Deep-water horizontal connector pressure cap

A technology of connectors and pressure caps, applied in wellbore/well components, sealing/package, earthwork drilling and production, etc., can solve the problems of difficult underwater installation, large pressurized space, limited operating space, etc., to solve the problem of overturning , improve reliability, and improve the efficiency of underwater installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

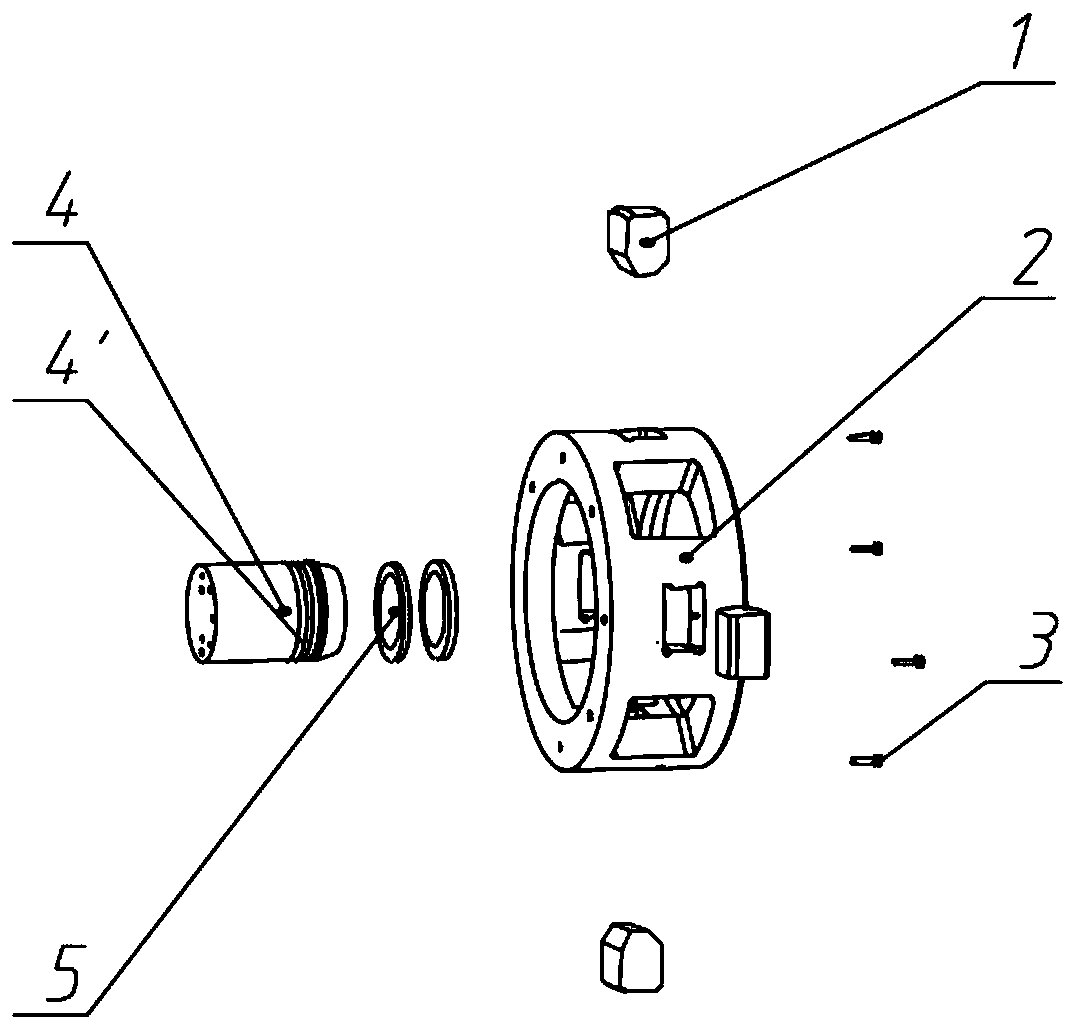

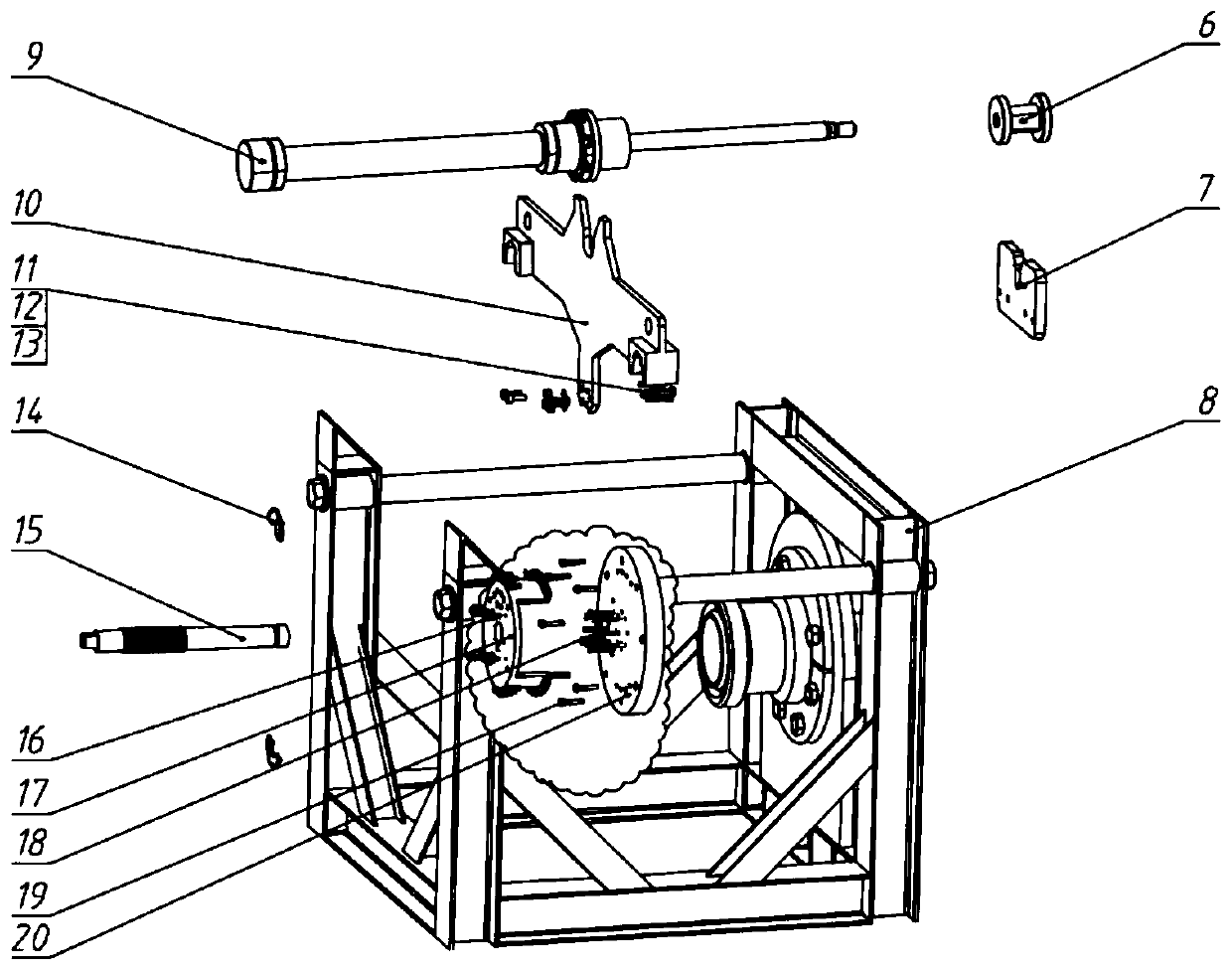

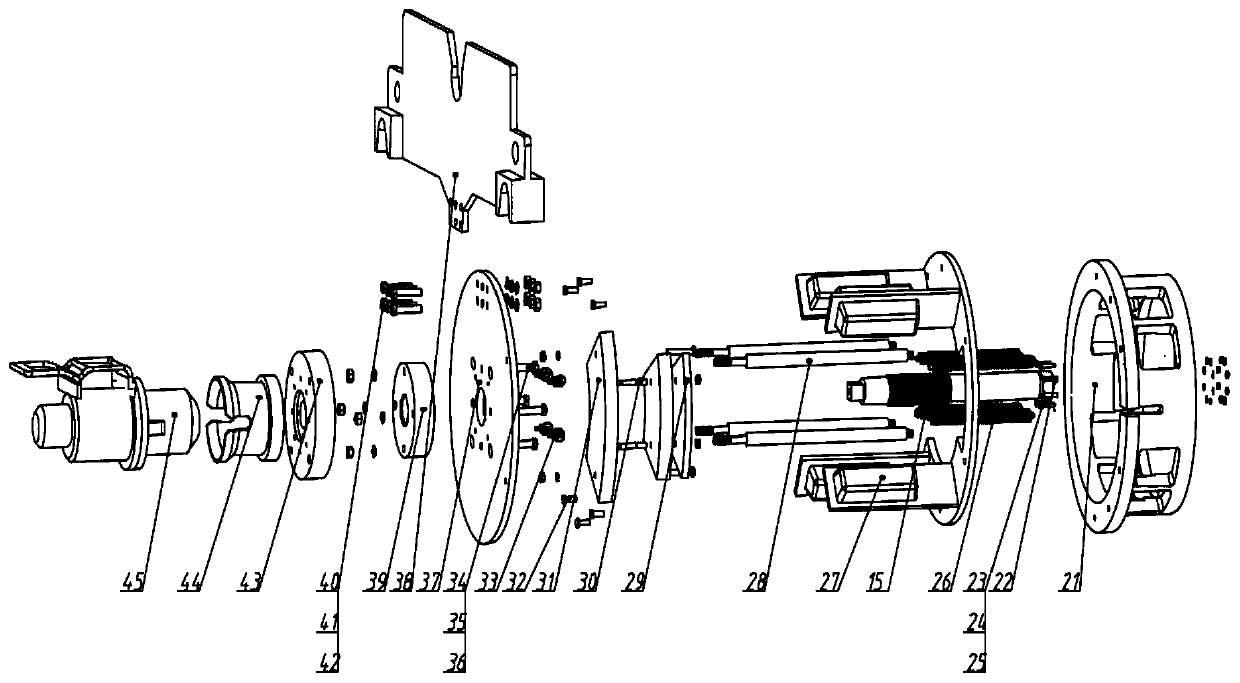

[0024] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the deep-water horizontal connector pressure cap of the present invention includes a sealing mechanism, and the sealing mechanism is mainly composed of four blocks 1, a wall tube 2, a sealing mandrel 4, two sealing rings 5 and four positioning screws 3 ;Including the drawing-in mechanism, the drawing-in mechanism is mainly composed of a front guide plate 10, a pull head 6, a support plate 7, a connecting cover 17, a pushing plate 20, two connecting semicircular plates 14 and a hydraulic cylinder 9; It also includes a feed mechanism, the feed mechanism is mainly composed of a rear guide plate 38, a drive ring 21, an ROV wrench base 44, an ROV wrench 45, a feed bolt 15, a feed nut 39, a packing pressure plate 48, A compression ring 47, a V-shaped packing seal 48, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com