Two-stage gravity separation device for oil-containing wastewater treatment, and treatment process

A technology of gravity separation and wastewater treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, grease/oily substance/float removal device, etc. The problems of high intensity and labor intensity can achieve the effect of short residence time, increased oil-water separation efficiency, and small equipment footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

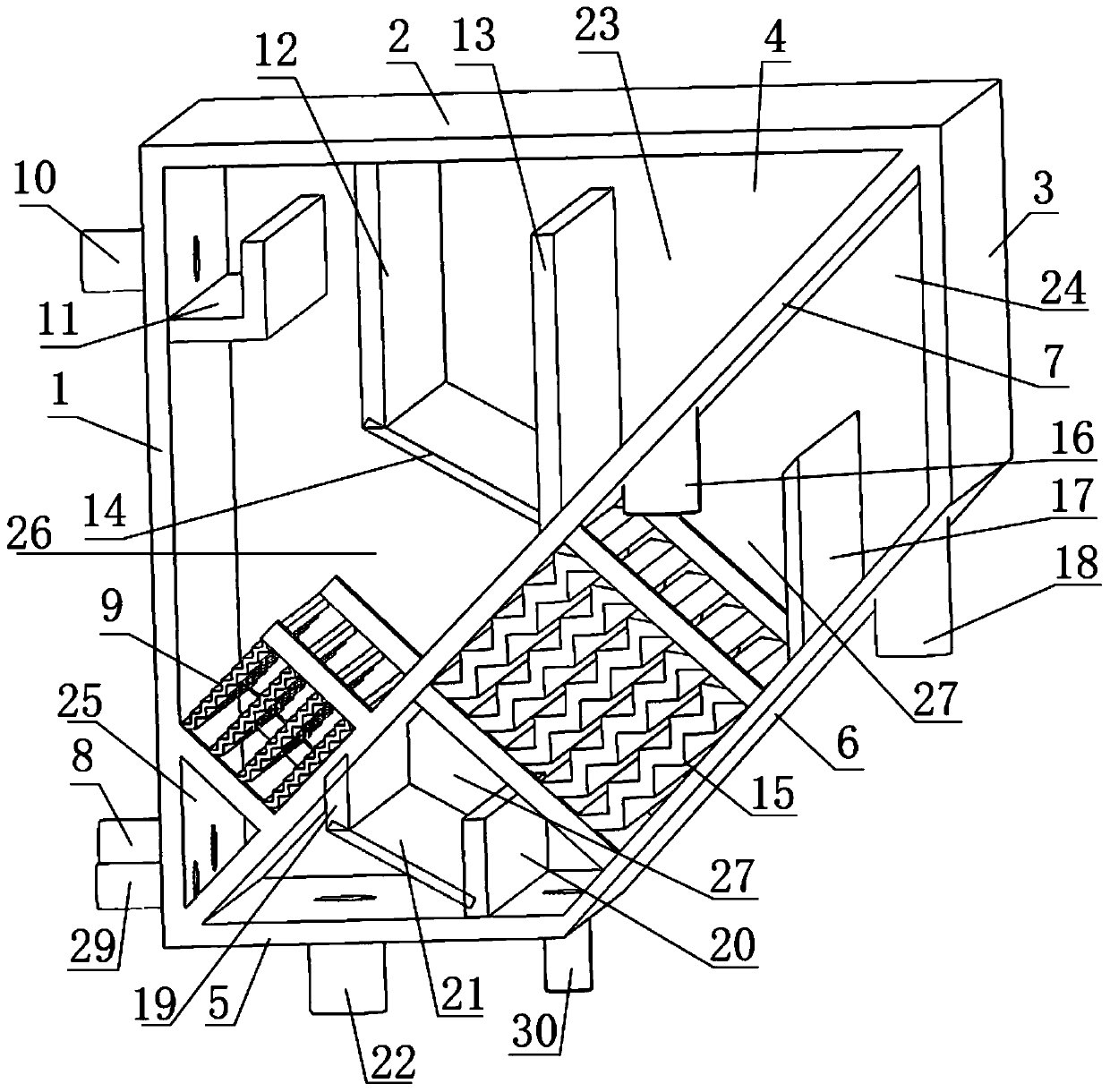

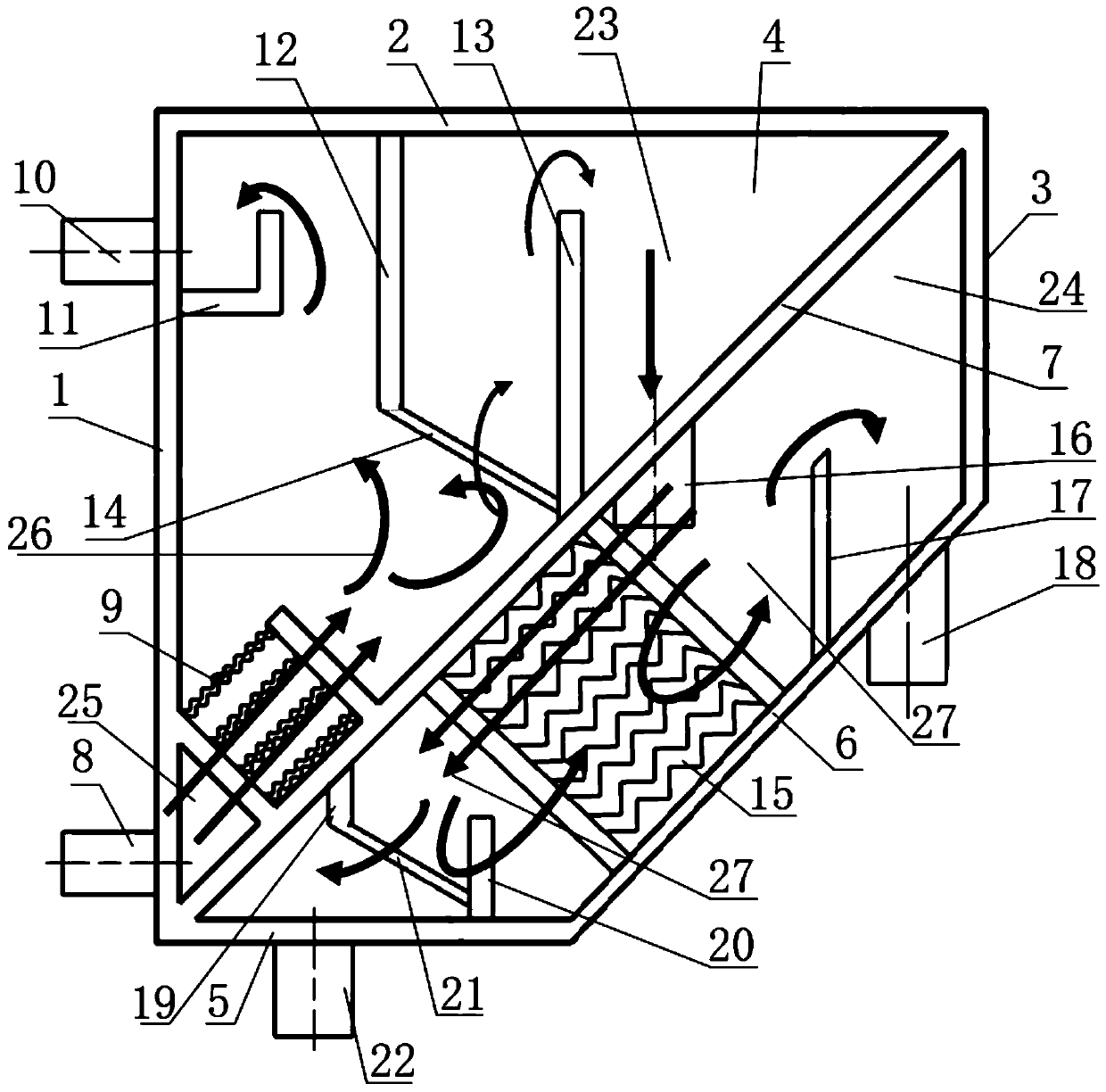

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] Such as figure 1 As shown, a two-stage gravity separation device for oily wastewater treatment includes a closed box, the box is composed of a bottom plate, a front side wall 1, a top plate 2, a rear side wall 3, a left side wall 4 and a right side wall (in the figure not shown, figure 1 is a schematic diagram of the structure after the right side wall is removed), the bottom plate of the box body is composed of a horizontal bottom plate 5 and a first slant plate 6 connected in sequence from front to back, and the first slant plate 6 is formed from front to back The rear direction is inclined upward, and the inside of the box body is provided with a second slant plate 7, the second slant plate 7 is inclined upward along the direction height from front to back, and the second slant plate 7 divides the inner space of the box body into a series of disconnected sections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com