A performance testing device for low-dimensional optoelectronic materials

A technology for optoelectronic materials and testing devices, which is used in measuring devices, material analysis by optical means, and material analysis, etc., which can solve problems such as inaccurate results and changes in the area where the light intensity cannot be illuminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

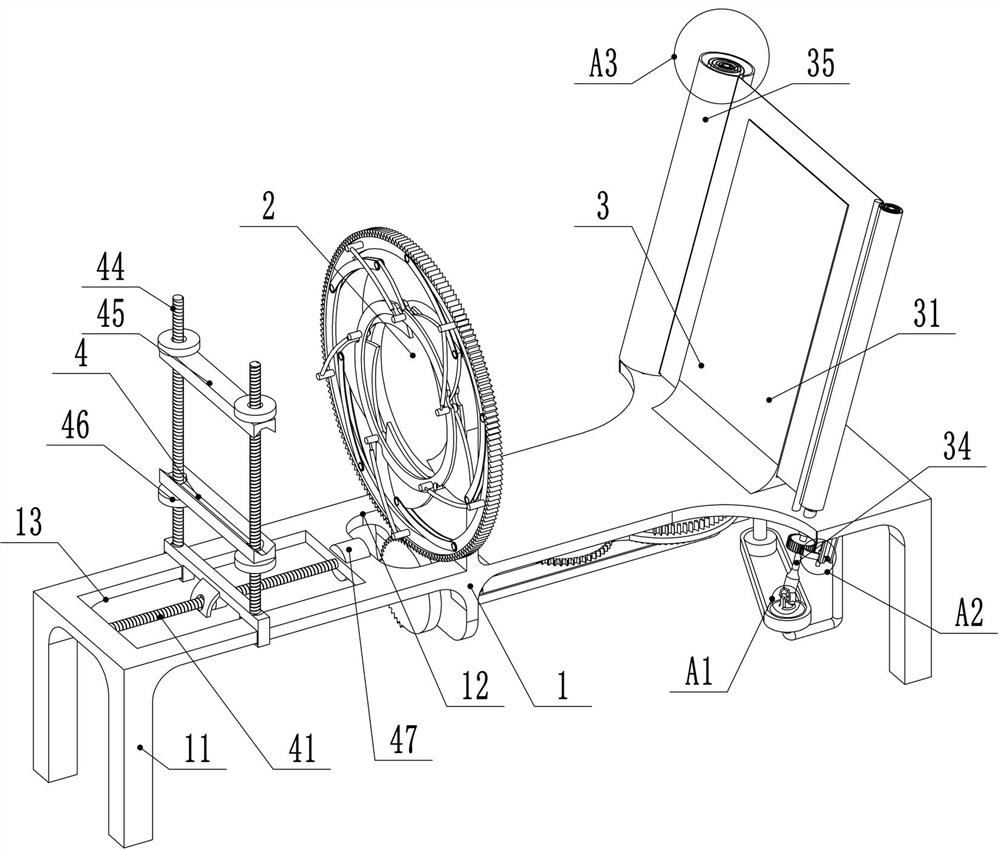

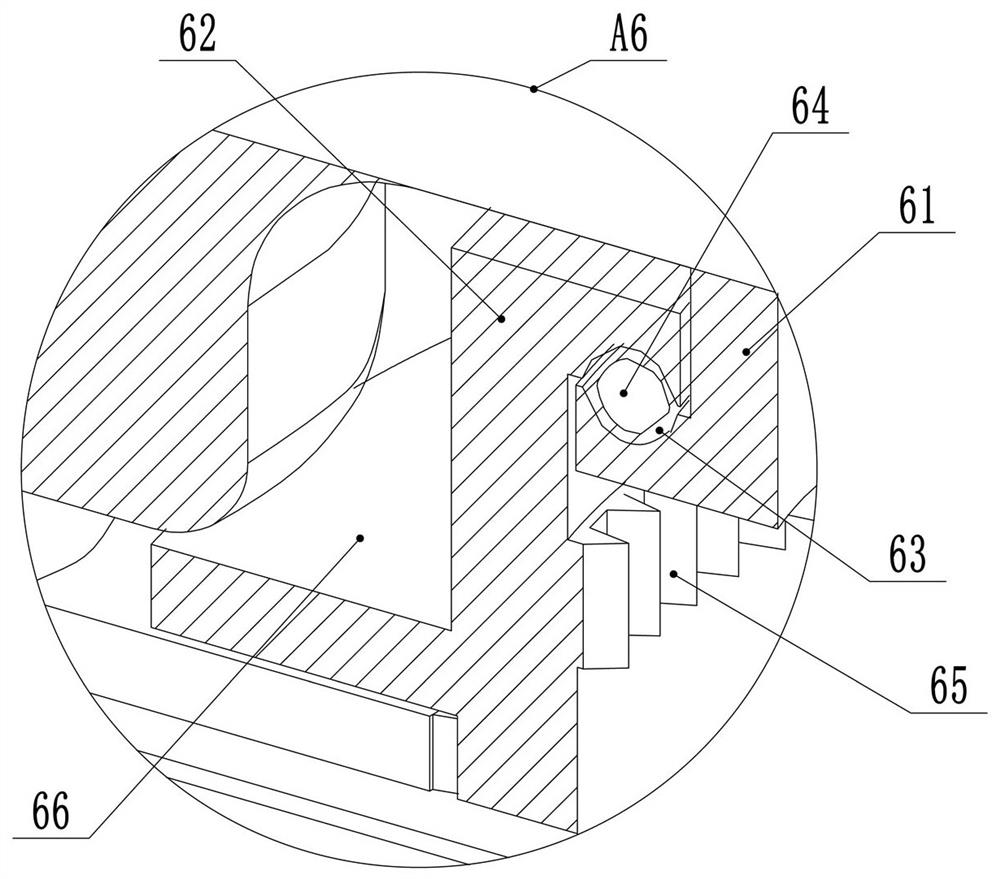

[0042] Embodiment 1, the present invention is a performance testing device for low-dimensional photoelectric materials, including a bracket 1, a light-concentrating structure 2 is installed in the middle of the bracket 1, a light-reflecting structure 3 is installed at one end of the bracket 1, and the other end of the bracket 1 The fixed structure 4 of the device to be detected is installed, and the bottom end of the bracket 1 is equipped with a power structure 5. The power structure 5 is connected to the first transmission structure 6, and the first transmission structure 6 is respectively connected to the light-concentrating structure 2 and the light-reflecting structure 3 through the transfer transmission structure. connection, the transfer transmission structure includes a second transmission structure 7 and a third transmission structure 8, the first transmission structure 6 is connected to the reflective structure 3 through the second transmission structure 7, and the firs...

Embodiment 2

[0043] Embodiment 2. On the basis of Embodiment 1, the light-concentrating structure 2 includes an inner ring 21 and an outer gear ring 26. The inner ring 21 is installed on the surface of the bracket 1. A convex lens 22 is installed inside one side of the inner ring 21. The inner ring 21 The other side of 21 is provided with a chute 23 inside, and the inside of the chute 23 is rotatably connected with a baffle plate 24. The side of the baffle plate 24 is connected with the outer gear ring 26 through an arc-shaped connecting plate 25, and the connection between the outer gear ring 26 and the inner ring 21 There is also a piston tube 27 connected between them, the external gear ring 26 is meshed with a toggle gear 89, an opening 12 is opened at the position corresponding to the toggle gear 89 on the bracket 1, and the toggle gear 89 is set to 1 / 2 teeth. The structural setting of the shaped connecting plate 25 makes the position of the rear baffle plate 24 change when the toggle ...

Embodiment 3

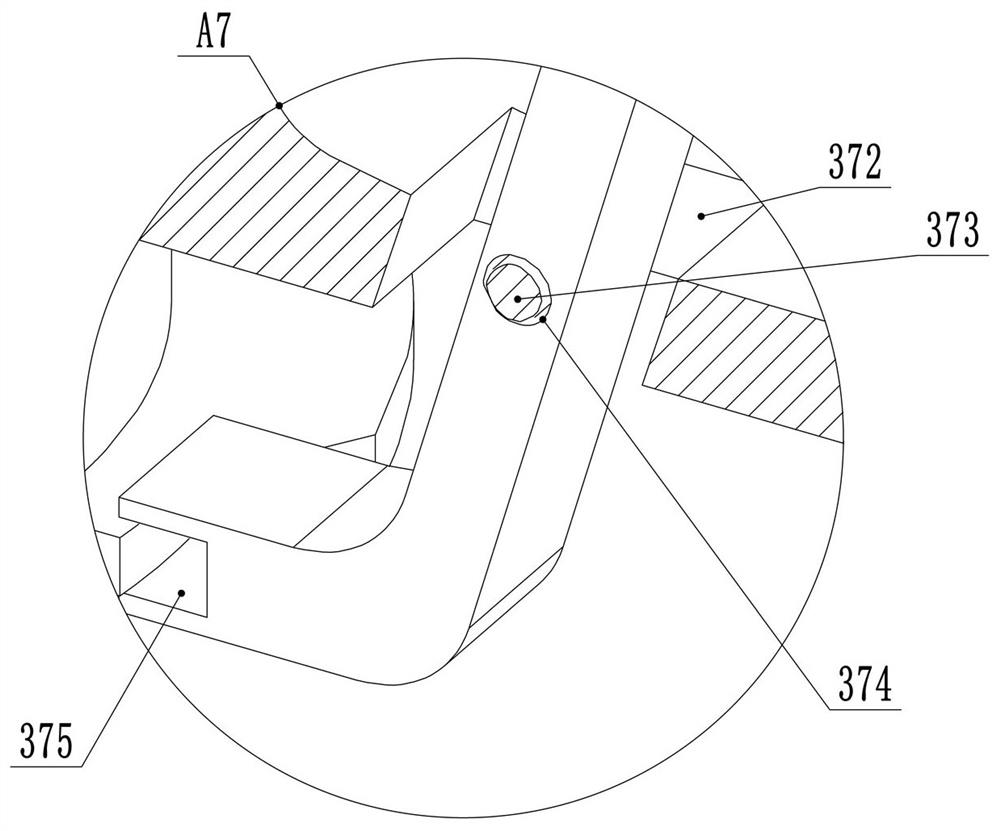

[0044] Embodiment 3, on the basis of Embodiment 1, the reflective structure 3 includes a high-transparency glass plate 31 obliquely installed on the surface of the bracket 1, the reflective area of the high-transparency glass plate 31 is larger than the light-transmitting area of the light-condensing structure 2, and the high-transparency The inside of the glass plate 31 is provided with a slide groove 32, the inside of the slide groove 32 is slidably connected with a reflective film 33, one end of the reflective film 33 is connected with a reflective film collecting shaft 34, and the other end of the reflective film 33 is connected with a reflective film installation pipe 35. The pressing frame 36 that presses the reflective film 33 is installed on the surface of the transparent glass plate 31 far away from the concentrating structure 2, and a pressing plate 37 is installed at the position corresponding to the pressing frame 36 on the support 1; the pressing frame 36 is pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com