Multi-angle rotary wrench

A multi-angle, wrench technology, applied in the field of hardware, can solve the problems of the wrench being unusable, shortening the handle, affecting the labor-saving effect, etc., so as to reduce the work burden, improve work efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

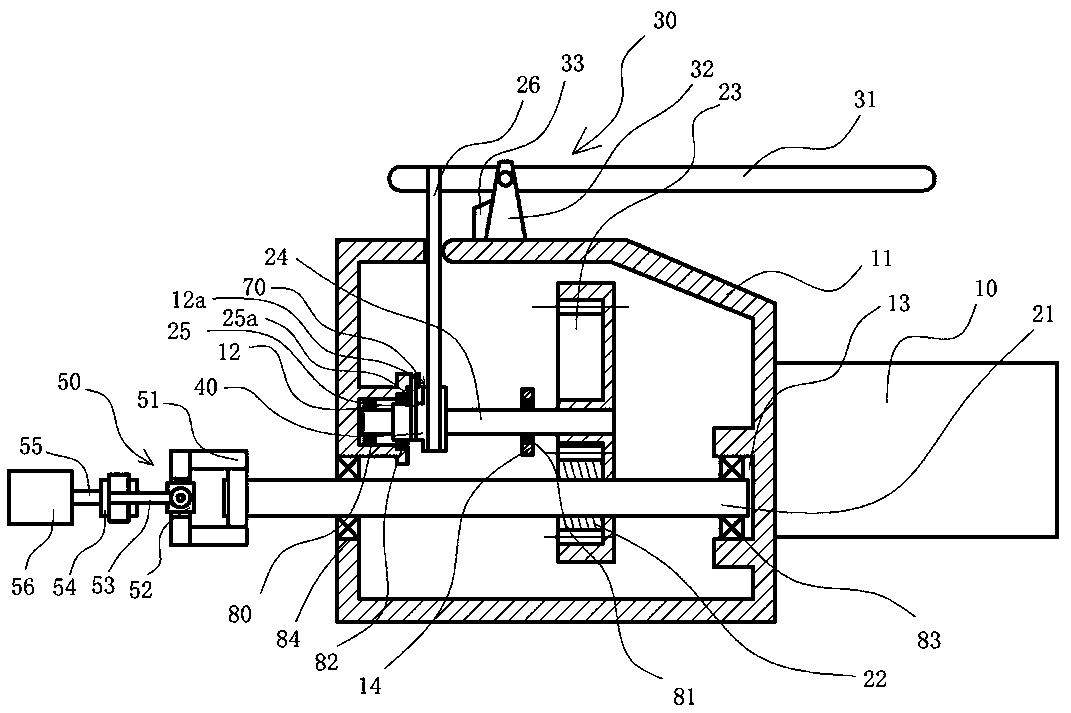

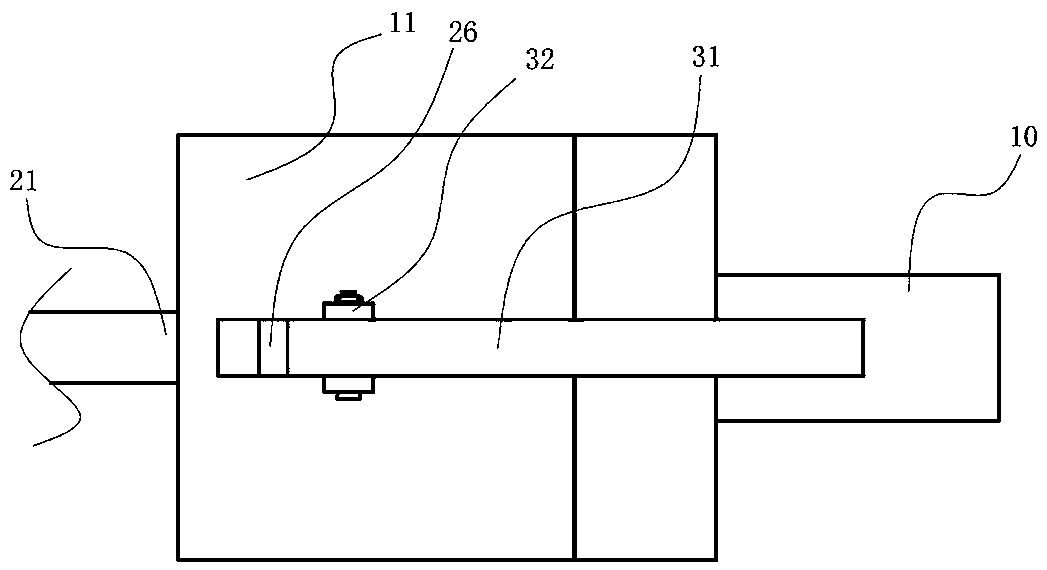

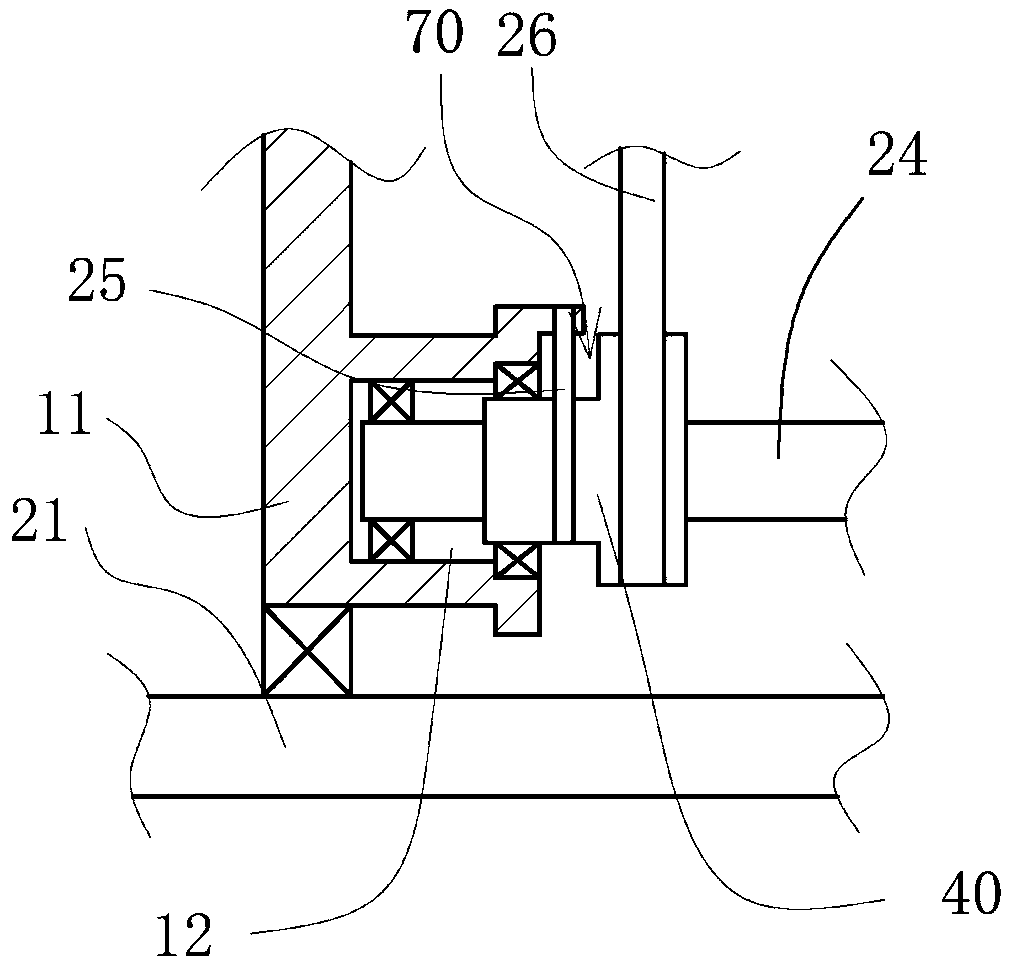

[0026] like figure 1 , figure 2 and image 3As shown, the multi-angle rotary wrench of the present invention includes a housing 11, the rear end of the housing 11 is provided with a handle 10, the front end of the inner cavity of the housing 11 is provided with a front groove 12, and the middle end of the inner cavity of the housing 11 is provided with a bearing groove 14, The center of the front groove 12 and the center of the bearing groove 14 are on the same axis, and the front groove 12 is provided with a drive shaft 24, the drive shaft 24 passes through the bearing groove 14, and one end of the drive shaft 24 is rotatably connected with the front groove 12 through a bearing one 80 , the driving shaft 24 is rotatably connected to the bearing groove 14 through the bearing 2 81, the other end of the driving shaft 24 is connected with the acceleration gear set 20, the other end of the acceleration gear set 20 is connected with the transmission shaft 21, and the rear end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com