Double-station woven bag cutting device

A woven bag, double-station technology, applied in the field of double-station woven bag incision device, can solve the problems of not neat plastic woven bag mouth, low work efficiency, incision burr, etc., to achieve novel design, improve incision efficiency, high efficiency The effect of cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

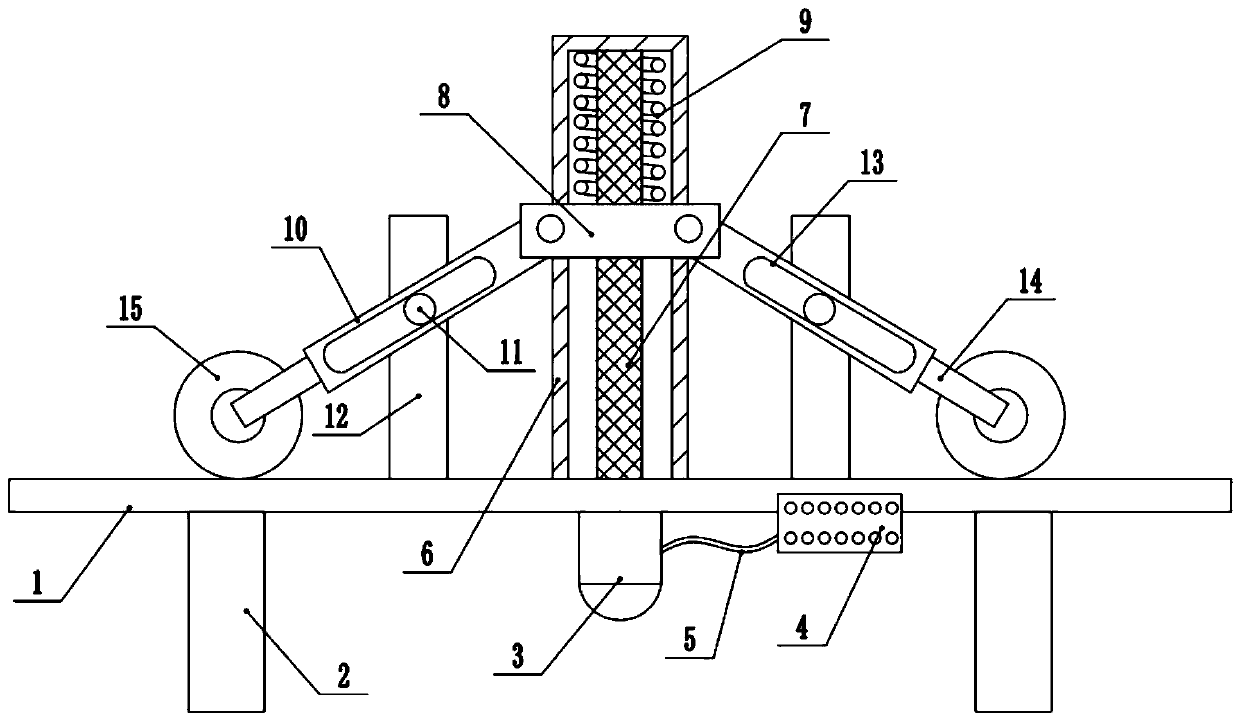

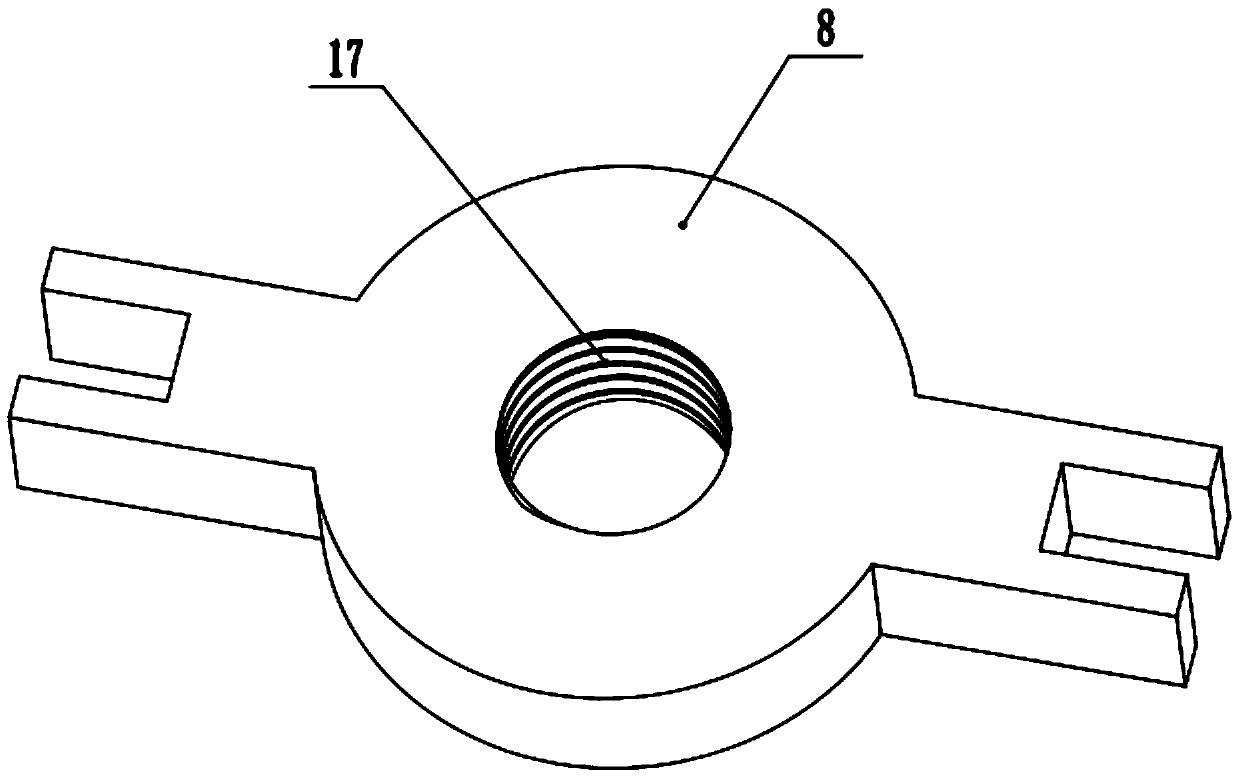

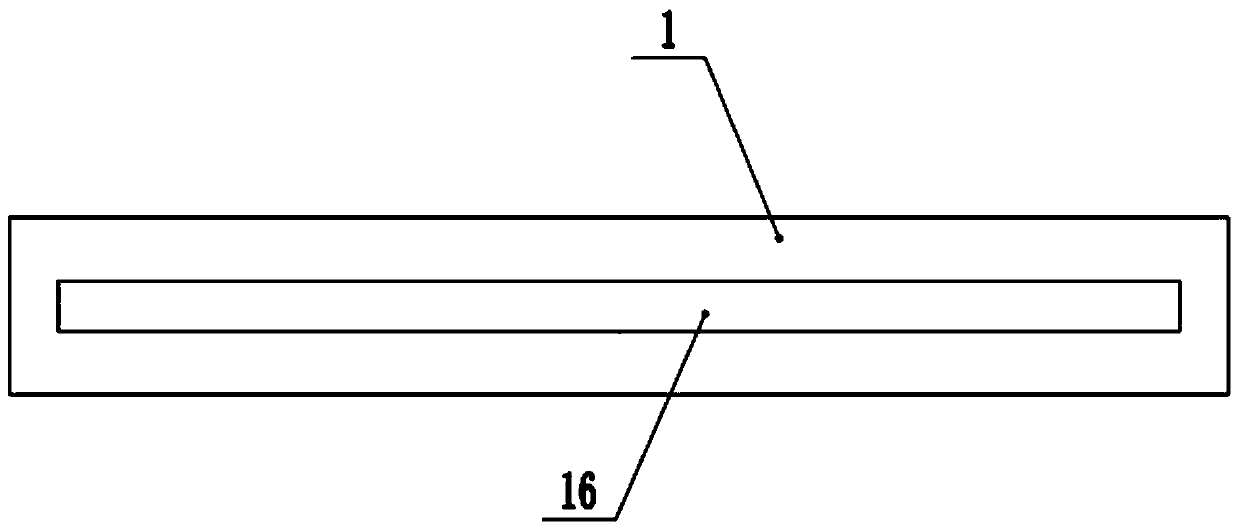

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a double-station woven bag incision device includes a fixed bottom plate 1, and the middle part of the upper end of the fixed bottom plate 1 is provided with a chute 13 that cooperates with a cutter 15, and the cutter 15 can be moved along the The chute 13 moves left and right, and the support legs 2 are installed on both sides of the lower end of the fixed base plate 1 to realize the support and fixation of the fixed base plate 1. A fixed cylinder 6 is installed in the middle of the upper end of the fixed base plate 1, and a lead screw 7 is installed inside the fixed cylinder 6. Moving block 8 is installed in leading screw 7 middle parts, and moving block 8 two ends are hinged with swing bar 10, and swing bar 10 middle part is provided with chute 13, and chute 13 inside is provided with slide column 11, and described swing bar 10 can pass through chute 13. Move along the sliding column 11 to play a posit...

Embodiment 2

[0027] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the outer side of the lead screw 7 between the moving block 8 and the inner top end of the fixed cylinder 6 is covered with a buffer spring 9, which is slowly The spring 9 makes the moving block 8 not shake in a large range during the up and down movement, thereby ensuring the stability of the whole cutter 15 when working.

[0028] In the present invention, when working, the woven bag that needs to be cut is placed near the upper end of the fixed base plate 1 near the cutter 15, and then the drive motor 3 is started, and the drive motor 3 drives the lead screw 7 to rotate, so that the moving block 8 moves downward, and then the drive motor 3 is driven to rotate. The swing rod 10 slides along the sliding column 11 through the action of the chute 10, so that the cutting knife 15 moves to the outside along the knife groove 16 to realize the incis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com