a coil assembly

A coil component, No. 1 technology, applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of enameled wire scratches, enameled wire deformation, and high strength of drawstrings, so as to reduce the pulling strength and use The effect is affected, the effect that improves the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

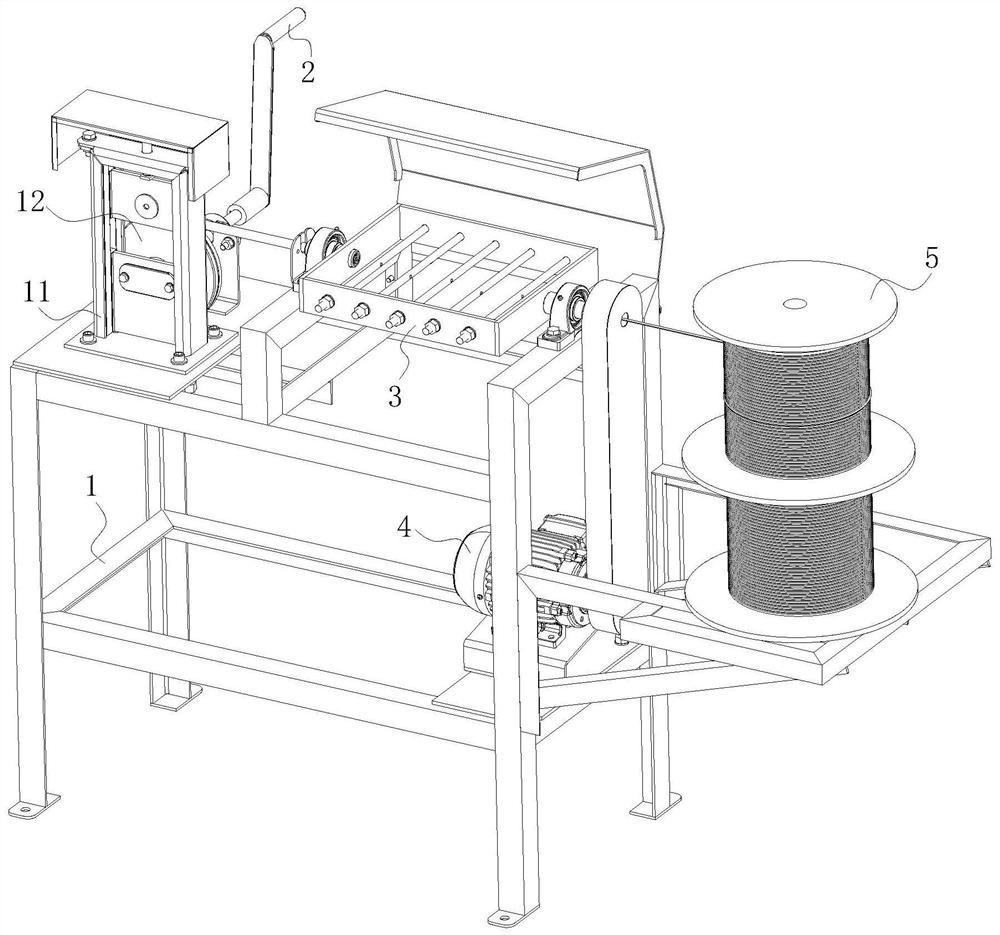

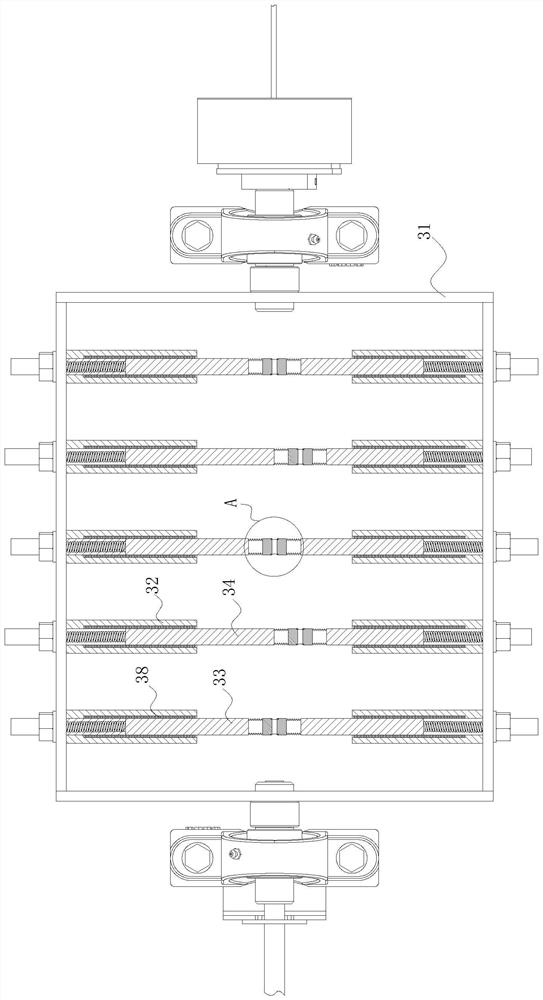

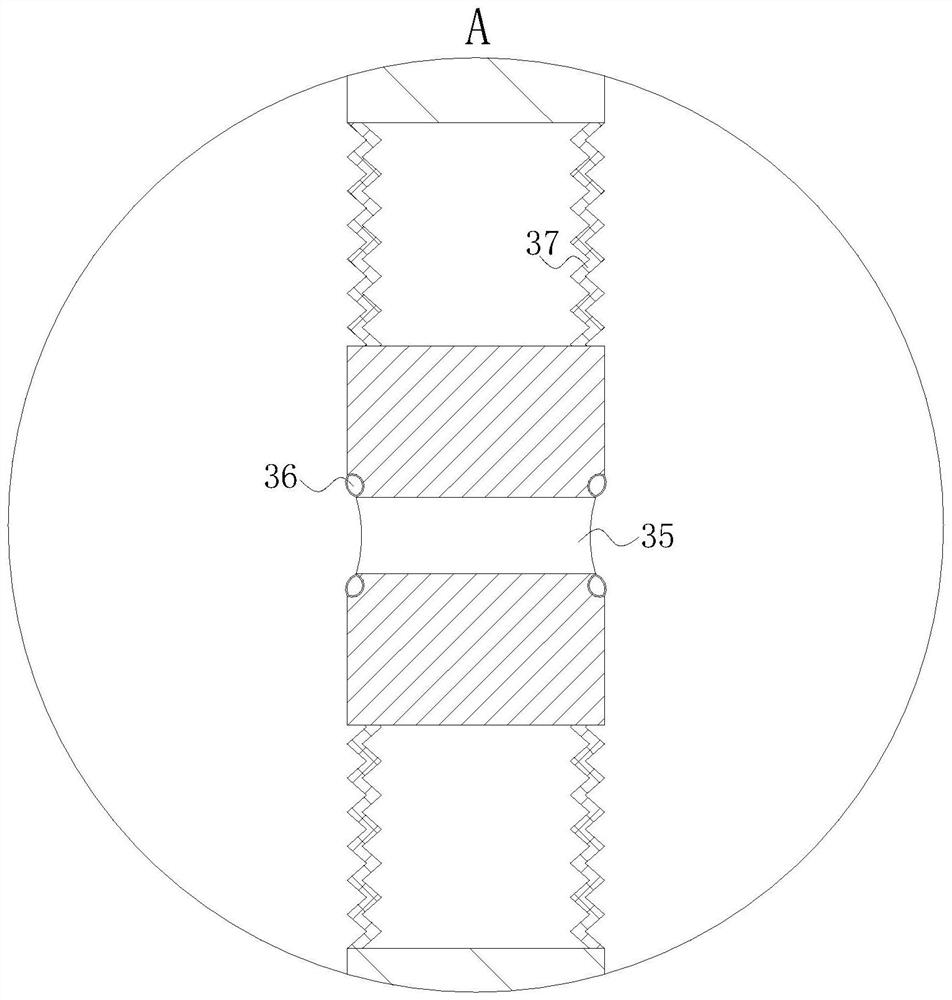

[0018] use Figure 1-Figure 3 A coil assembly according to an embodiment of the present invention will be described below.

[0019] Such as Figure 1-Figure 3 As shown, a coil assembly according to the present invention includes an operating table 1, a rotating handle 2, a finishing mechanism 3, a motor 4 and a winding wheel 5, and a mounting frame 11 is fixedly installed on the left upper surface of the operating table 1 The outer surface of the rear end of the mounting frame 11 is rotated with a traction wheel 12; the rear end of the traction wheel 12 is fixedly equipped with a rotating handle 2; the right side of the rotating handle 2 is provided with a finishing mechanism 3; Mechanism 3 is fixedly installed above the middle part of console 1, and the right side of finishing mechanism 3 is provided with winding wheel 5, and finishing mechanism 3 comprises installation frame 31, installation rod 32, No. 1 sliding rod 33, No. 2 sliding rod 34 and guide Holes 35; the rewindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com