A multifunctional blast furnace harmful element adsorption experiment method and device

The technology of a harmful element and an experimental method is applied in the field of a multifunctional blast furnace harmful element adsorption experimental method and its device, which can solve the problems such as the introduction of external influences by liquid and other elements, the single type of harmful element raw materials, and the large difference in the types of harmful elements. Achieve the effect of reducing the cost of blast furnace production experiments, improving applicability and predictability, and improving stability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

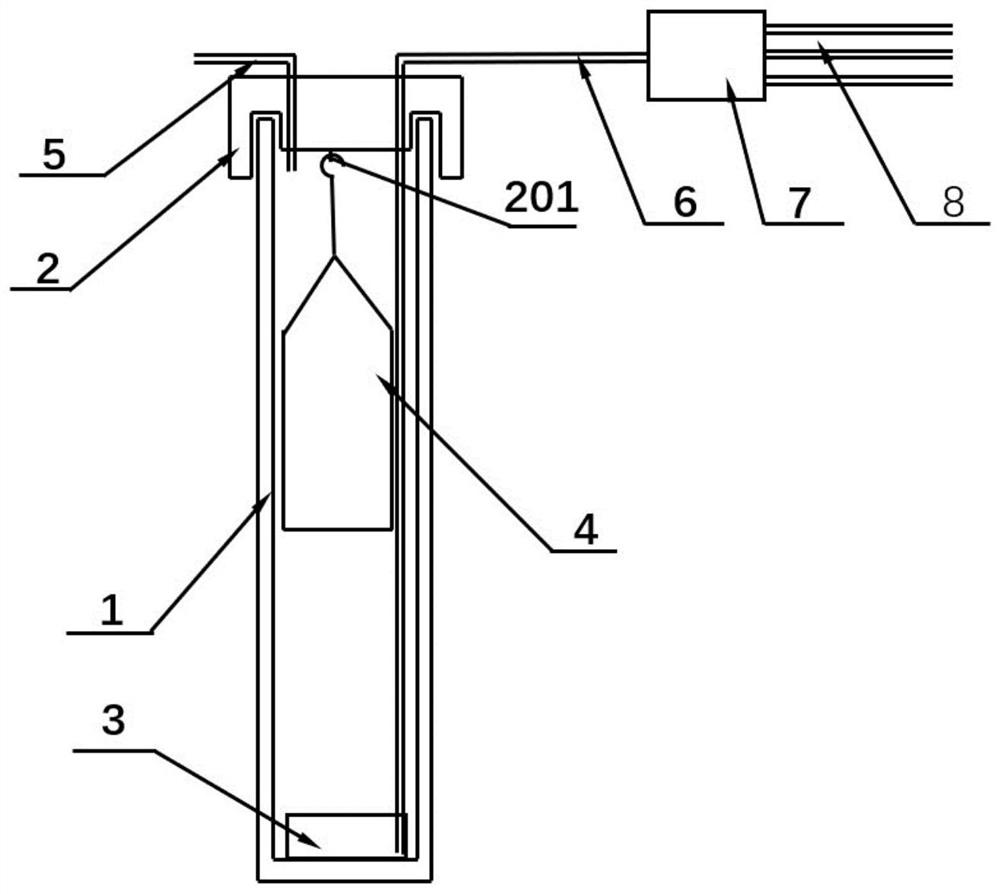

[0077] A multifunctional blast furnace harmful element adsorption experiment method comprises the following steps:

[0078] S1. Add 10g of zinc particles to the upper support frame of the harmful element steam generating device, and then place the harmful element steam generating device on the bottom of the reaction tube. The harmful element steam generating device is located in the lower heating element area of the two-stage heating furnace;

[0079] S2, placing the reaction tube vertically in a two-stage heating furnace;

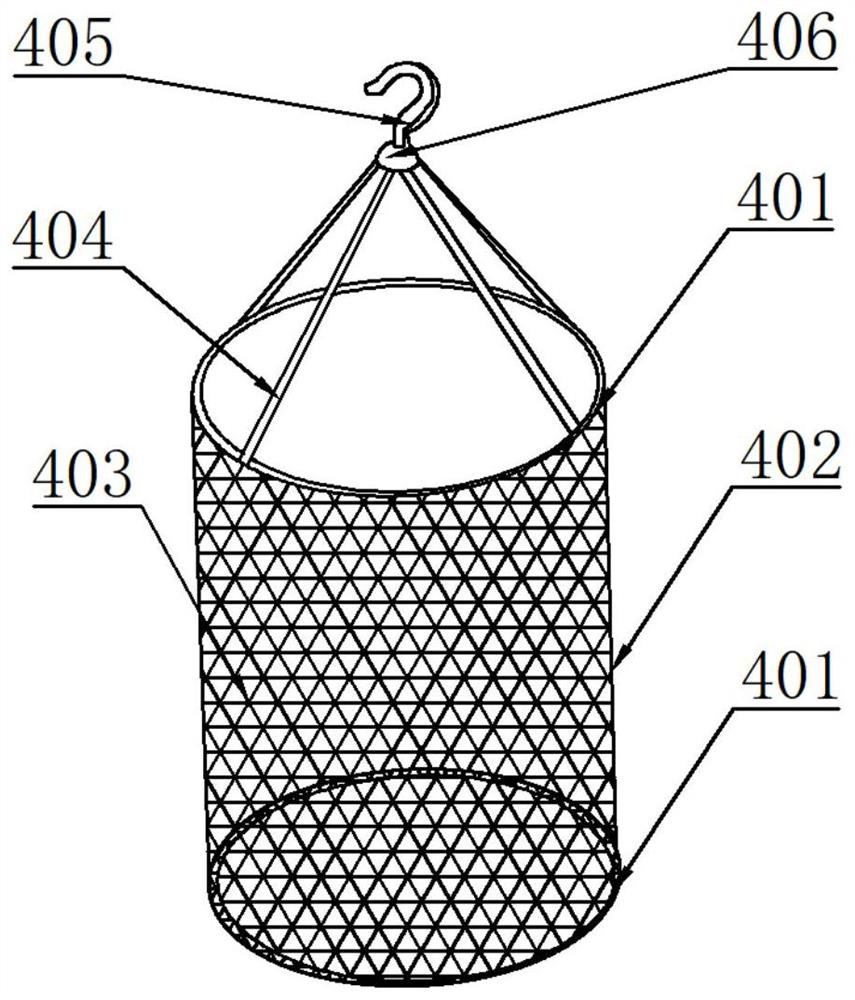

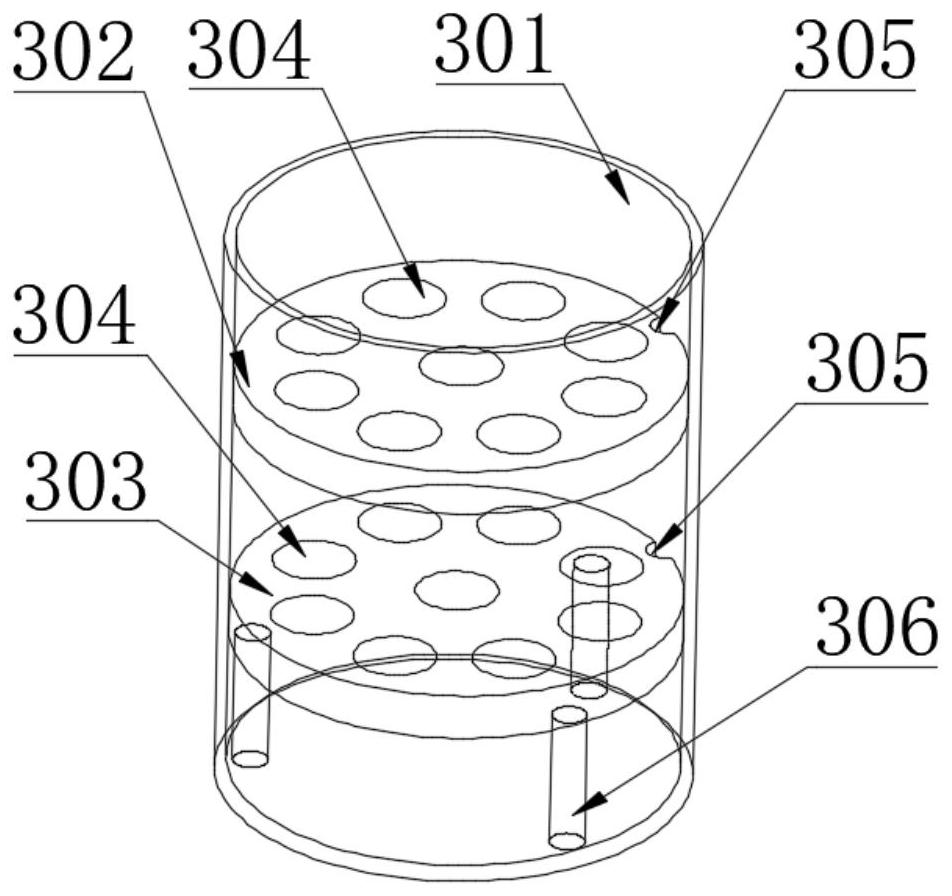

[0080] S3. Mix 100g of pellets, 100g of sintered ore and 100g of coke evenly and add them into the mesh cylinder cavity of the harmful element adsorption device, and hang the hook on the ring of the sealing cover, so that the harmful element adsorption device is located in two sections The upper heating body area of the type heating furnace;

[0081] S4. Set the temperature rise mode of the two-stage heating furnace, set the preheating temperature of ...

Embodiment 2

[0105] This embodiment provides a multifunctional blast furnace harmful element adsorption experiment method, which is basically the same as in Example 1, except that the harmful element added in step S1 is potassium carbonate, and in step S3, 100g pellets, 100g Sinter and 100g of coke are sequentially added to the mesh cylinder cavity of the harmful element adsorption device; at the same time, in step S1, according to the chemical reaction formula K 2 CO 3 +2C=1.5 times of the calculated value of the stoichiometric ratio in 3CO+2K Add carbon elemental substance to reduce potassium carbonate to potassium elemental substance, and the heat preservation temperature in the area of the harmful element generating device is 1300°C; except for the above differences, other operations are the same , which will not be repeated here.

[0106] Figure 10 Middle (a) is the macro-morphological characterization diagram of pellets after potassium adsorption. From the results in the figure,...

Embodiment 3

[0111] This embodiment provides a multifunctional blast furnace harmful element adsorption experiment method, which is basically the same as in Example 1, except that the harmful element added in step S1 is sodium carbonate, and in step S3, 100g pellets, 100g Sintered ore and 100g coke are sequentially added to the mesh cylinder cavity of the harmful element adsorption device; at the same time, in step S1, according to the chemical reaction formula Na 2 CO 3 1.5 times of the stoichiometric ratio calculation value of +2C=3CO+2Na adds carbon simple substance and sodium carbonate is reduced to sodium simple substance, and the insulation temperature of described harmful element generation device area is 1300 ℃; Except above-mentioned difference, other operations are all the same, I won't repeat them here.

[0112] Figure 12 Middle (a) is the macroscopic characterization result diagram of the pellets after adsorbing sodium element. It can be seen from the figure that a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com