Packaging equipment and packaging forming technology for folding packaging boxes

A technology of packaging equipment and packaging boxes, applied in the field of packaging, can solve problems such as not suitable for mass production, complicated equipment structure, and hindering products from advancing into packaging boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

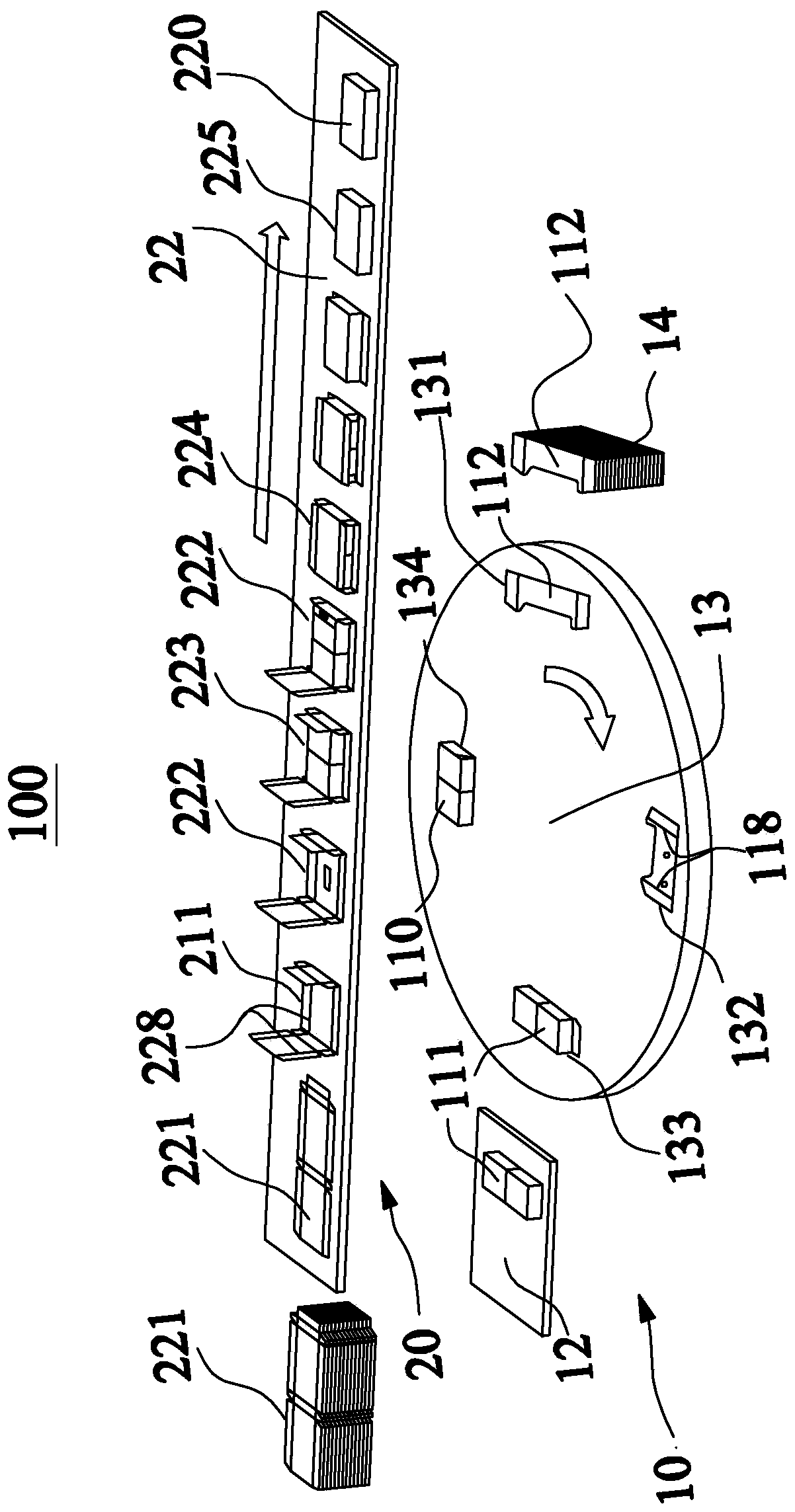

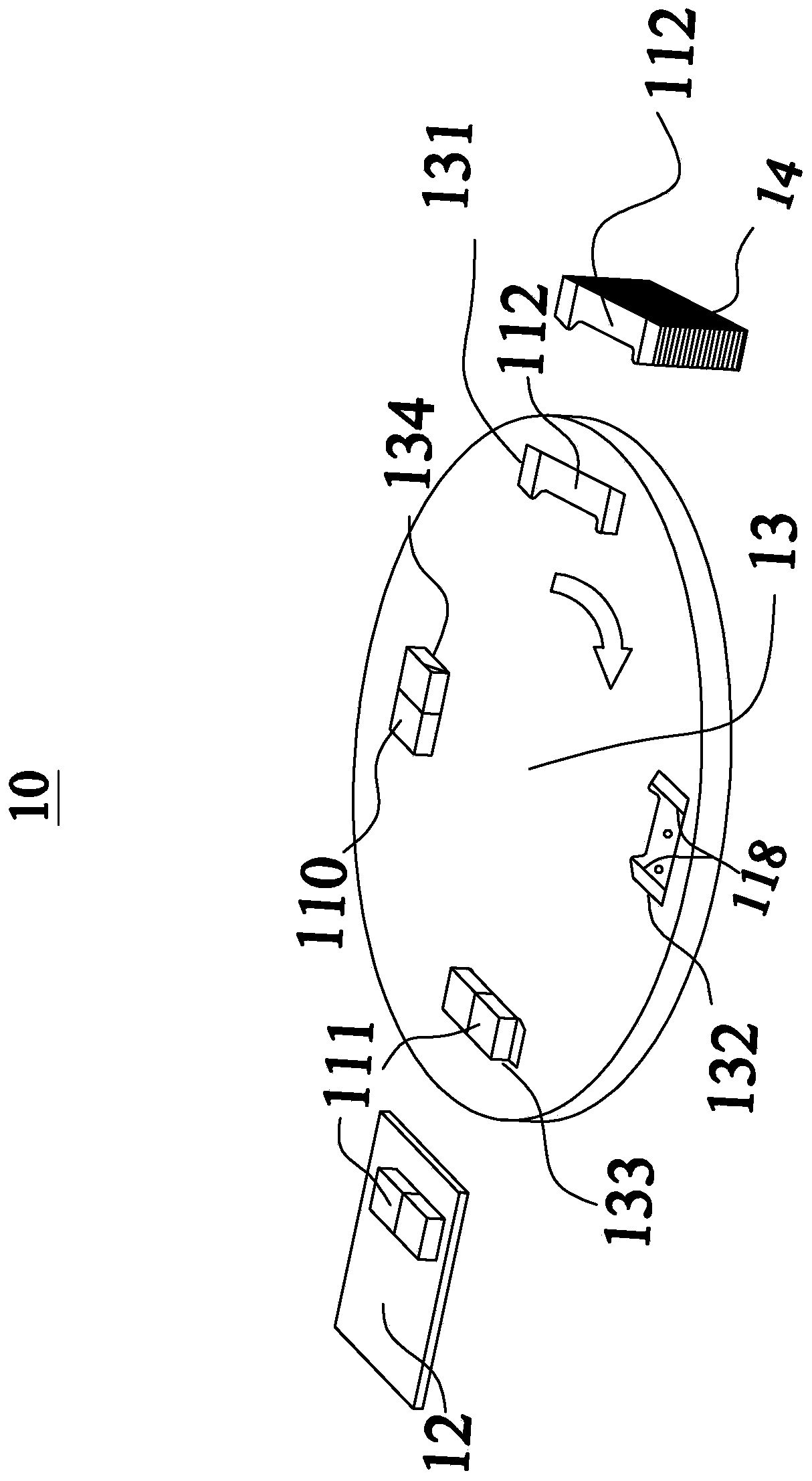

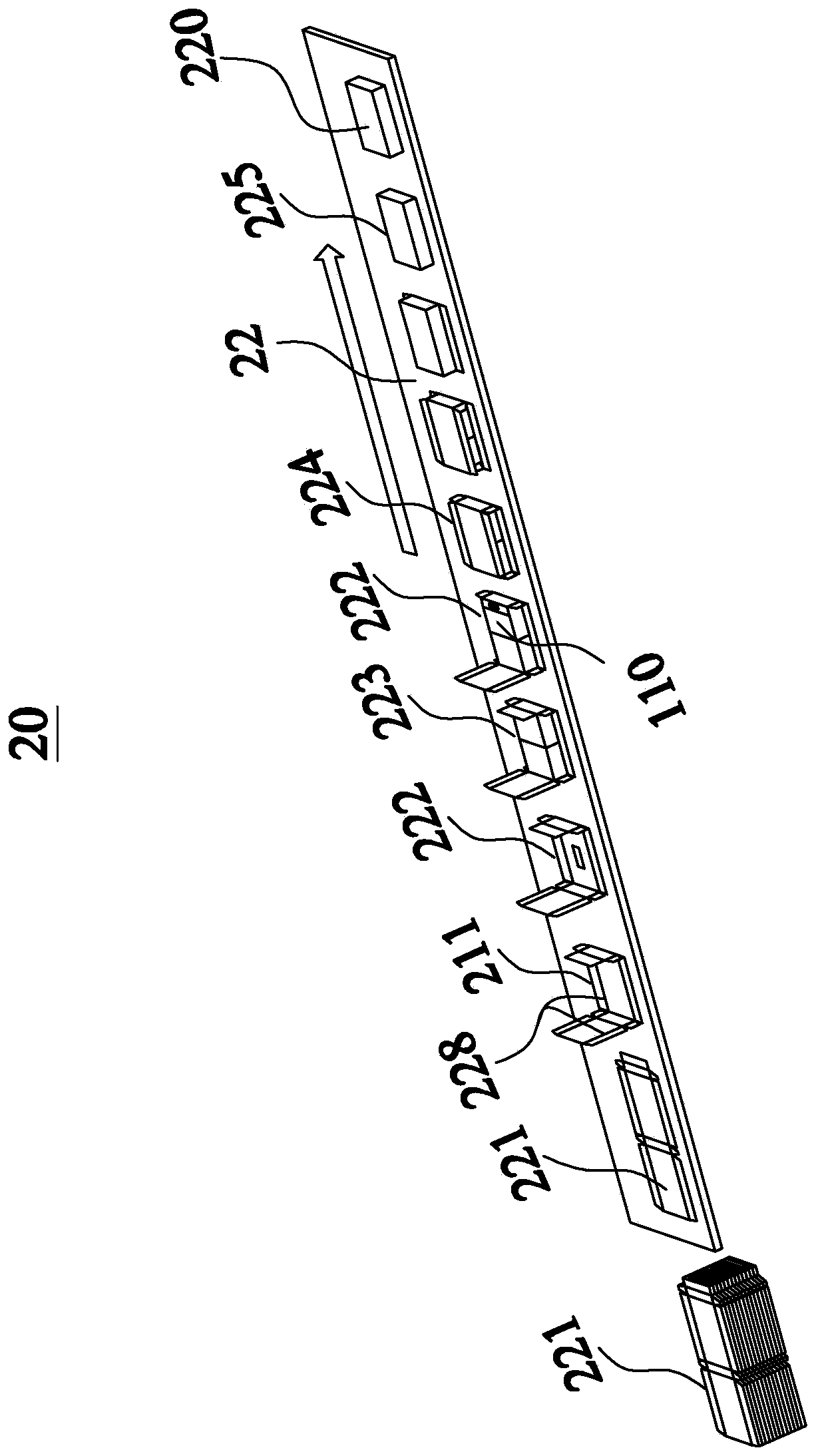

[0029] see figure 1 , 2 and 3, showing the structure of a packaging device 100 for a folding packaging box, the packaging device 100 includes an inner packaging system 10 and an outer packaging system 20, and the inner packaging system 10 is used to combine at least one inner packaging box 111 into a The inner liner card 112 forms the inner packaging 110, and the outer packaging system 20 is used to combine the inner packaging 110 with the carton paper card 221 to form an outer packaging 220, and the inner packaging system 10 includes a first conveyor belt 12, an inner packaging Operation turntable 13, lining paper silo 14 and several first manipulators, the inner packaging operation turntable 13 is sequentially provided with a retrieving station 131, a dispensing station 132, a laminating station 133 and a discharging station 134 In order to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com