Finite element analysis method for stress performance of high-strength double-angle steel combined section component

A technology of combined section and analysis method, which is applied in the field of finite element analysis of the mechanical performance of high-strength double-angle steel composite cross-section members, can solve the problem that the mechanical performance of components cannot be fully reflected, the test cannot meet the needs of research, and the test results are representative. Not strong and other problems, to achieve the effect of satisfying the calculation accuracy, improving the efficiency, stability and solving efficiency of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A finite element analysis method for the mechanical performance of a high-strength double-angle steel composite section member includes the following steps:

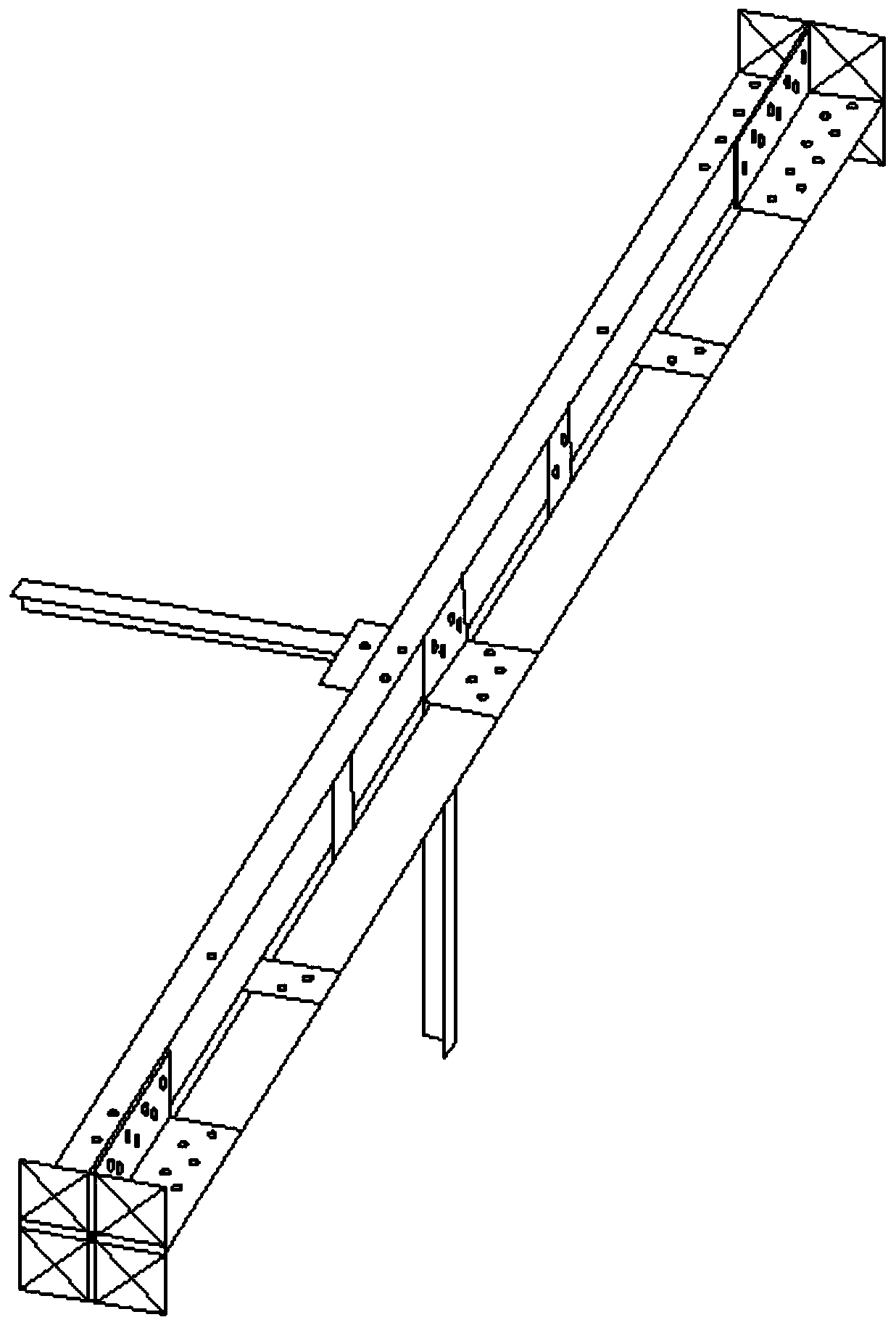

[0030] Such as figure 1 As shown, the geometric model of the cross-section member with double angle steel is established, and the shell element of SHELL181 is used to simulate the angle steel. The loose ratio is taken as 0.3, and the stress-strain relationship of the component material adopts the ideal elastic-plastic material model, that is, the double-broken model. In order to make the simulation closer to the actual situation, the tower plates at both ends of the component are added to the model to avoid stress concentration during It appears that the elastic modulus of the end plates at both ends of the component is increased to E=2.06e7MPa. The shell element has more advantages than the solid element in simulating such small and medium-thickness components. The calculation accuracy can meet the engineering re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com