Cooling hydraulic fracturing method for developing hot dry rock thermal energy

A dry-hot rock and fracturing technology, used in geothermal power generation, fluid extraction, earthwork drilling, etc., can solve the problems of increasing development costs, cross-linked fracturing fluids failing to meet the temperature resistance requirements, and saving development costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

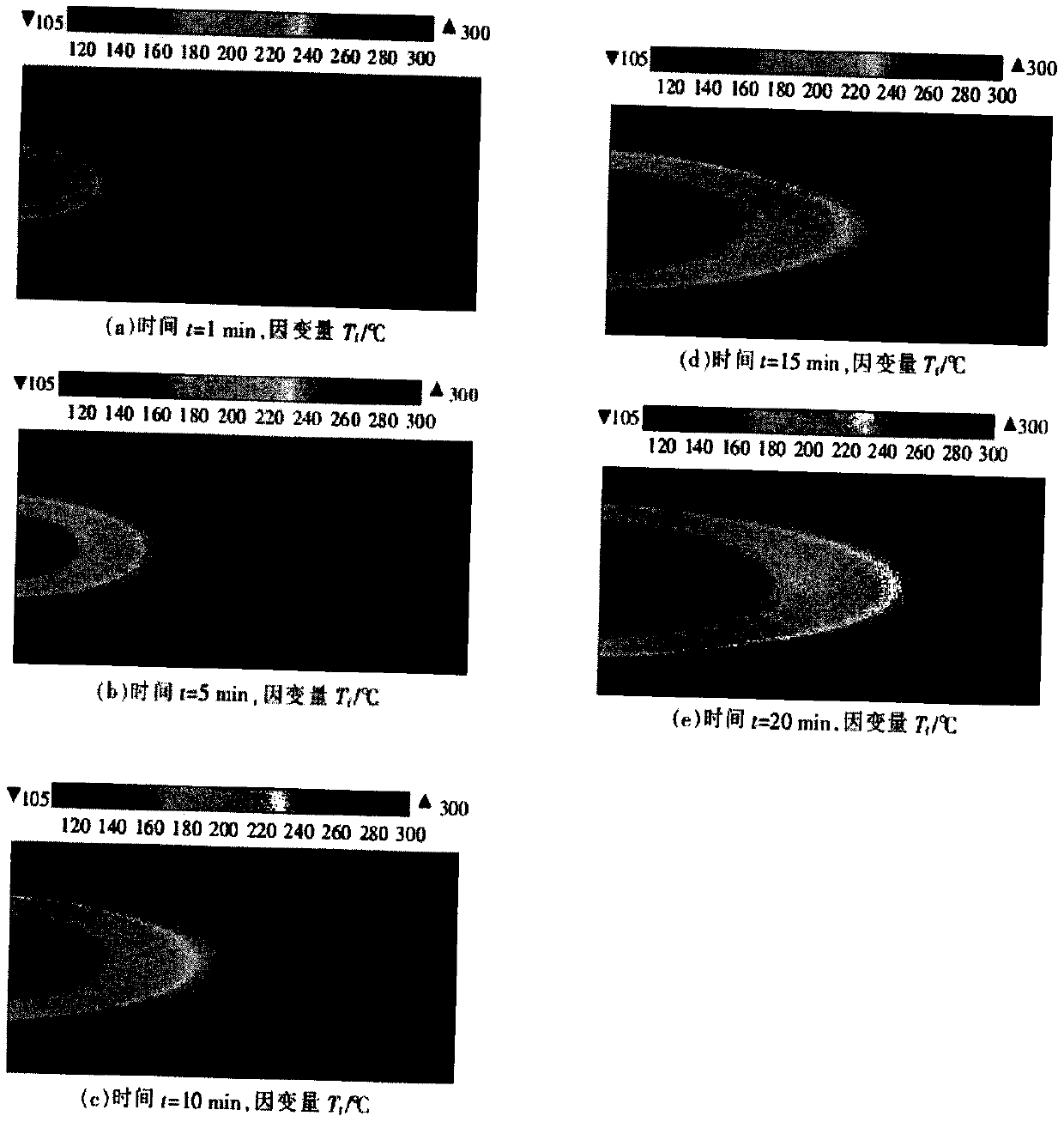

[0020] In a specific implementation manner of the present invention, a geothermal gradient of 7° C. / 100 m is taken as an example. Within 55m of the front of the fracture, the temperature difference between the fluid in the fracture and the formation has reached over 80°C, and the volume of the fracturing fluid at this time is 100m 3 .

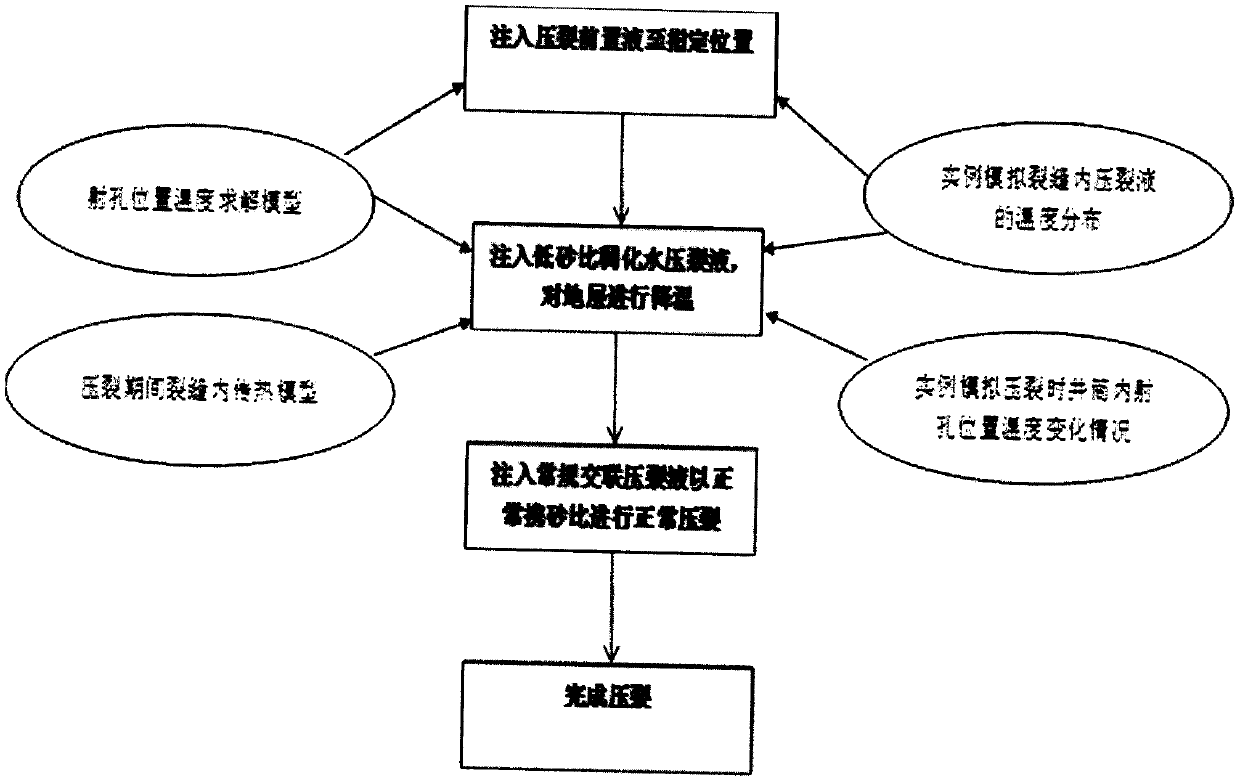

[0021] Such as figure 1 As shown, the hot dry rock thermal energy development cooling fracturing method of the present invention comprises the following steps:

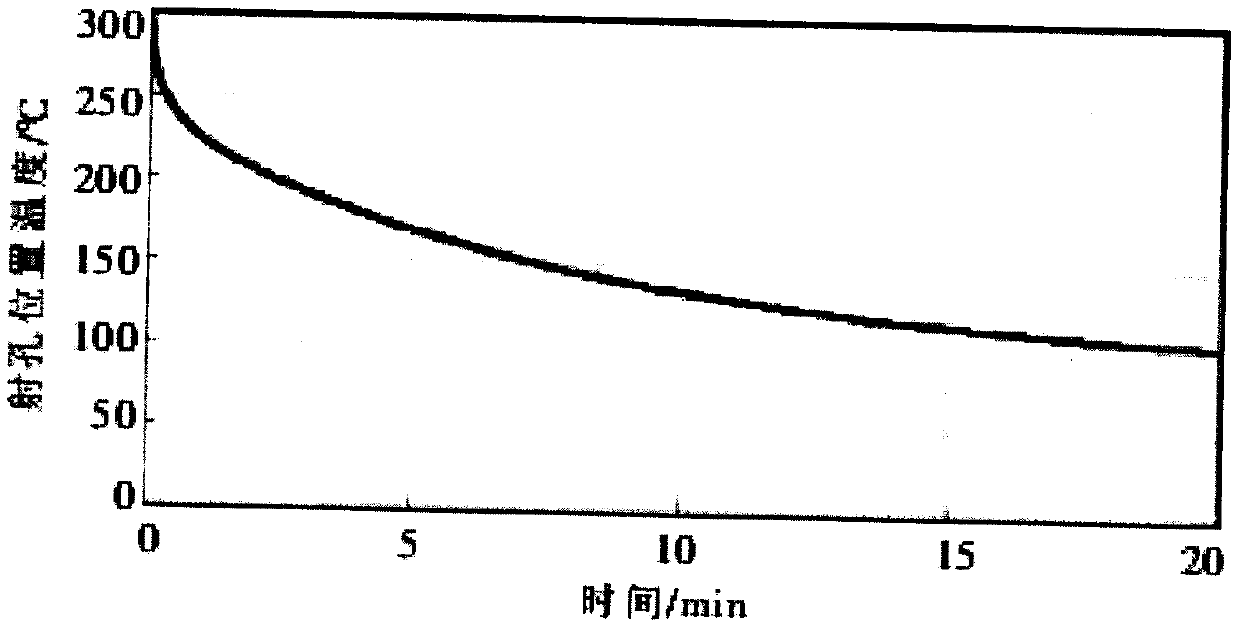

[0022] Step 1: In one embodiment of the present invention, the formation temperature at 4000 m downhole of the geothermal well is 300°C. During the fracturing process, the injection of pre-fluid clean water has a good cooling effect on the wellbore. By calculating the temperature distribution of the fracturing fluid in the fracture, as shown in image 3 As shown, the cooling eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com