Variable compression ratio mechanism and engine

A compression ratio, engine block technology, applied in machine/engine, engine control, mechanical equipment, etc., can solve problems such as wear, impact on mechanism reliability, and large loss of connecting rod wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

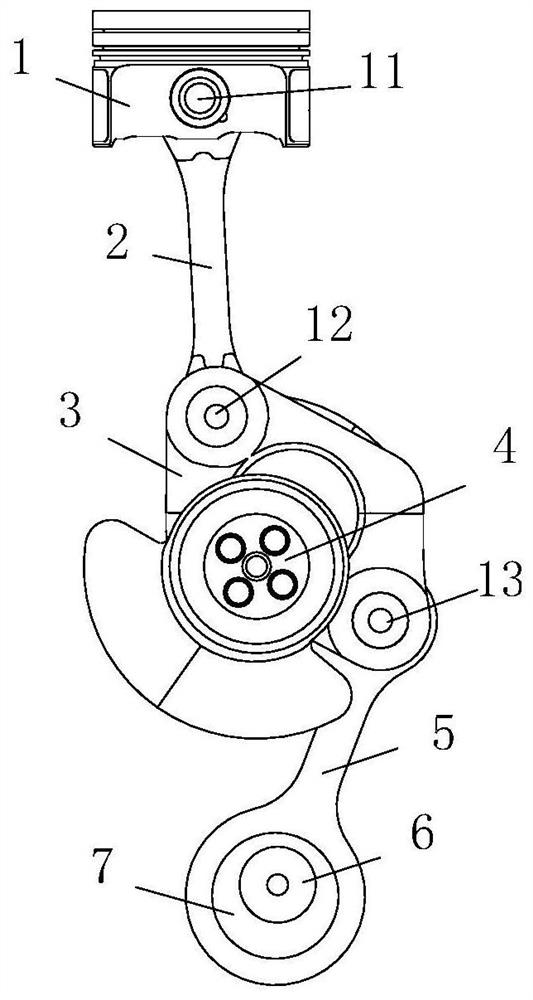

[0037] This embodiment relates to a variable compression ratio mechanism, which is a multi-link variable compression ratio mechanism, and as figure 1 As shown in , the mechanism includes a piston 1 slidingly arranged in an engine block not shown in the figure, rotating a crankshaft 4 arranged in the engine block and an eccentric shaft 6 with an eccentric wheel 7, and rotating a crankshaft 4 arranged in the engine block The adjusting connecting rod 3 on the crank pin in the middle, and the execution connecting rod 2 and the driving connecting rod 5 that are hinged to both ends of the adjusting connecting rod 3 and are hingedly connected to the piston 1 and the eccentric wheel 7 respectively.

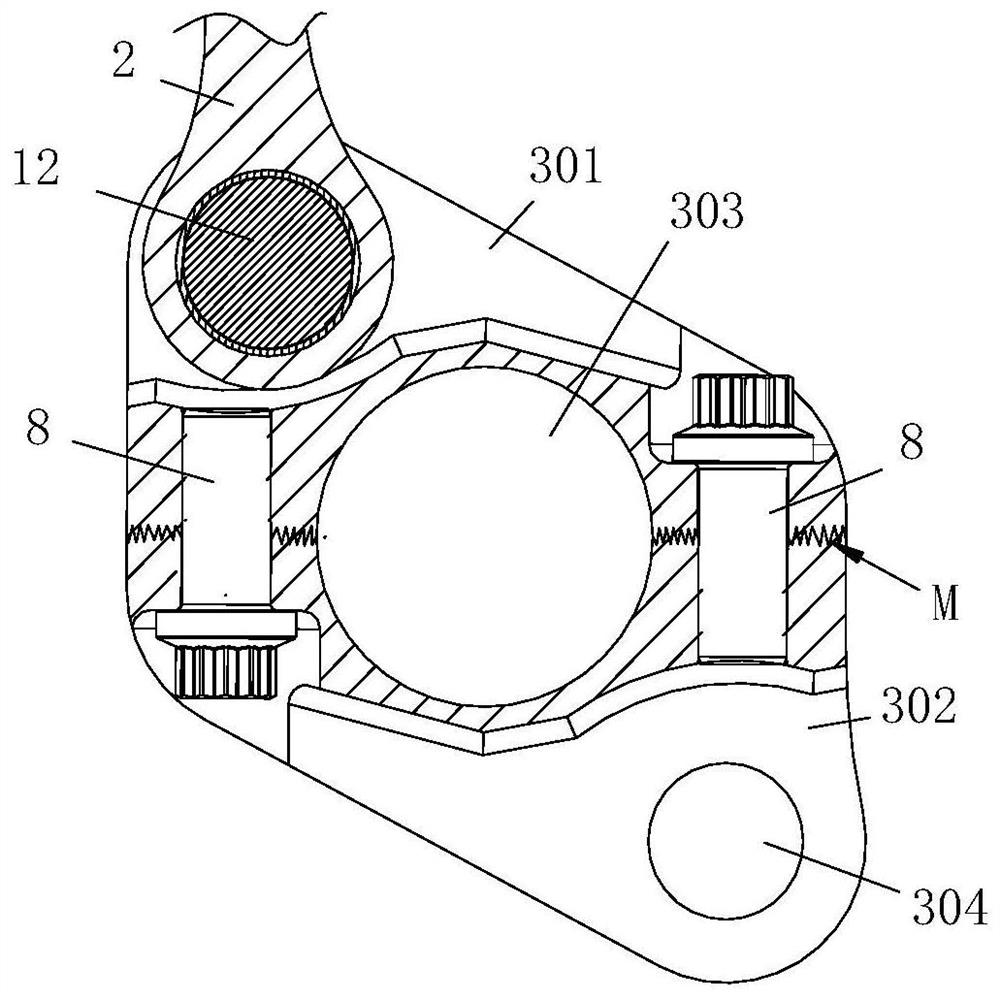

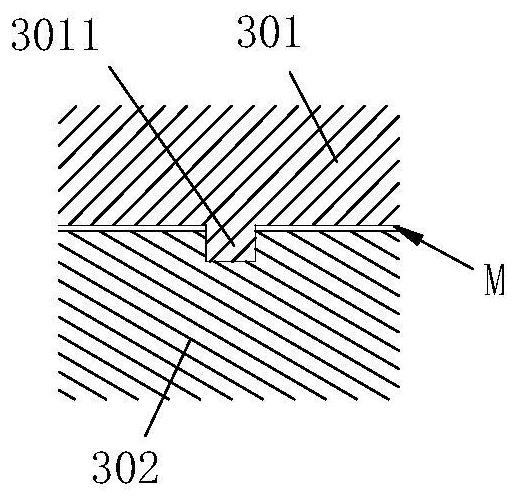

[0038] Wherein, the structure of the above-mentioned adjusting link 3 is further as figure 2 As shown in , it specifically includes an upper rod part 301 and a lower rod part 302 that are fixed together by a connecting piece 8. The structures of the upper rod part 301 and the lower rod p...

Embodiment 2

[0054] This embodiment relates to a variable compression ratio engine, which includes an engine block, and also includes a variable compression ratio mechanism as in Embodiment 1 arranged in the engine block. The engine of this embodiment adopts the variable compression ratio mechanism in the first embodiment, which can reduce the wear of the actuator connecting rod 2 and the driving connecting rod 5, and can improve the service life of the two connecting rod structures, thus having good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com