Engine and vehicle with same

An engine and drive shaft technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of increased force, increased wear, knocking, etc., to improve the force, reduce wear, and reduce friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

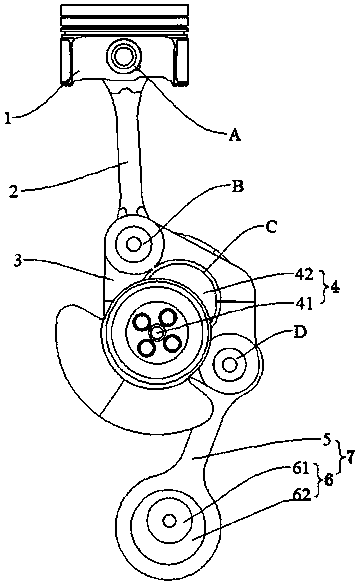

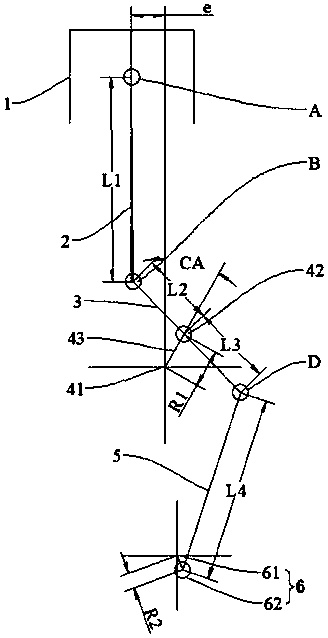

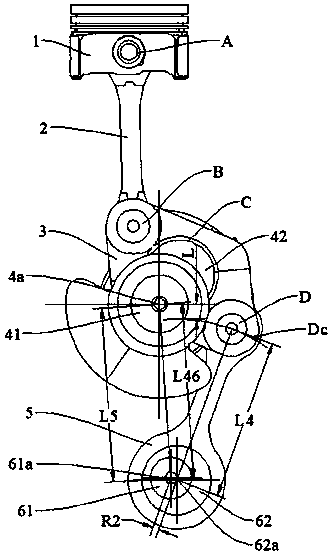

[0028] The following will refer to Figure 1-Figure 5 The engine of the present invention will be described in detail in conjunction with the embodiments.

[0029] refer to figure 1 As shown, the engine according to the embodiment of the present invention includes: a piston 1 , a connecting rod 2 , an adjustment element 3 , a crankshaft 4 and a compression ratio adjustment mechanism 7 .

[0030] Piston 1 can move in cylinder 8 of the engine, combined with figure 1 , Figure 4 As shown, the piston 1 can move along the cylinder bore of the cylinder 8 figure 1 up and down movement.

[0031] The main journal 41 of the crankshaft 4 is rotatably arranged on the cylinder block of the engine, and the connecting journal 42 of the crankshaft 4 is staggered from the central axis of the main journal 41 . There may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com