On-line detection device and method in strip-shaped FPC production

A detection device and strip-shaped technology, applied in the field of optical detection, can solve the problems that the detection rate is difficult to keep up with the production rate, it is difficult to obtain better detection results, and the imaging requirements are high, so as to reduce the influence of errors and overcome the blurring of captured images , the effect of reducing the analysis area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

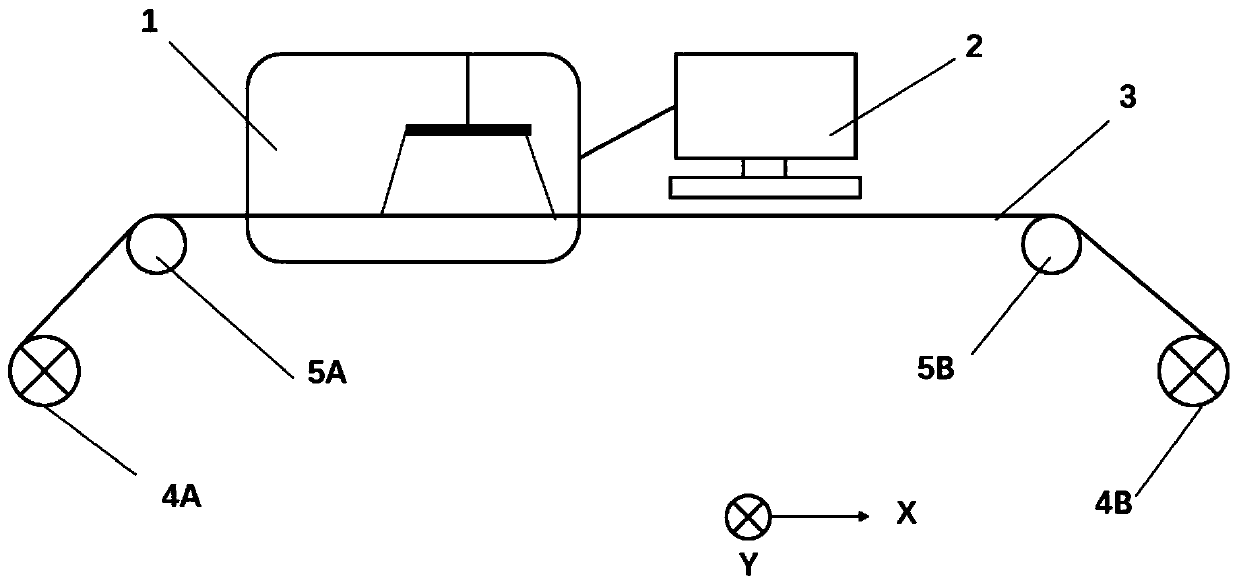

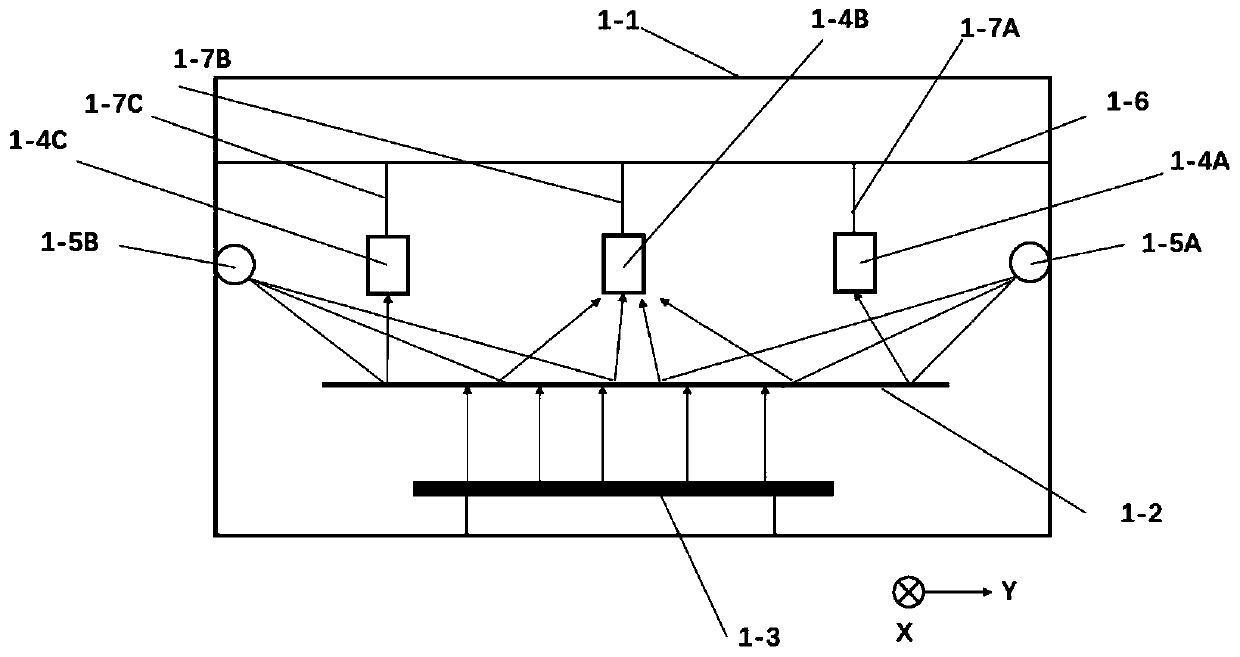

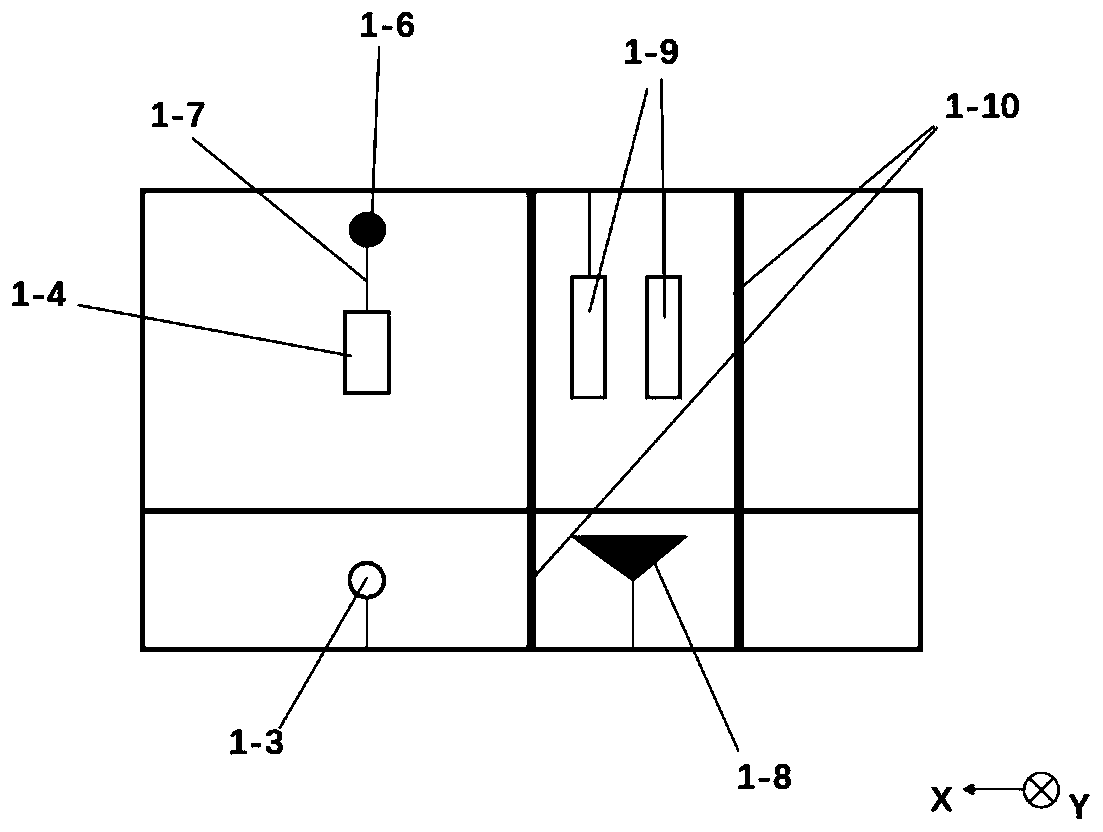

[0032] The on-line detection device in the production of strip-shaped FPC as shown in the figure includes the first pulling device 4A, the first movable adjustment roller 5A, the AOI detection equipment 1, the control and display platform 2, the first Two movable adjustable rollers 5B and a second pulling device 4B; AOI testing equipment 1 includes an equipment casing 1-1 and an equipment cavity, and the inside of the equipment cavity is provided with a lens holder 1-6 connected to the inner wall of the equipment casing; FPC3 passes through the inside of the equipment cavity and is located below the lens holder 1-6; a backlight light source 1-3 is provided below the strip-shaped FPC3; a first lens that can move along the Y direction on the lens holder 1-6 is also arranged in turn. A lens fixing bracket 1-7A, a second lens fixing brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com