Telescopic fixture equipment rack for mechanical part machining

A technology of mechanical components and equipment racks, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as heavy equipment and complex structure of auxiliary tools, and achieve the effect of improving quality requirements and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

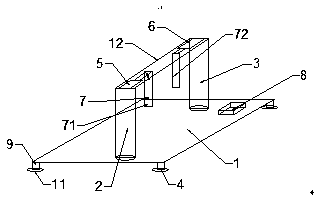

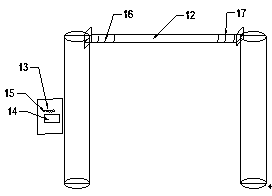

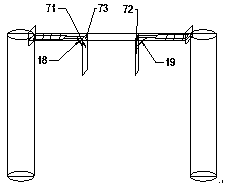

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as Figure 1 to Figure 3 As shown, the present invention is a telescopic fixture equipment frame for processing mechanical parts, including a support base 1, a first column 2, a second column 3, a suction support foot 4, a first telescopic machine 5, a second telescopic machine 6 and a fixture Component 7, the fixture component 7 includes a fixture plate 1 71, a fixture plate 2 72 and a pressure control detector 73, and the upper side surface of the support base 1 is symmetrically fixedly connected with the first column 2 and the second column 3 , the surface of the other side of the upper part of the support base 1 is screw-connected with a tool maintenance box 8, the bottom surface of the support base 1 is respectively fixedly connected with a support rod 9, and the bottom end of the support rod 9 is threadedly connected with a suction rubber sheath 11, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap