Cloth ironing machine for textile field

A technology for ironing machines and fabrics, applied in textiles and papermaking, fabric surface trimming, liquid injection devices, etc., can solve problems such as clogging, easy dirt residue outlets, insufficient water vapor pressure, etc., to prevent damage, prevent dirt residue outlets, Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

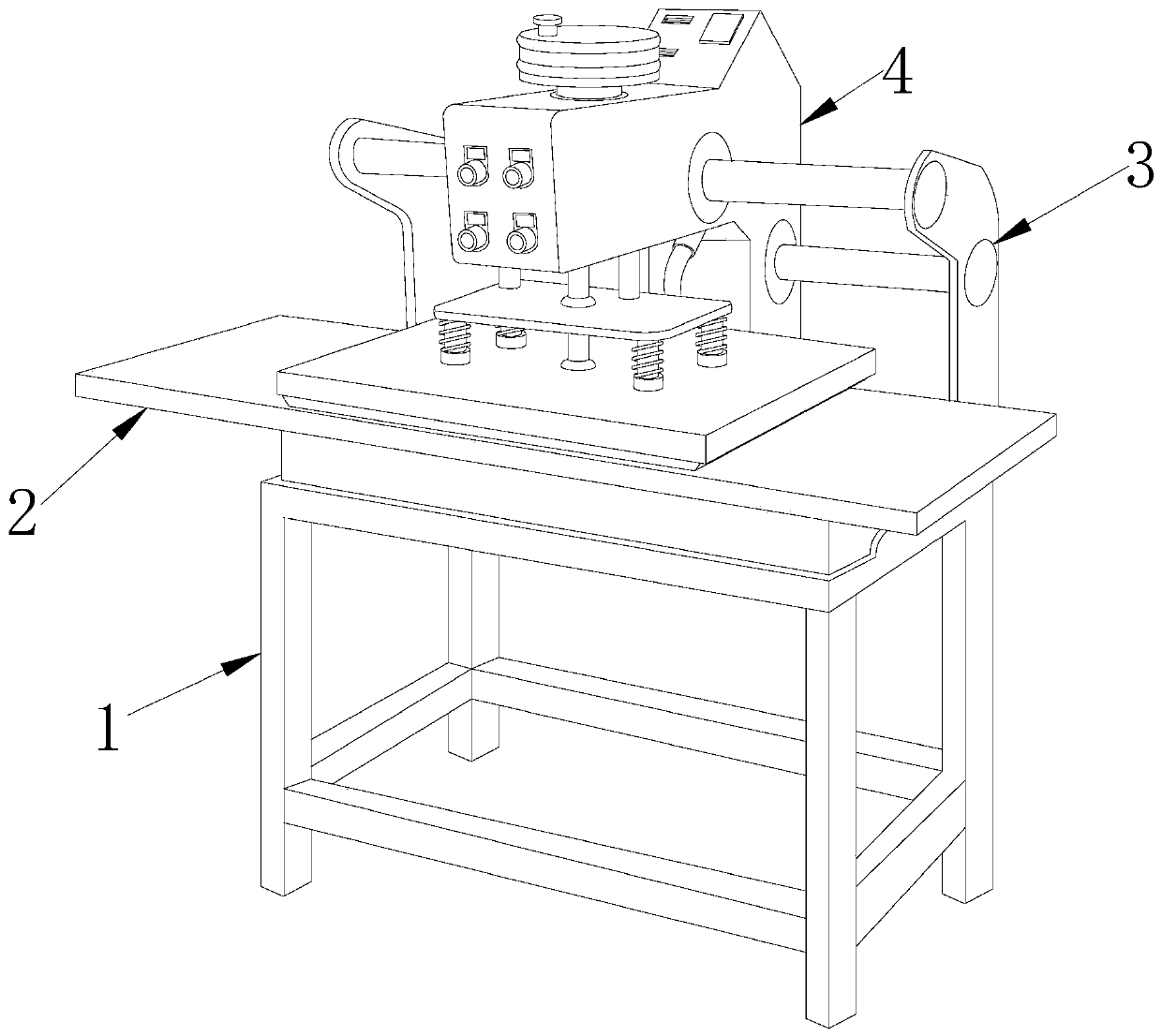

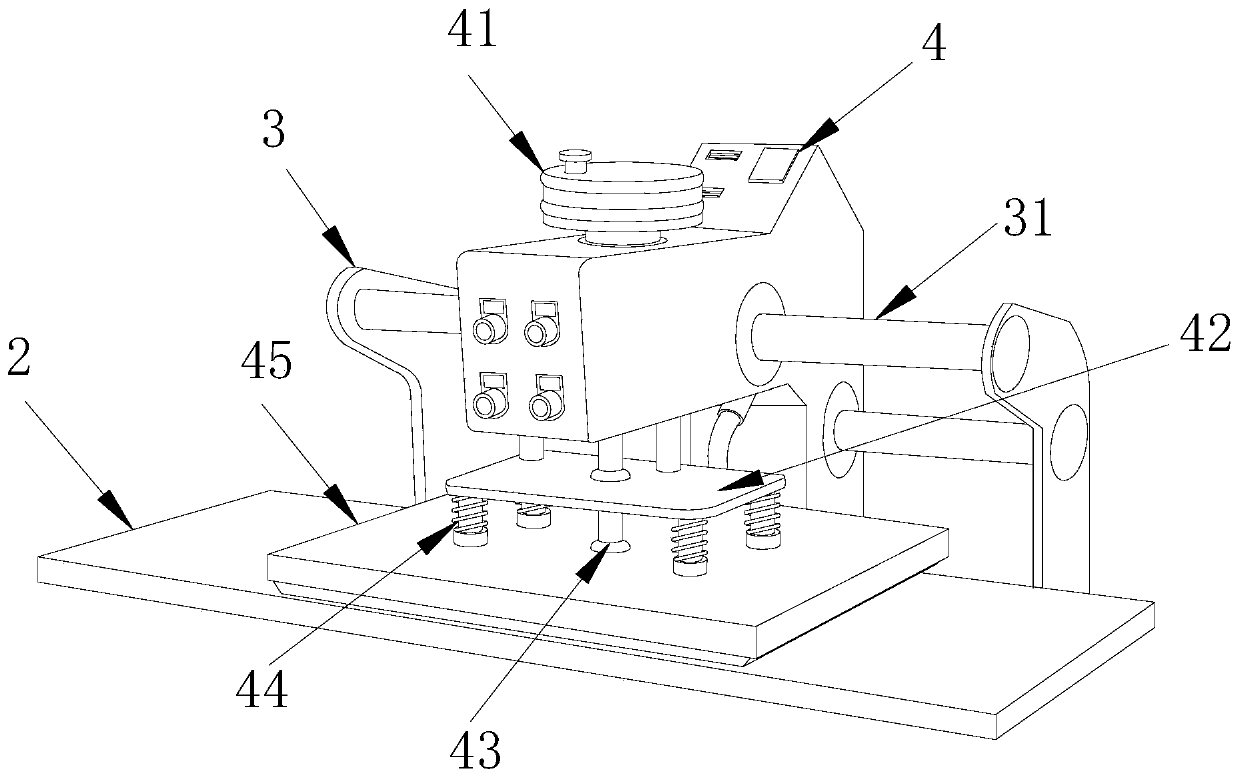

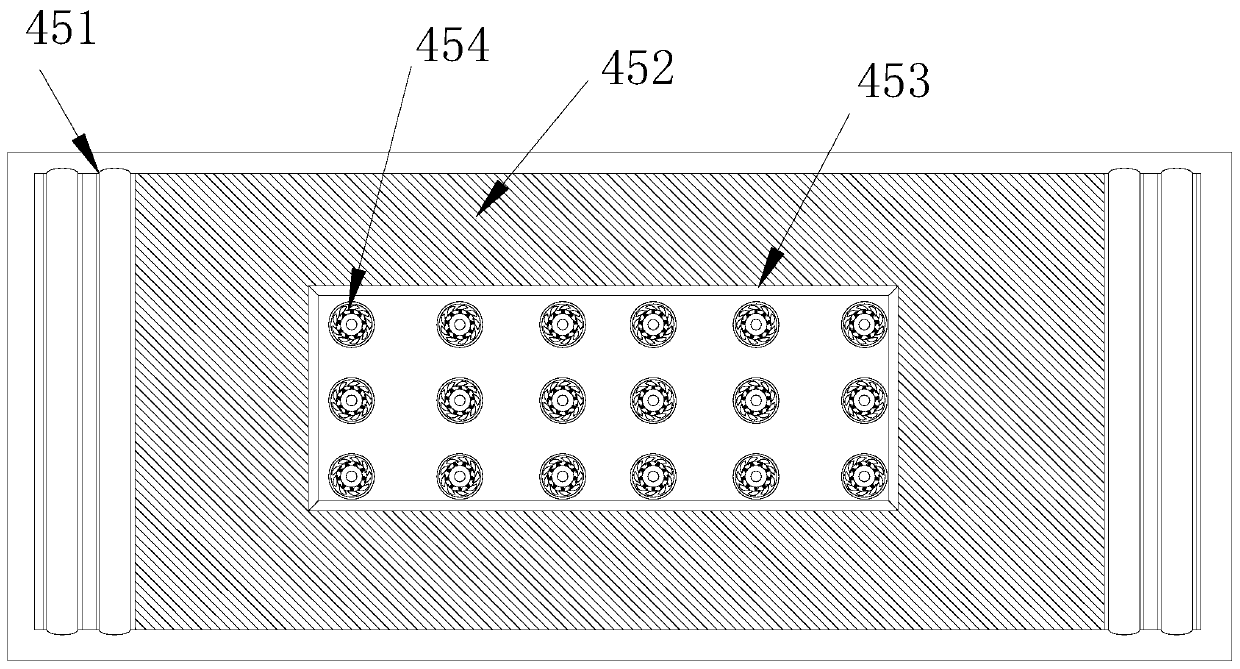

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a cloth ironing machine for the textile field, its structure includes a frame 1, a workbench 2, a moving frame 3, and a flattener 4, and the workbench 2 is fixed on the upper end of the frame 1, The moving frame 3 is welded and connected with the frame 1, the ironing device 4 is movably matched with the moving frame 3, and the ironing device 4 is provided with a water inlet 41, a movable plate 42, a water outlet pipe 43, and a telescopic rod 44 , ironing board 45, the water inlet 41 is connected with the ironing board 45 through the water outlet pipe 43, the movable board 42 is located at the upper end of the ironing board 45 and is connected by a telescopic rod 44 between them, and the ironing board 45 is connected with the working Table 2 is horizontally parallel, and the bottom surface of the ironing board 45 is a concave structure in a horizontal groove around the four sides. There are rollers 451,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com