Material turnover device with height automatic to adjust

An automatic adjustment and height technology, applied in the direction of lifting device, lifting equipment safety device, lifting frame, etc., can solve the problems of reducing work intensity, high work intensity, inconvenient material retrieval, etc., to reduce work intensity, reduce labor intensity, The effect of easy retrieval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

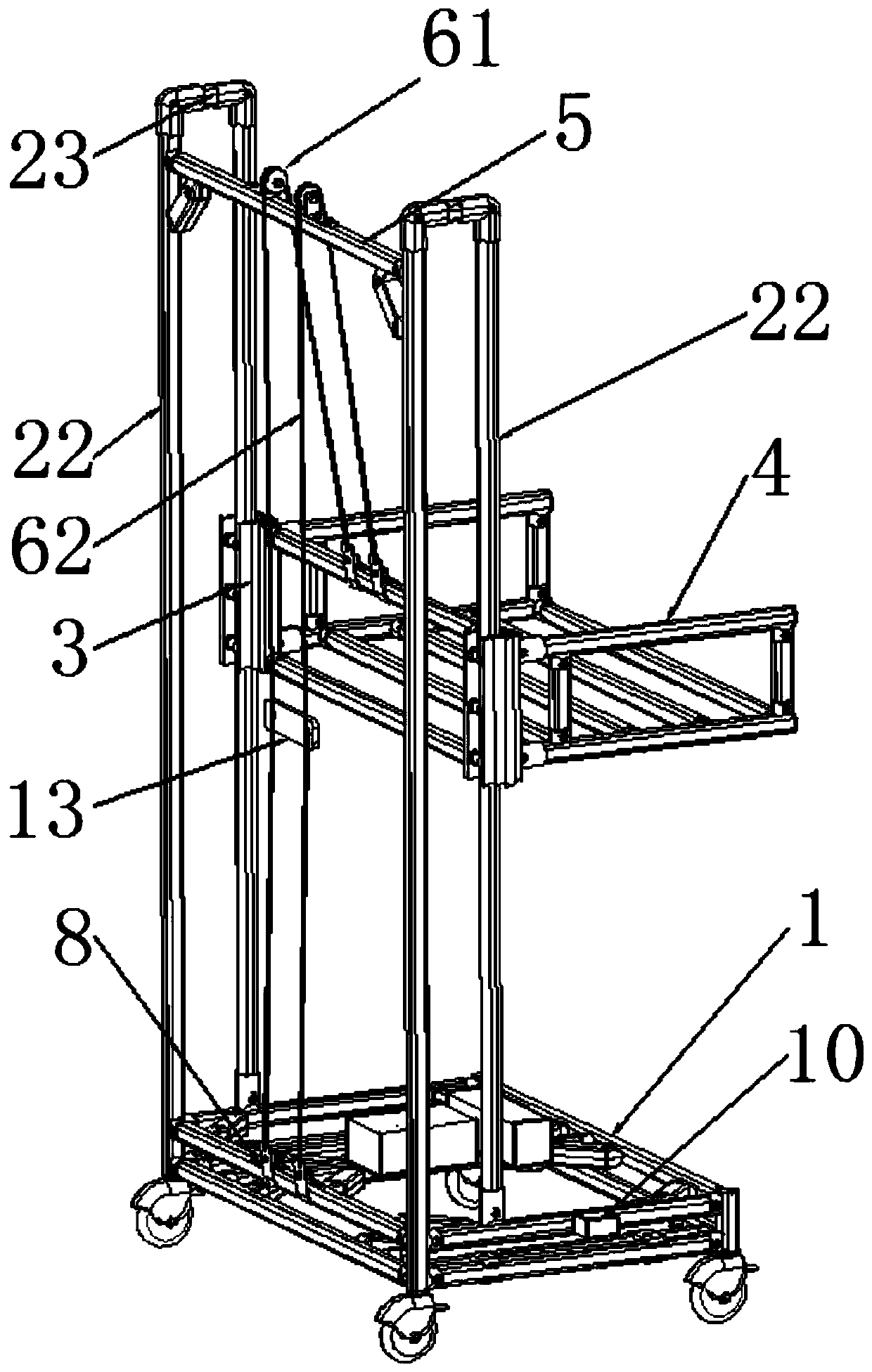

[0036] A material turnover device with automatic height adjustment, such as figure 1 As shown, a movable base bracket 1 is included, and the base bracket 1 is used to move the device; the base bracket 1 is provided with a guide support frame, and one side of the guide support frame is provided with a guide seat 3 for sliding cooperation. When the guide seat 3 slides, The guide support frame limits its movement direction; the guide seat 3 is provided with a rack 4, and the guide seat 3 moves to drive the storage rack 4 to move; a support rod 5 is installed on the upper part of the guide support frame, and a pulley block is arranged on the support rod 5, and the pulley block makes the wire rope 62 move. The movement is smoother; the pulley block includes a fixed pulley 61 and a wire rope 62 wound on the fixed pulley 61, one end of the wire rope 62 is connected to the rack 4, and the wire rope 62 gives the moving force of the rack 4; the base bracket 1 is installed with a high ela...

Embodiment 2

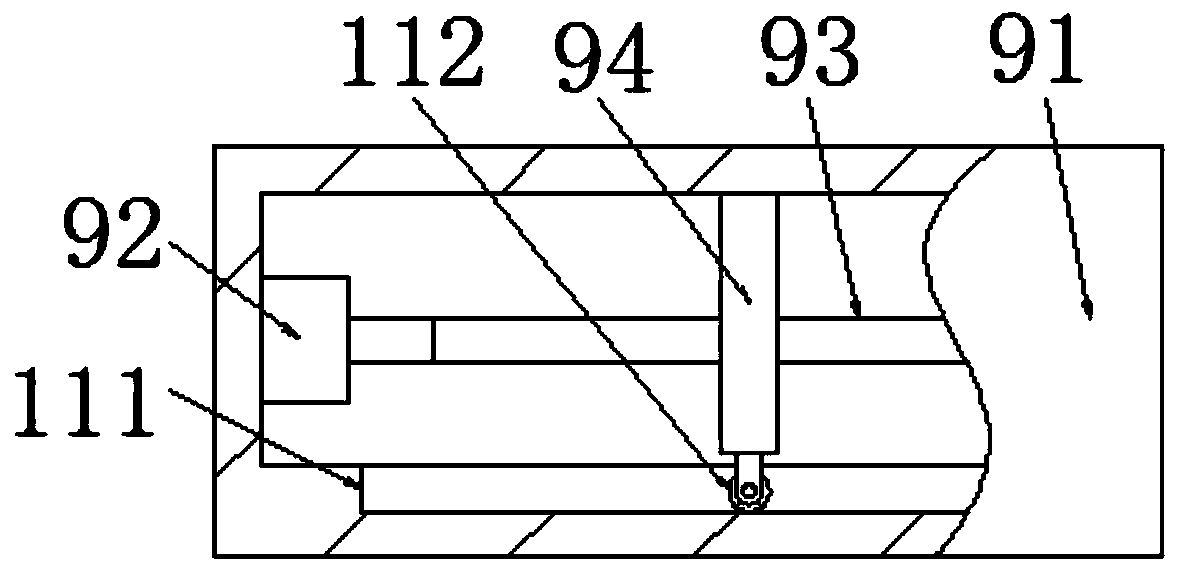

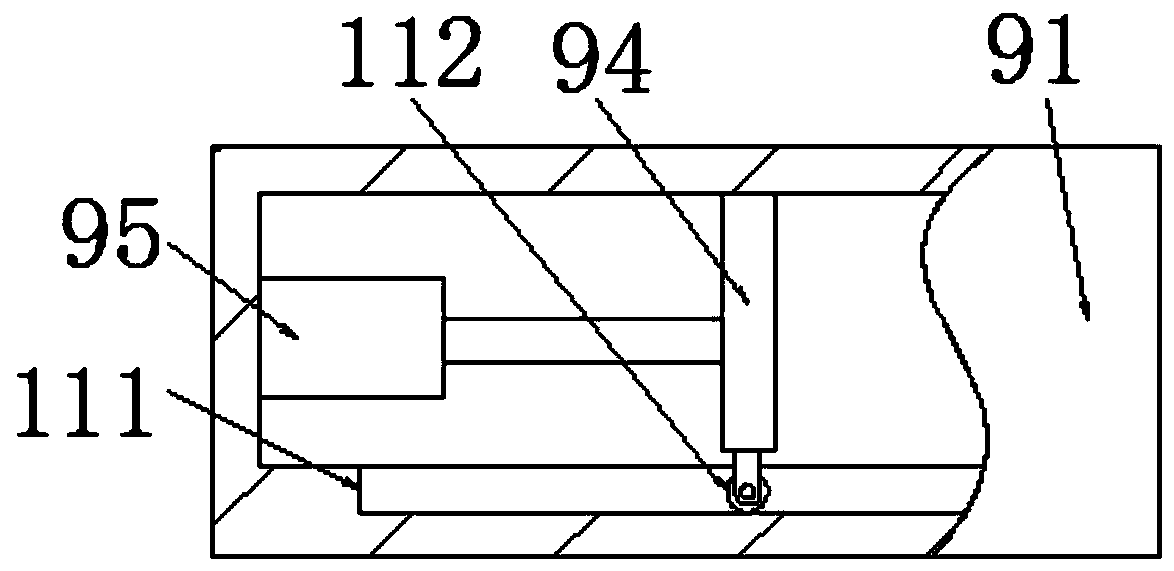

[0047] like image 3 and Figure 4 As shown, the adjustment mechanism includes a casing 91, an electric push rod 95 and a counterweight 94, the casing 91 is mounted on the base bracket 1, the electric push rod 95 is connected with the controller, and the controller controls the electric push rod 95. Work; a counterweight 94 is installed on the movable end of the electric push rod 95, and the electric push rod 95 drives the counterweight 94 to move. When the controller controls the adjustment mechanism to adjust, the controller activates the electric push rod 95, and the movable end of the electric push rod 95 expands / contracts, thereby driving the counterweight 94 to move.

Embodiment 3

[0049] On the basis of Example 1 and Example 2, as Figure 9 As shown, a limit rod assembly is installed on the guide support frame, and the limit rod assembly limits the position of the operator when placing the material; the limit rod assembly includes a limit support rod 121 and a telescopic rod 122, and the limit support rod 121 A telescopic rod 122 is installed on the bottom surface; the movable end of the telescopic rod 122 is connected to the rack 4 , and the telescopic rod 122 expands and contracts with the movement of the material to ensure that the position limit function is always played.

[0050] like Figure 9 As shown, there are three sets of the limiting components, that is, the left side and the front and rear sides of the rack 4 are installed. When placing materials, operators can ensure accurate placement. In this case, there is also a tilt problem in the x-axis direction. In order to solve this problem, the level 10 is arranged in the x-axis direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com