Cast-in-place integrated heat insulation plate bolt hole plugging device and method

A plugging device and plate bolt technology, applied in building maintenance, construction, building construction, etc., can solve the problems of high-altitude plugging of bolt holes, such as time-consuming, labor-intensive, low construction efficiency, and high risk, so as to improve the plugging effect. It is not easy to disturb, and the effect of increasing deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

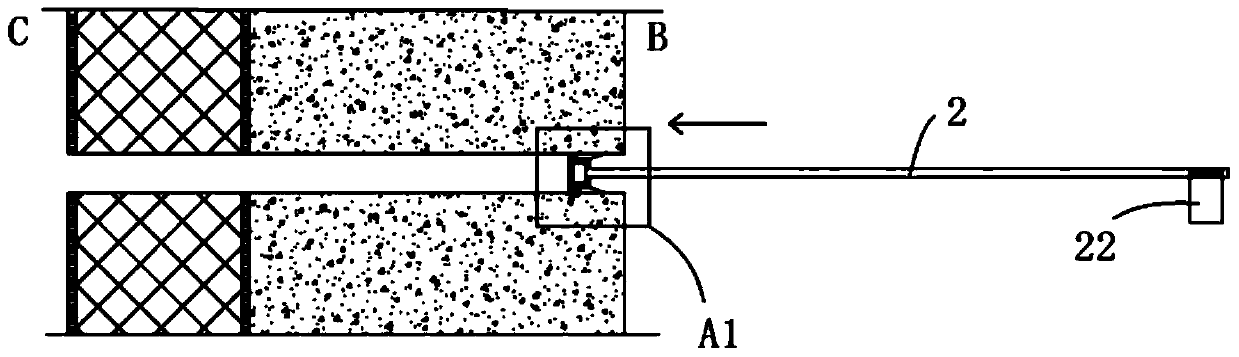

[0038] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

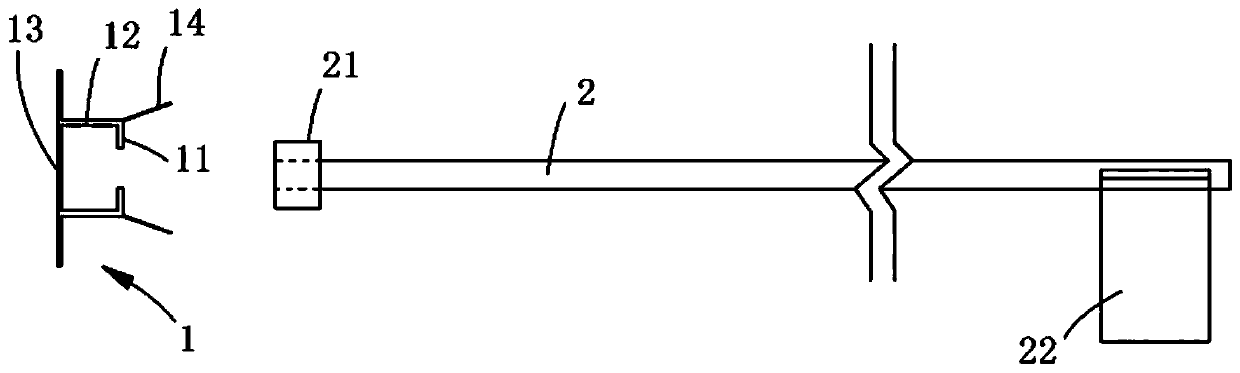

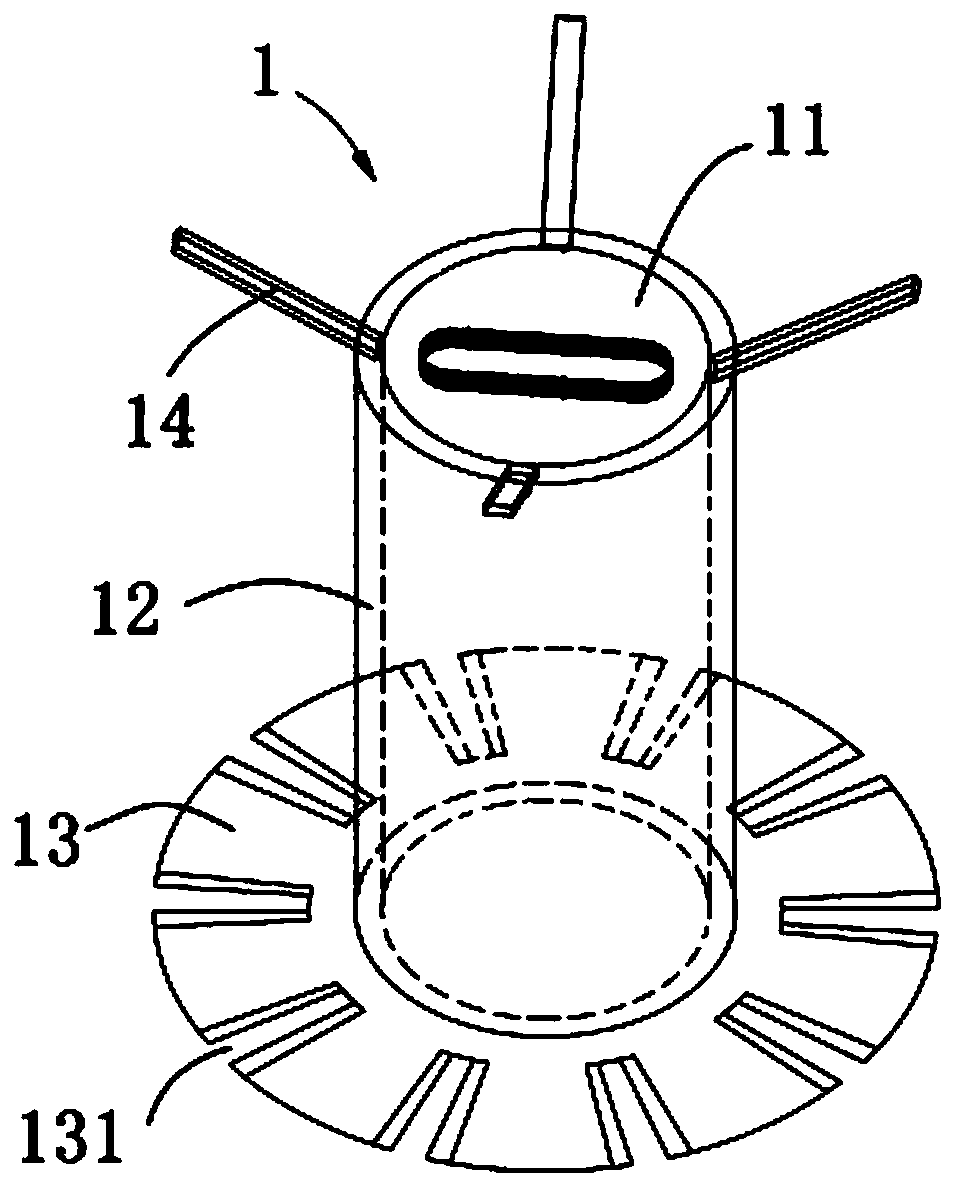

[0039] see figure 1 , figure 2 As shown, the present invention provides a bolt hole plugging device for a cast-in-place integrated insulation board, which is installed in the bolt hole to plug the bolt hole. The plugging device includes: a shrinkable end plugging part 1 and a grouting Pipe 2, the end blocking member 1 passes through the bolt hole when it shrinks, and one end of the bolt hole is blocked when the end blocking member 1 is unfolded, and one side of the end blocking member 1 is formed with The first clamping structure 11, the end of the grouting pipe 2 is provided with a second clamping structure 21, and the second clamping structure 21 and the first clamping structure 11 are engaged and clamped together.

[0040] In the embodiment of the present invention, the end blocking member 1 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com