Multi-sensor fusion measurement water cut and/or salinity measurement system

A technology of multi-sensor fusion and measurement system, which is applied in the field of dynamic testing of oil wells in the petroleum industry, to achieve the effects of saving costs, reducing treatment emissions, and improving dynamic control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment one: moisture content measuring system:

[0067] That is, the method for multi-sensor fusion measurement of water content is characterized in that,

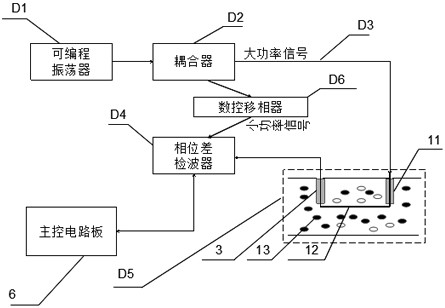

[0068] The multi-sensor fusion measurement water content and / or salinity measurement system is characterized in that the output of the programmable oscillator X1 is connected to the demultiplexer X2, the demultiplexer X2 is connected to the coupler X5 by communication, and the coupler X5 is connected by communication Digitally controlled phase shifter X6, digitally controlled phase shifter X6 communication connection phase difference detector X7;

[0069] The output of the programmable oscillator X1 is connected to the multi-channel signal distributor X2 to generate multiple high-frequency signals with the same frequency, same amplitude and same phase;

[0070] First, one of the high-frequency signals is taken into the coupler X5, and two signals are output. The signal with higher power enters directly from one...

Embodiment 2

[0072] Embodiment two: as a further improved scheme or parallel scheme, the method for salinity determination;

[0073] That is, the method for multi-sensor fusion determination of salinity is characterized in that,

[0074] The output of the programmable oscillator X1 is connected to the multi-channel signal distributor X2 to generate multiple high-frequency signals with the same frequency, same amplitude and same phase;

[0075] Take two high-frequency signals, one of which is directly entered by one end of the salinity guided wave transmission line X18 of the double waveguide resonator X15, and the other end is output to the amplitude difference detector X3, the two high-frequency signals Another high-frequency signal directly enters the amplitude difference detector X3, and the salinity is obtained by measuring the amplitude difference of the two signals, which is the salinity measurement part.

[0076] It should be noted that the salinity determination provided above is ...

Embodiment 3

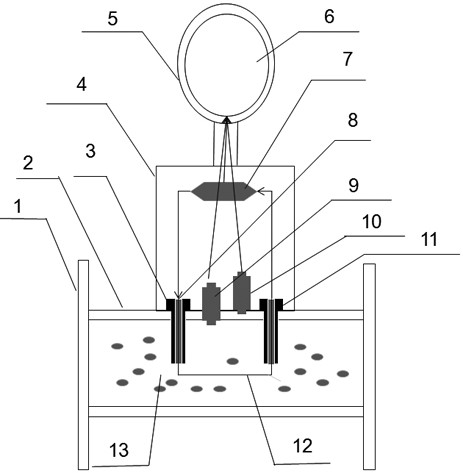

[0077] Embodiment 3, as a further improvement scheme or parallel scheme, the composition of the double waveguide resonator X15 as a whole is based on Embodiment 1 and Embodiment 2,

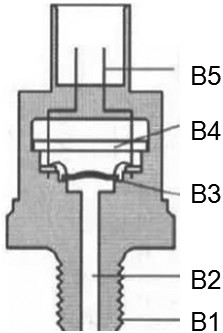

[0078] The water content measurement part and the salinity measurement part constitute the double waveguide resonant cavity X15, the double waveguide resonant cavity X15 includes a metal shell X14, and the metal shell X14 includes a water-containing guided wave transmission line support X8, a salinity guided wave transmission line Bracket 1 X9, salinity guided wave transmission line bracket 2 X10, water-containing guided wave transmission line bracket 2 X11; water-containing guided-wave transmission line bracket 1 X8 and water-containing guided-wave transmission line bracket 2 X11 form a water-containing guided-wave transmission line bracket; Wave transmission line bracket one X9 and salinity guided wave transmission line bracket two X10 constitute the salinity guided wave transmission line bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com