A pipeline opening and closing control device

A technology for control devices and pipelines, which is applied in the direction of valve devices, valve operation/release devices, valve details, etc. Valve service life and other issues, to achieve the effect of reduced construction and maintenance costs, easy maintenance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

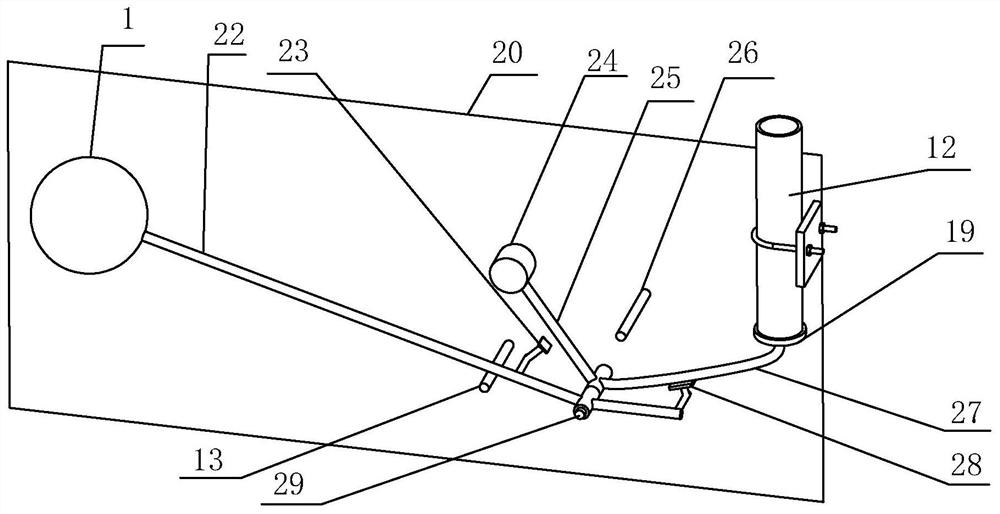

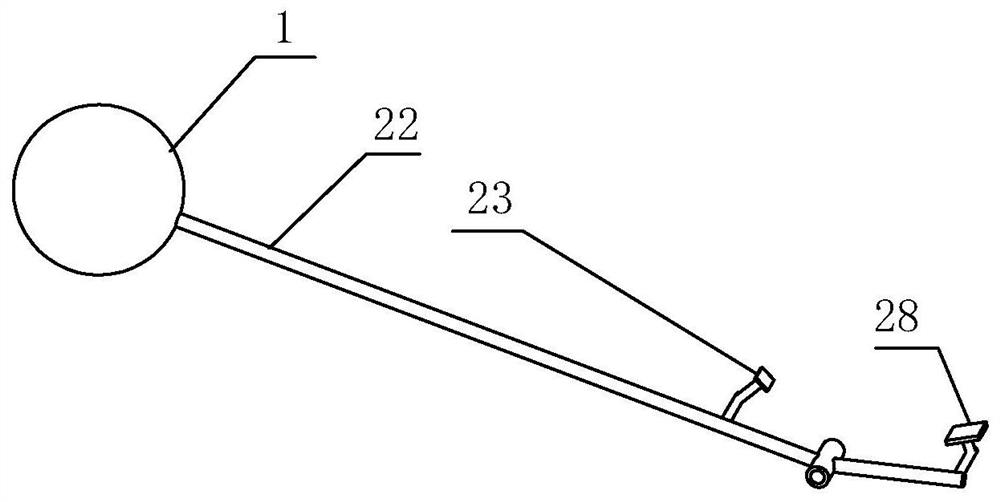

[0071] Such as figure 2 As shown, in this embodiment, the floating member 1 and the first connecting rod A22 are assembled: a hollow spherical structure is used as the floating member 1 in this embodiment, and the first connecting rod A22 includes a connecting end of the floating member and a first installation end 21 . The first connecting rod A22 is connected with the floating member 1 through the connecting end of the floating member. The first installation end 21 of the first connecting rod A22 is in the structure of a rotating sleeve A. The first connecting rod A22 is provided with a first trigger structure 23, a second The trigger structure 28, wherein the first trigger structure 23 faces the power receiving structure of the potential energy transmission mechanism, and the second trigger structure 28 faces the first connection structure 27 on the potential energy transmission mechanism.

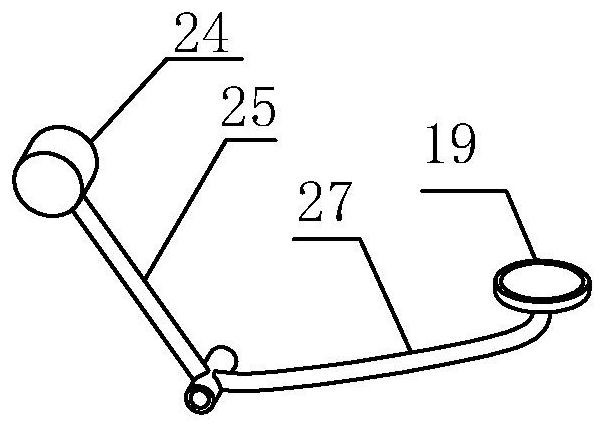

[0072] Such as image 3As shown, in this embodiment, the potential energy transmi...

Embodiment 2

[0076] In order to further improve the use effect of the present invention, prevent the pipeline closure from slowly opening or closing at a specific position due to the slow rise or fall of the floating member 1 when the liquid level rises or falls slowly, resulting in the opening and closing of the negative pressure pipe inlet. . Embodiment 2 provides a method of using multiple potential energy transmission mechanisms to realize high-level rapid full-level discharge. Prevent the pipeline blocking mechanism 19 from frequently switching between blocking the entrance of the negative pressure pipeline 12 and being away from the entrance of the negative pressure pipeline 12 due to the slow rise and fall of the liquid level when the pipeline blocking mechanism 19 is close to or away from the negative pressure pipeline 12 The situation makes the system open only at the highest point of the liquid level and close at the lowest point of the liquid level, making the opening and closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com