Train whole-vehicle shot blasting derusting machine

A rust remover and train technology, which is applied to abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of the inability to guarantee the surface finish of the whole train, the difficulty of recycling the shot, and the high work intensity. To achieve the effect of shot blasting and rust removal, ensuring surface finish and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

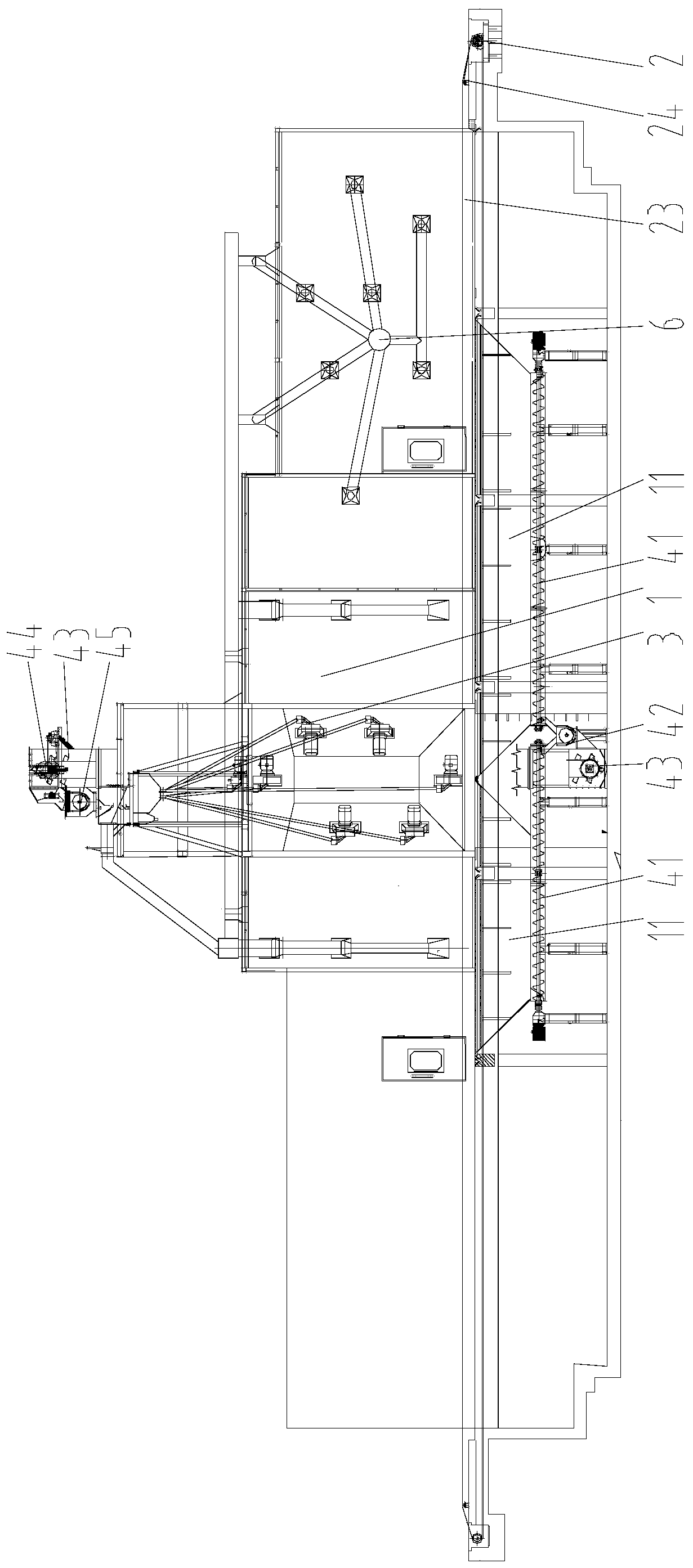

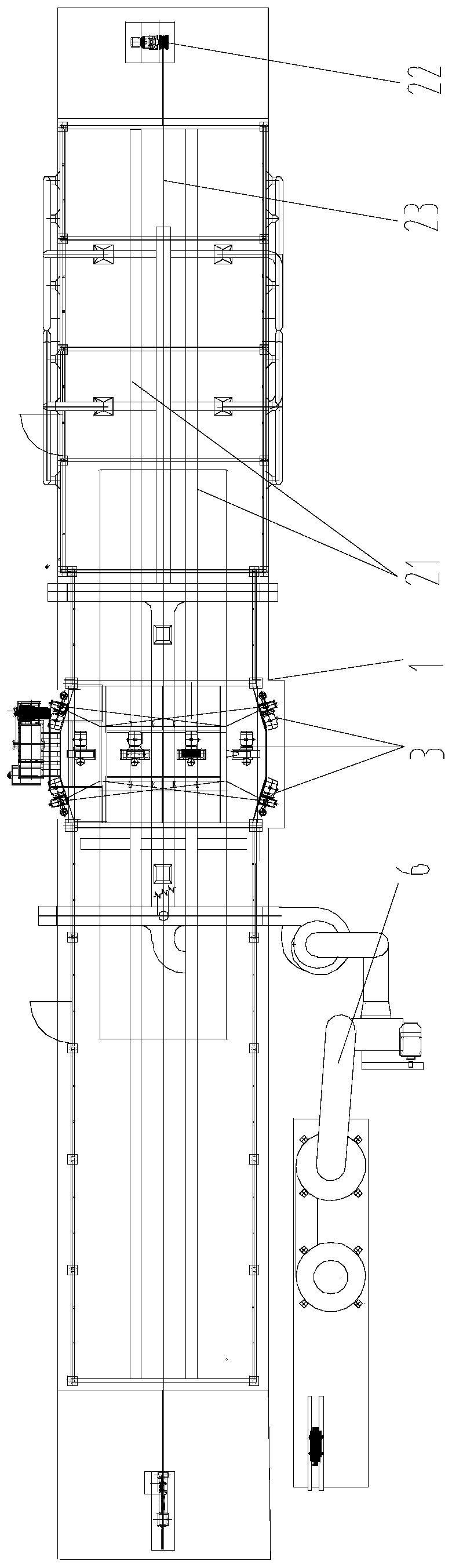

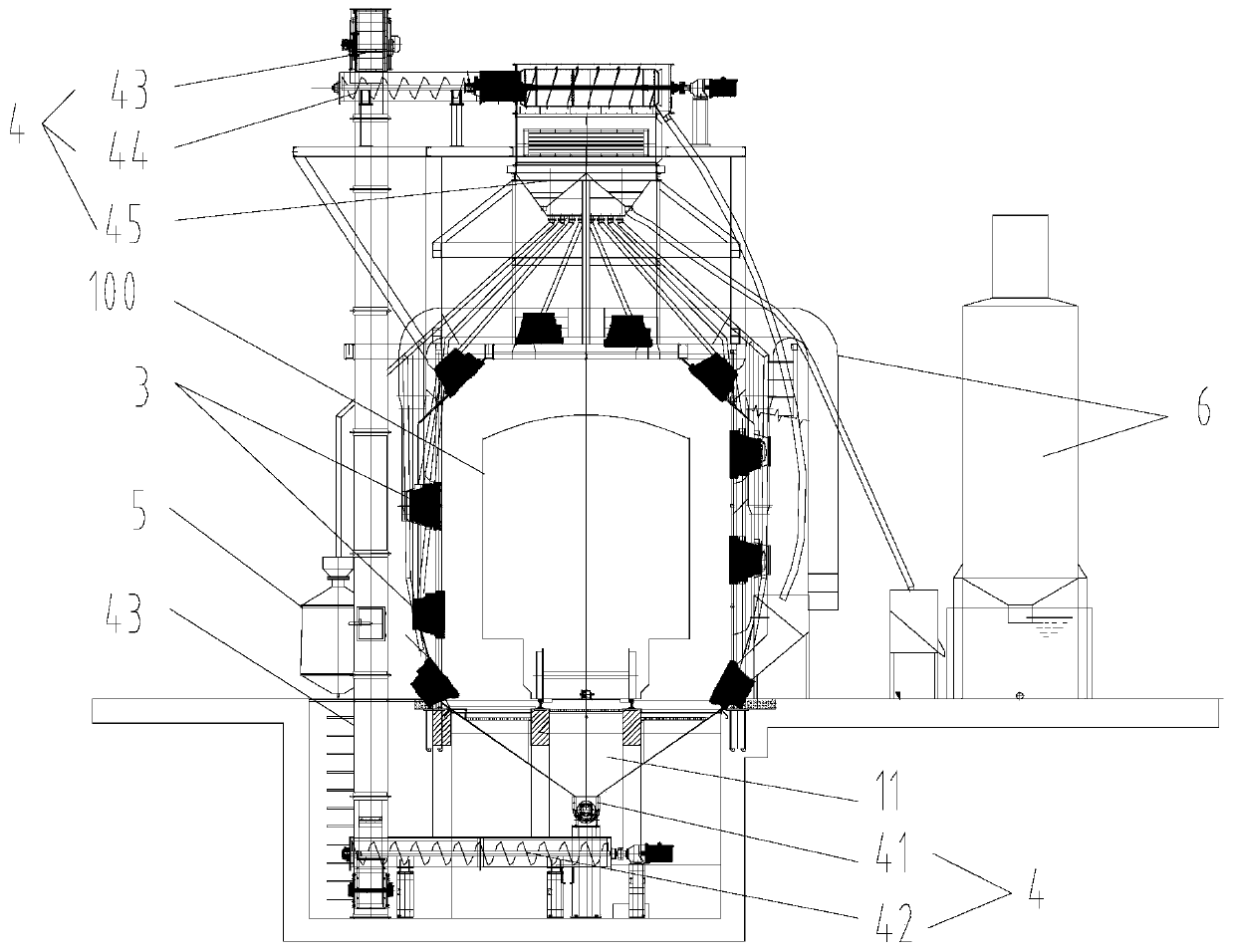

[0026] See Figure 1 to Figure 3 , a shot blasting derusting machine for a train vehicle, comprising a shot blasting chamber 1, a traction device 2, a shot blasting device 3, a shot recycling purification system 4, a supplementary spraying system 5 and a dust removal system 6. in:

[0027] see you again Figure 1 to Figure 3 , the shot blasting chamber 1 is in the shape of a hollow shell, and the bottom surface of the shot blasting chamber 1 is provided with a collection chamber 11, the collection chamber 11 is in the shape of an inverted diamond, and the collection chamber 11 communicates with the interior space of the shot blasting chamber 1; The skeleton of the cleaning chamber 1 is welded by ordinary section steel and plates, and the inner wall of the shot blasting cleaning chamber 1 is equipped with a wear-resistant guard plate. In this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com