverizing range, and achieve the effect of improving pulverizing efficiency, expanding scope, and expanding pulverizing scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

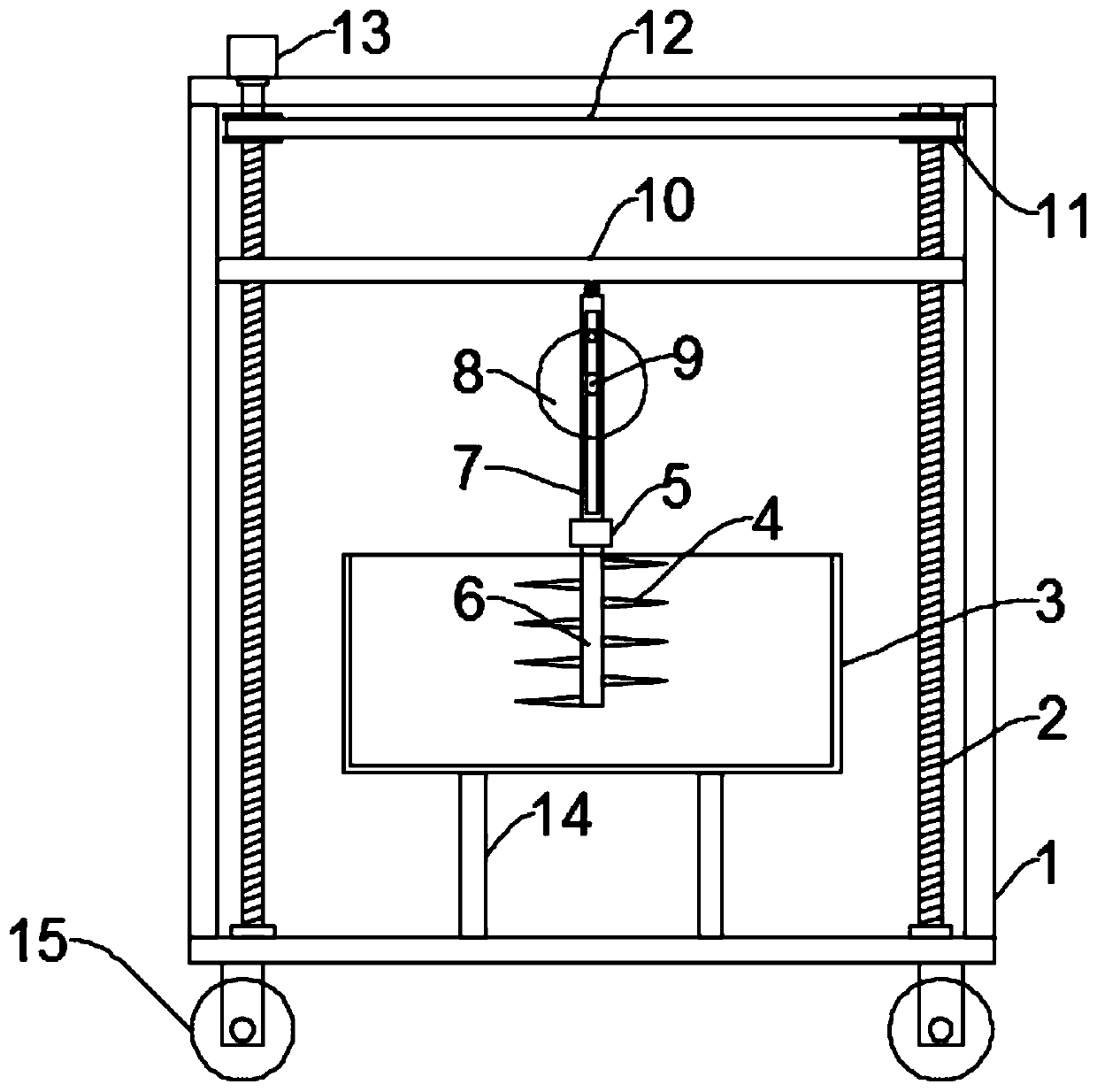

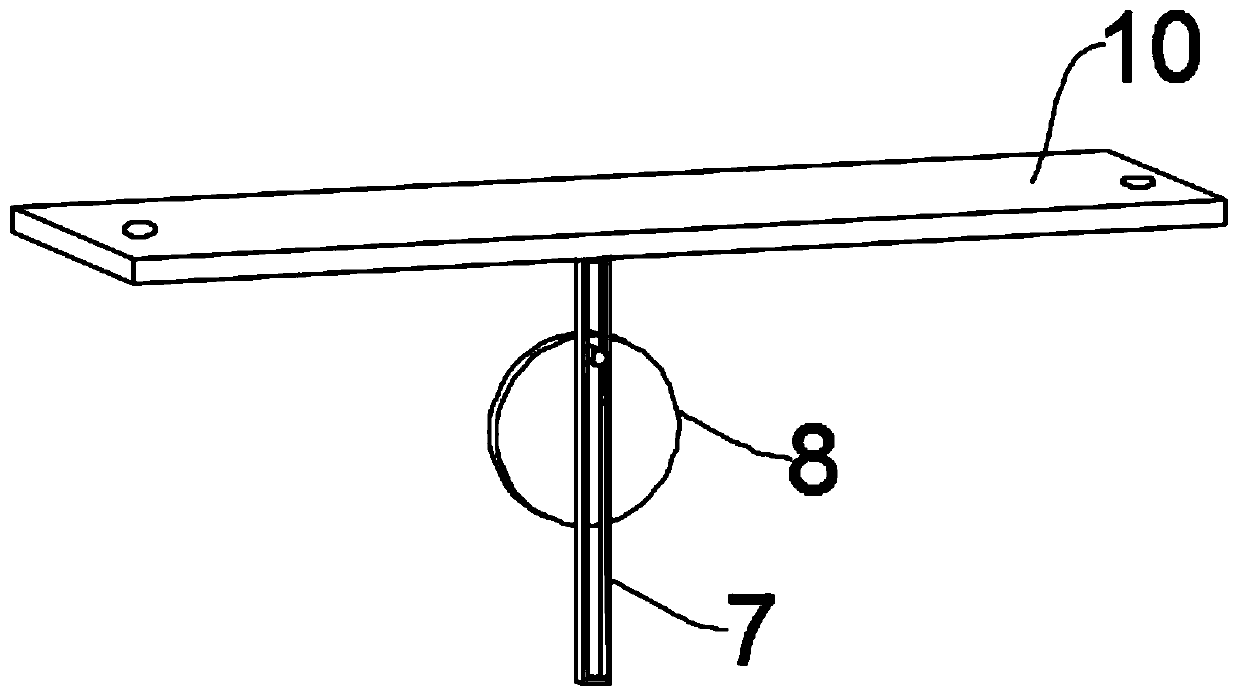

[0024] see Figure 1~2 , in an embodiment of the present invention, a high-efficiency crushing device for medicinal material processing, including a frame 1, a medicinal material frame 3 and a crushing unit, the bottom of the frame 1 is evenly and symmetrically equipped with supporting legs, and the bottom end of the supporting legs is equipped with rollers 14, The roller 14 is a self-locking roller, which facilitates the movement of the device. The medicinal material frame 3 is installed on the frame 1 through the symmetrically fixed support rod 14 at the bottom, and a crushing unit is arranged in the medicinal material frame 3. The crushing unit includes The first motor 5, the rotating shaft 6 and the first crushing blade 4, the output shaft of the first motor 5 is driven to connect the rotating shaft 6, the rotating shaft 6 is preferably fixedly connected with the output shaft of the first motor 5 through a shaft coupling, and the rotating shaft 6 is from top to bottom A pl...

Embodiment 2

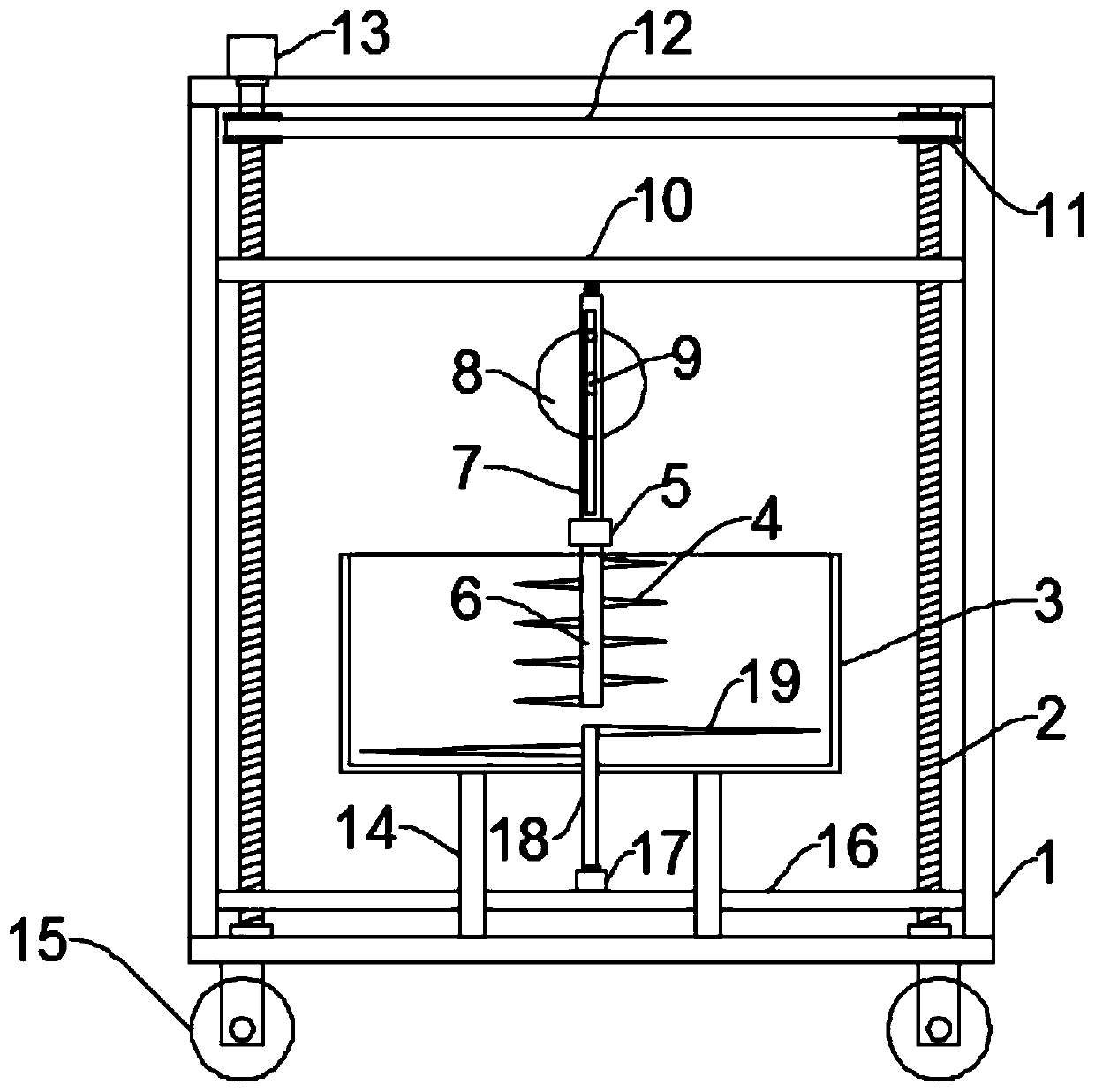

[0026] see image 3 , the difference between the embodiment of the present invention and embodiment 1 is that a second mounting plate 16 is connected between the lower parts of the two threaded rods 2, the threaded rods 2 are screwed to the second mounting plate 16, and the second mounting plate 16 is installed There is a third motor 17, a crushing shaft 18 is installed on the output shaft of the third motor 17, the top of the crushing shaft 18 extends to the bottom of the inner cavity of the medicinal material frame 3, and the bottom of the medicinal material frame 3 is provided with a through hole for the crushing shaft 18 to pass through. The shaft 18 is matched with the through hole clearance, and the top of the crushing shaft 18 is fixed with a second crushing blade 19. The second crushing blade 19 is preferably fixed with the crushing shaft 18 by welding, and the third motor 17 is started, and the third motor 17 drives the crushing shaft 18 and the second crushing shaft. ...

Embodiment 3

[0028] see Figure 4, the embodiment of the present invention differs from Embodiment 1 in that a pushing mechanism is installed on both side walls of the medicinal material frame 3, and the pushing mechanism includes a pushing plate 20, a fourth motor, a drive plate 22, a movable Bar 23 and installation bar 21, the 4th motor is installed on the medicinal material frame 3 sidewalls, and the output shaft of the 4th motor is equipped with driving disk 22, and driving disk 22 front side is matched with being connected with movable rod 23, and movable rod 23 two ends A guide rod is pierced, and the guide rod is fixed on the side wall of the medicinal material frame 3. The outer ring of the front end of the driving disk 22 is integrally provided with a pin shaft, and the movable rod 23 is provided with a chute for the pin shaft to insert and slide. One side of the medicinal material frame 3 is fixed with a mounting rod 21, and the other end of the mounting rod 21 runs through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com