Method for adjusting an operating point of a hydraulic actuator arrangement

A technology of operating points and facilities, applied in the direction of mechanical equipment, components with teeth, transmission device control, etc., can solve the problem that the operating points cannot be adjusted correctly, and achieve the effect of direct connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation

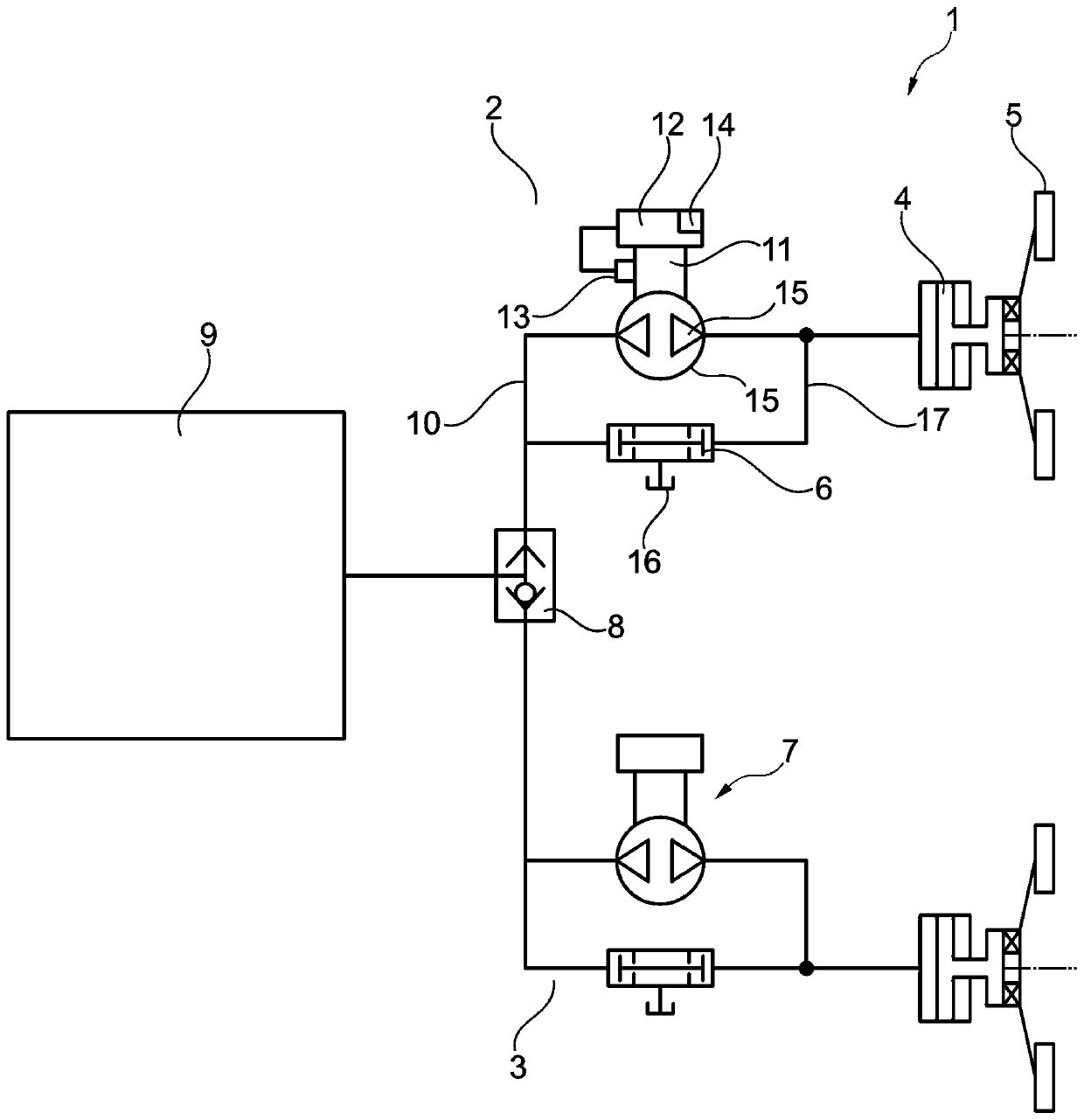

[0021] figure 1 , the pump actuator 1 is constructed as a dual-motor dual-clutch transmission. In the dual clutch transmission there are two sub-branches 2 , 3 , both of which comprise hydraulic cylinders 4 which actuate the clutch 5 . The respective hydraulic cylinder 4 of the clutch 5 is actuated via a dual-pressure valve 6 which is coupled to a pump actuator 7 . The two sub-branches 2 , 3 are connected to a transmission actuator 9 via a valve 8 .

[0022] Since the two sub-branches 2, 3 are constructed identically, only one sub-branch needs to be described. In each sub-branch 2 , 3 the line 10 is connected to a pump actuator 7 , which is driven by an electric motor 11 . The electric motor 11 is in turn driven by the control device 12 . Used to know the angular increment passed by the electric motor 11 The sensor 13 is arranged on the electric motor 11 . The switching signals of the sensor 13 are counted by a counter 14 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com