Intelligent temperature-adjusting nonwoven fabric, intelligent temperature-adjusting coating and intelligent temperature-adjusting disposable sanitary article

A technology of intelligent temperature regulation and non-woven fabrics, applied in the direction of polyether coatings, coatings, etc., can solve the problem of not being able to achieve long-term temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

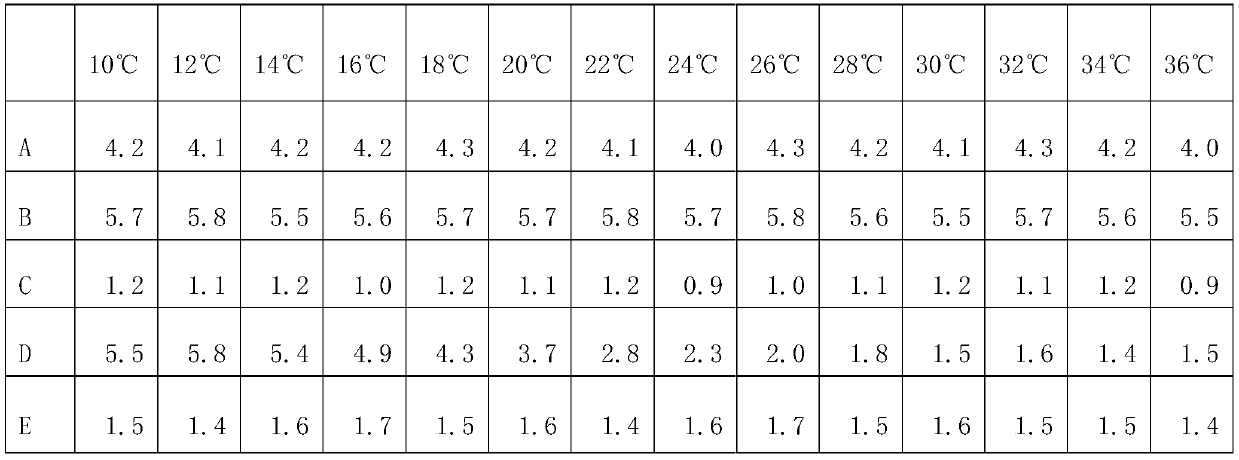

Image

Examples

Embodiment 1

[0028] The intelligent temperature-regulating paint of the present embodiment includes the following raw materials in parts by weight: 5 parts of tourmaline powder, 10 parts of polyethylene glycol type nonionic surfactants, 10 parts of isopropanol, 20 parts of amino polyether, epoxy-terminated polyether 20 parts ether silicone oil

[0029] Its production method is:

[0030] 1) grinding the tourmaline powder into a 50nm powder, and mixing it with a polyethylene glycol type nonionic surfactant to obtain a modified infrared radiation powder;

[0031] 2) Dispersing the modified infrared radiation powder into isopropanol to obtain a mixed solution;

[0032] 3) Add amino polyether and epoxy-terminated polyether silicone oil to the mixture to obtain an intelligent temperature-regulating coating.

Embodiment 2

[0034] The intelligent temperature-regulating coating of this embodiment includes the following raw materials in parts by weight: 5 parts of α-cordierite, 8 parts of polyethylene glycol type nonionic surfactant, 10 parts of isopropanol, 20 parts of amino-terminated polyether, and 20 parts epoxy polyether silicone oil

[0035] Its production method is:

[0036] 1) Grinding the α-cordierite powder into a powder of 80nm, and mixing it with a polyethylene glycol surfactant to obtain a modified infrared radiation powder;

[0037] 2) Dispersing the modified infrared radiation powder into isopropanol to obtain a mixed solution;

[0038] 3) Adding amino-terminated polyether and epoxy-terminated polyether silicone oil to the mixed solution to obtain an intelligent temperature-regulating coating.

Embodiment 3

[0040] The intelligent temperature-regulating paint of this embodiment includes the following raw materials in parts by weight: 10 parts of transition metal oxides, 10 parts of polyethylene glycol type nonionic surfactants, 10 parts of isopropanol, 20 parts of amino-terminated polyethers, and 20 parts epoxy polyether silicone oil

[0041] Its production method is:

[0042] 1) Infrared radiation powder of transition metal oxide system (Fe 2 o 3 -MnO 2 -CuO) is ground into 80nm powder, mixed with polyethylene glycol type nonionic surfactant high-energy planetary ball mill, and treated with plasma radiation to improve surface activity and obtain modified infrared radiation powder;

[0043] 2) Dispersing the modified infrared radiation powder into isopropanol to obtain a mixed solution;

[0044] 3) Adding amino-terminated polyether and epoxy-terminated polyether silicone oil to the mixed solution to obtain an intelligent temperature-regulating coating.

[0045] Example 3

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com