A battery incubator processing device

A technology of processing device and incubator, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of reduced viscosity, large labor force, and complicated operation, and achieves the effect of improving efficiency and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

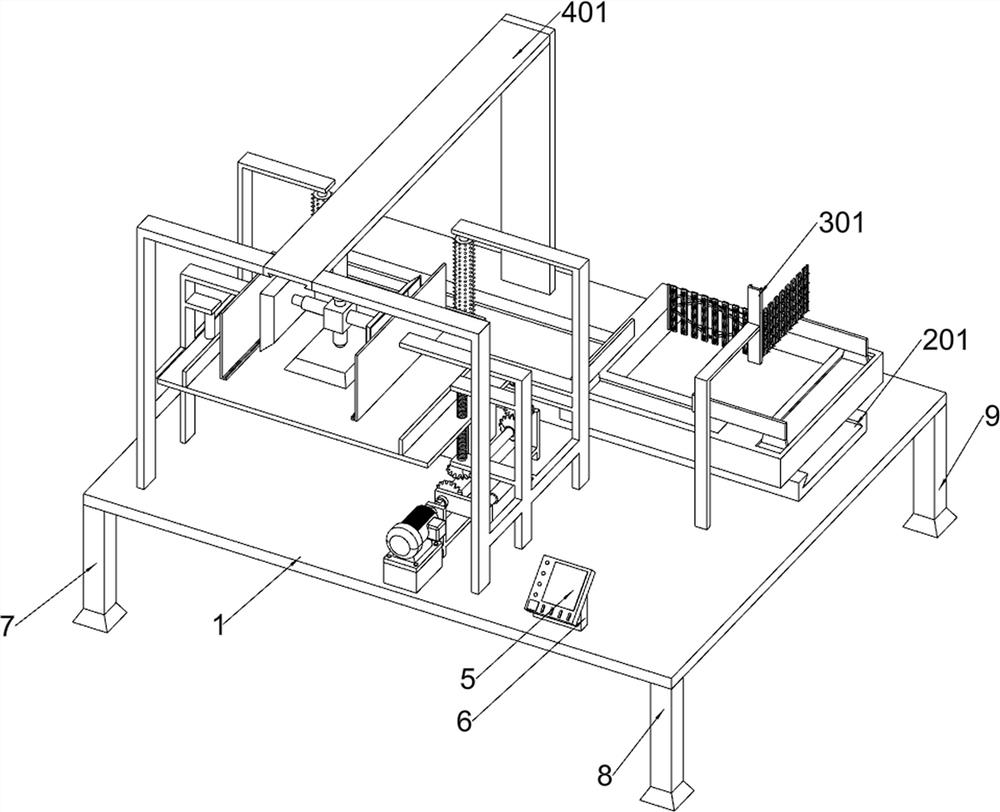

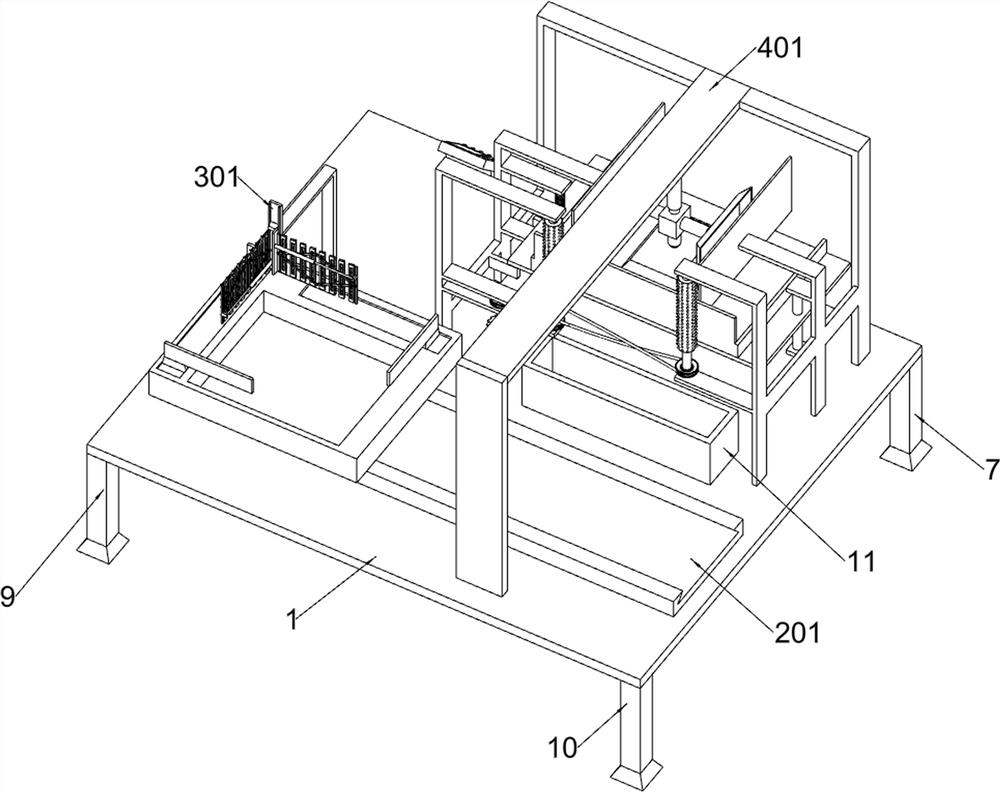

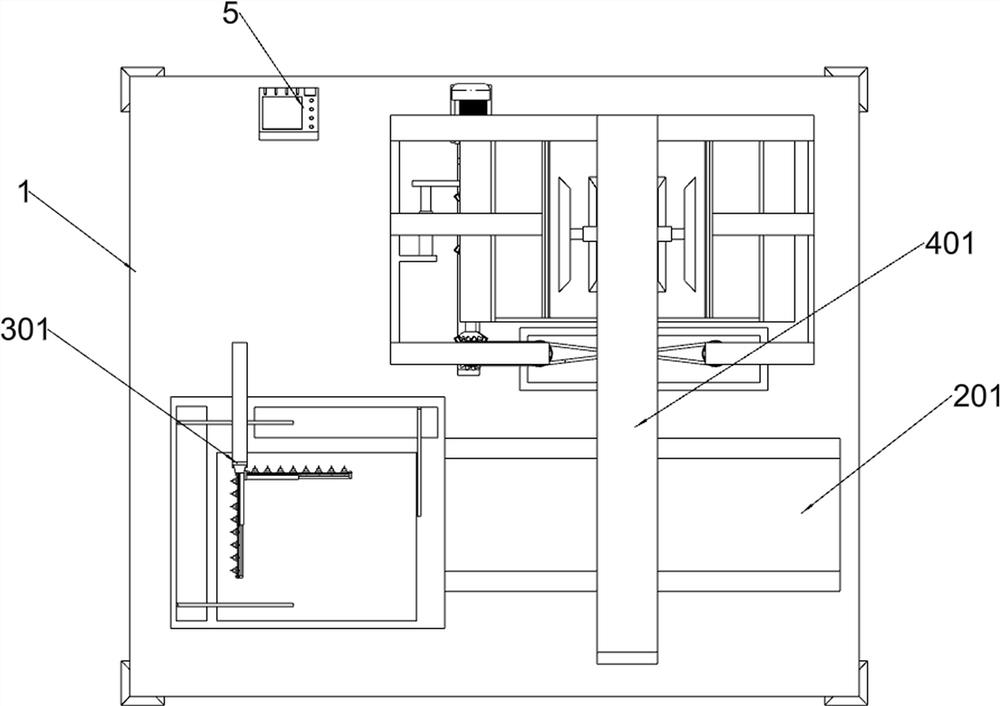

[0033] A battery incubator treatment device, refer to Figure 1-3 As shown, it includes a chassis 1, a groove unit, a bonding unit, a control panel 5, a first bracket 6, a first support 7, a second support 8, a third support 9, a fourth support 10 and A collection box 11; a first bracket 6 is installed above the right part of the underframe 1; a first support 7 is installed under the underframe 1; a second support 8 is installed under the underframe 1; a third support is installed under the underframe 1 Seat 9; a fourth support 10 is installed under the underframe 1; a collection box 11 is installed above the left part of the underframe 1; a first bracket 6 is installed under the control panel 5; a scribing unit is installed above the right part of the underframe 1; The scribing unit draws a groove on the inner wall of the incubator, and the two sides of the groove form upward and downward burrs; a fitting unit is installed on the upper left part of the chassis 1; the fitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com