Small digging and harvesting device

A technology of harvesting device and digging device, which is applied in the direction of digging harvesters, harvesters, and rigid working parts, etc., can solve the problems of cost increase, failure to collect radish, radish collection, etc., so as to improve the service life of the machine and reduce manual labor Quantity, production and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

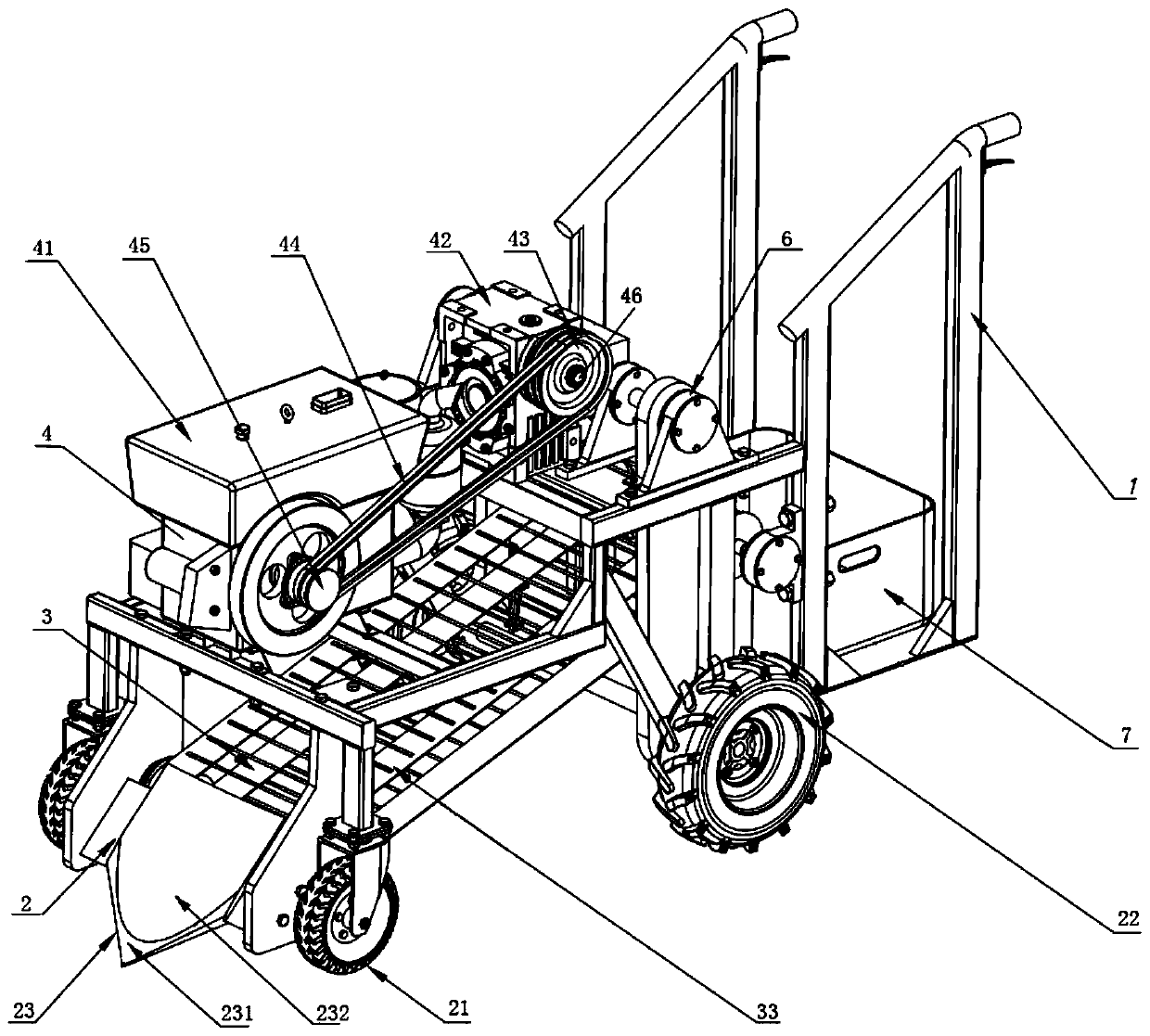

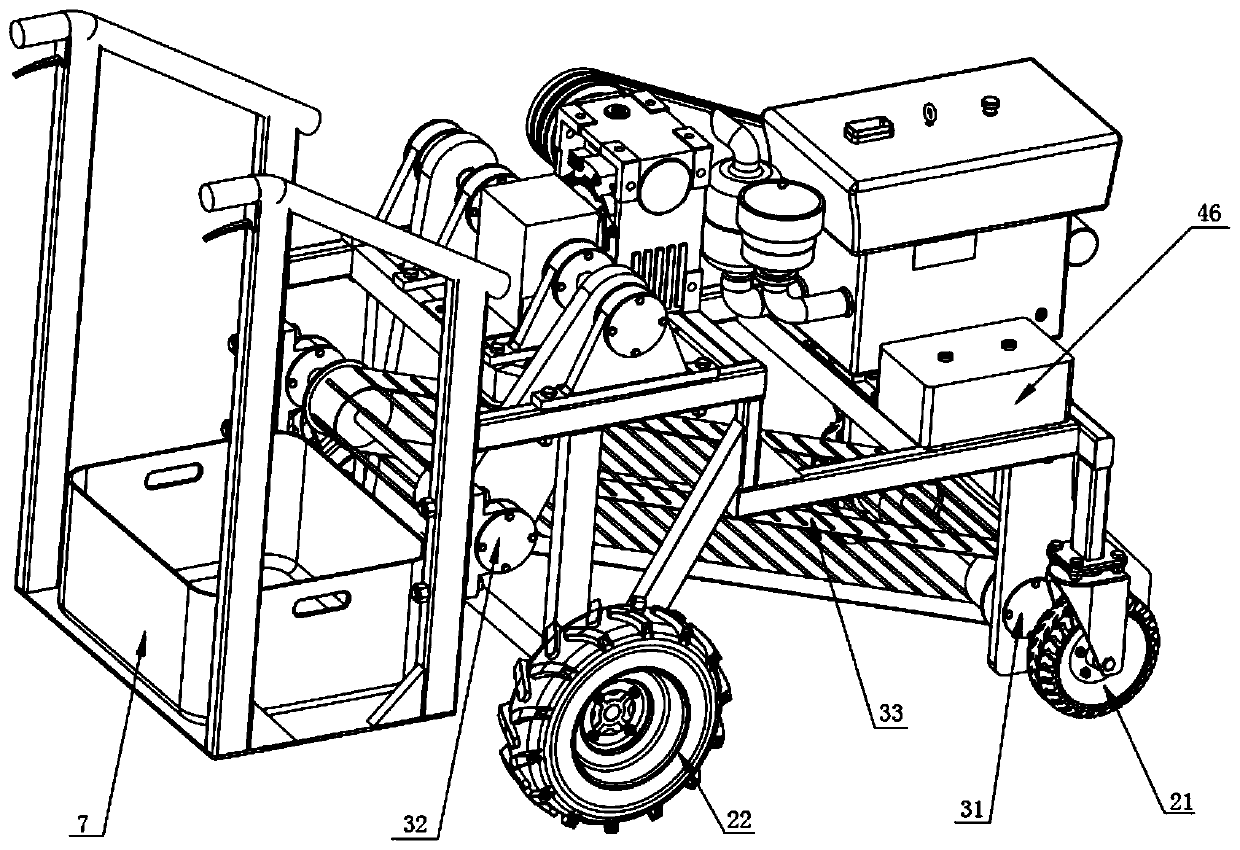

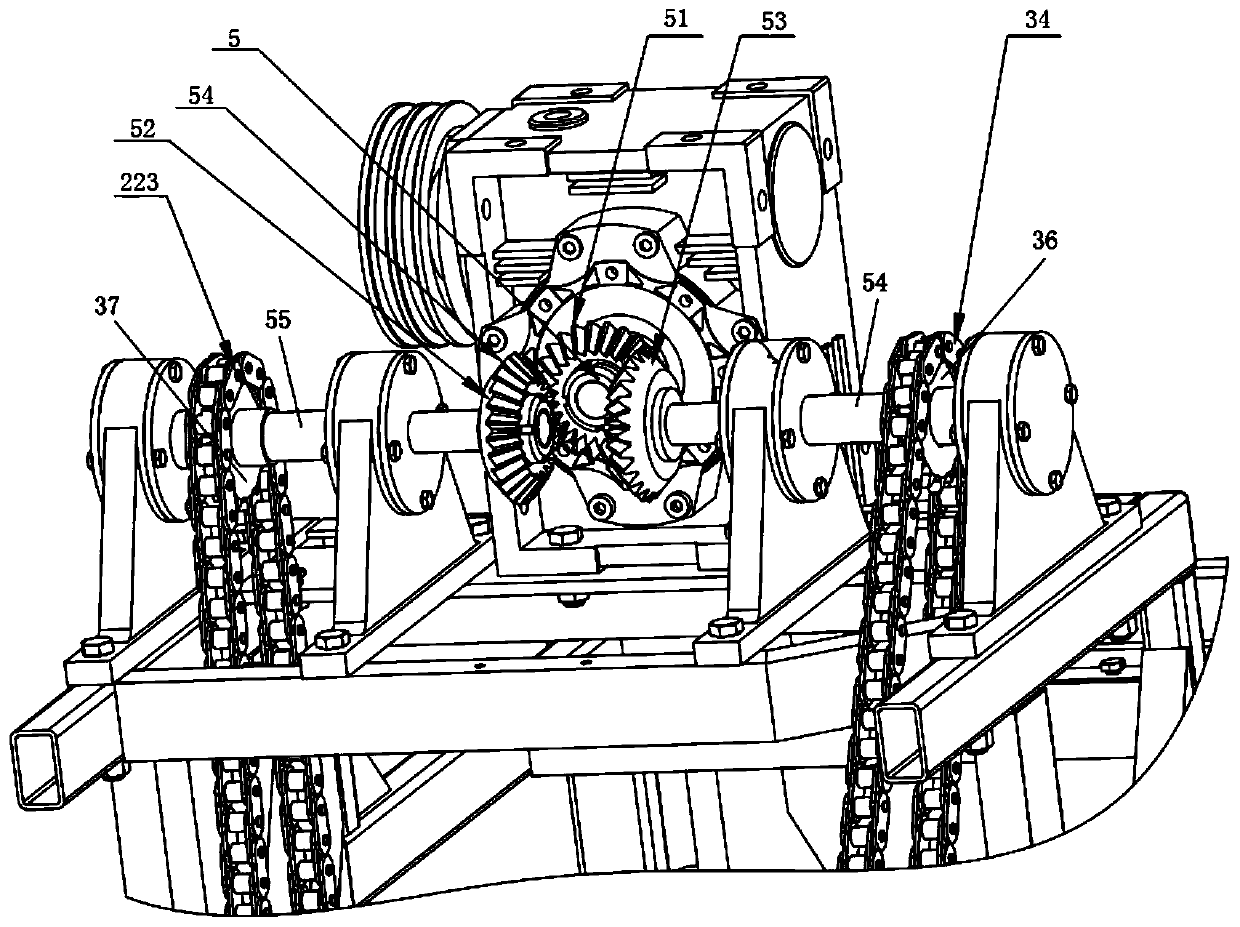

[0026] like Figure 1-8 As shown, the present invention provides a technical solution: a small excavation and harvesting device, including a frame 1, an excavation device 2, a collection device 3, a power unit 4, a gear device 5, a dust cover 6, and a collection basket 7, wherein: Digging device 2, collecting device 3, power unit 4, gear device 5, dust cover 6, are all arranged on the frame 1, and digging device 2 is used for digging radish, and collecting device 3 is used for collecting the radish after being excavated, power The device 4 can provide power for the excavating device 2 and the collecting device 3 , and the gear device 5 is used as a switching device for starti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap