Aluminium oxide silicide carrier

An alumina carrier, silicified alumina technology, applied in the directions of aluminum silicate, silicon compound, silicate, etc., can solve the problems of increased production experiment cost, increased experimental equipment investment, difficulty in single-chromatographic column separation, etc. The effect of sample resolution, reduced experimental cost, and shortened analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

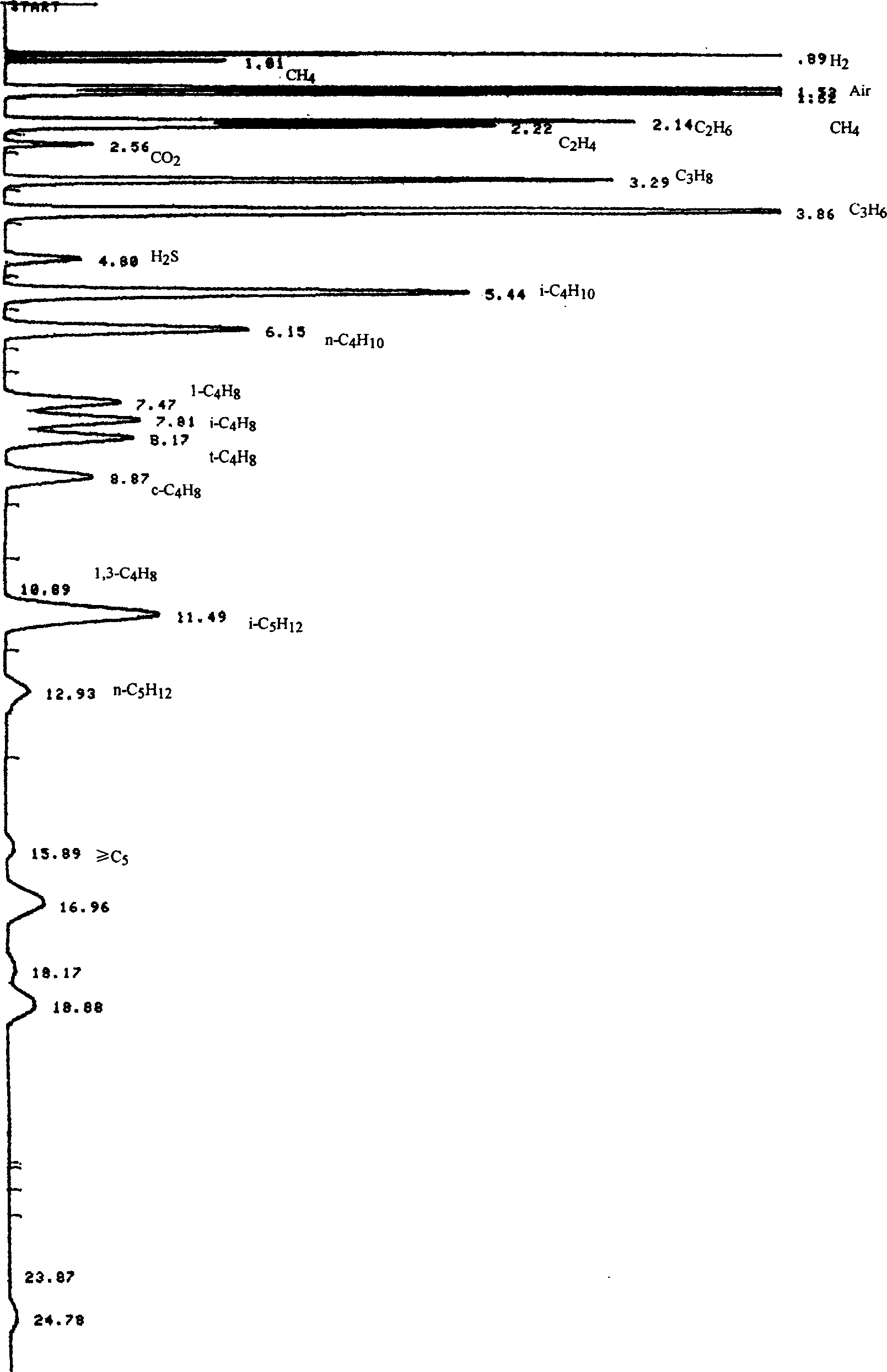

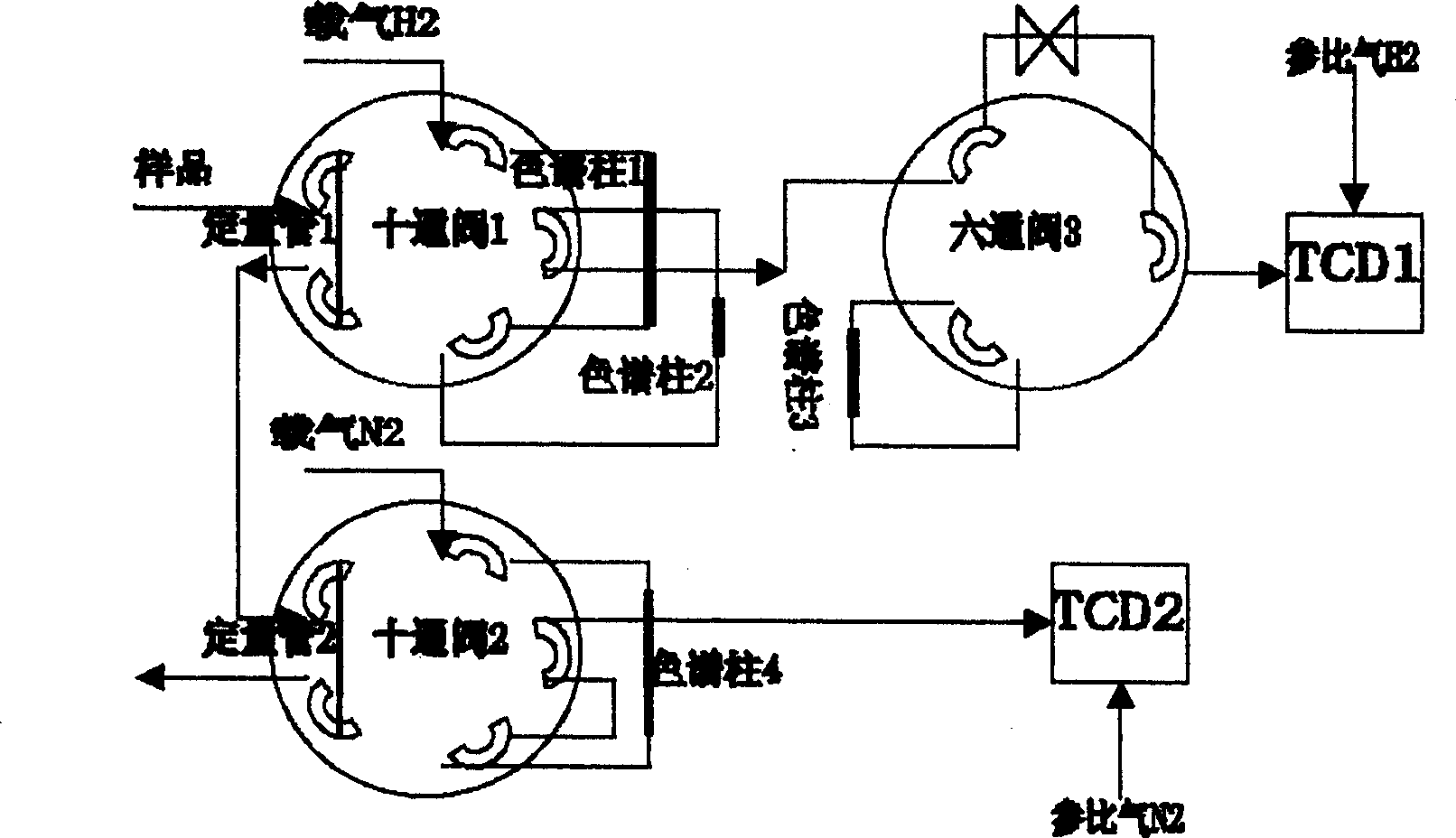

[0010] The present invention consists of Al 2 o 3 The raw material reacts with the silicon-containing raw material at high temperature for several hours (2-10 hours) to produce silicided alumina. Examples of its application to refinery gas samples are as follows:

[0011] Refinery Gas Type

main ingredient

carbon dioxide, oxygen, nitrogen, carbon monoxide, hydrocarbons

air, hydrogen sulfide, hydrocarbons

Liquefied gas

Ethane, ethylene, propane, propylene, isobutane, n-butane, butene, a small amount of carbon five to

carbon six components

dry gas, rich gas

Hydrogen, air, carbon monoxide, carbon dioxide, hydrogen sulfide, methane, ethane, ethylene,

Propane, propylene, carbon four, a small amount of carbon five to carbon six components

Hydrofining and heavy

Hydrogen, carbon dioxide, methane, ethane, propane, propylene, isobutane, hydrogen sulfide,

n-butane, a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com