Low-cost oil buffer

A low-cost technology for oil pressure buffers, applied in the field of oil pressure buffers, can solve the problems of high cost, easy cracking and damage, difficult replacement, etc., and achieves a simple installation process, improved buffer effect, and low disassembly and assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

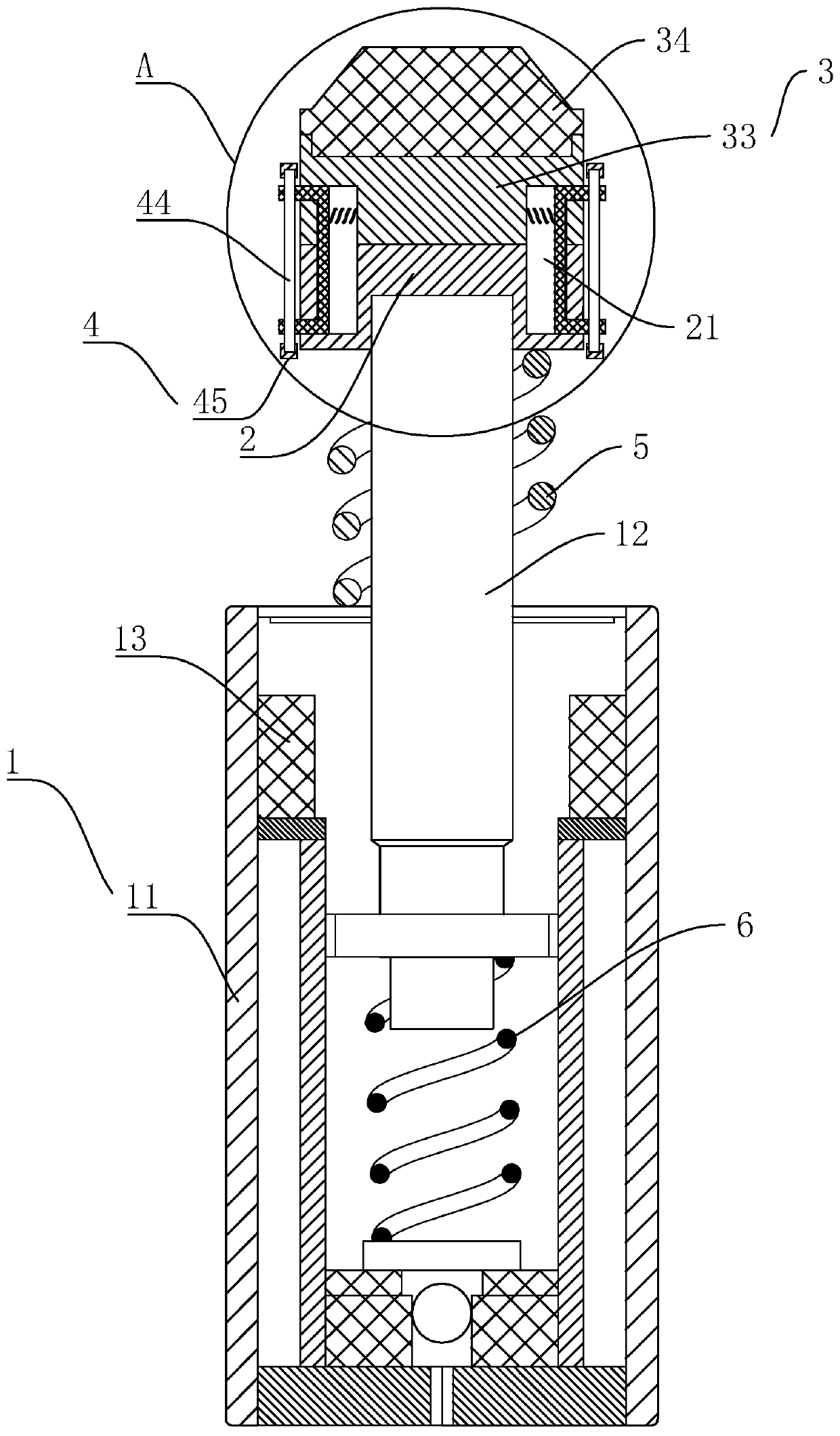

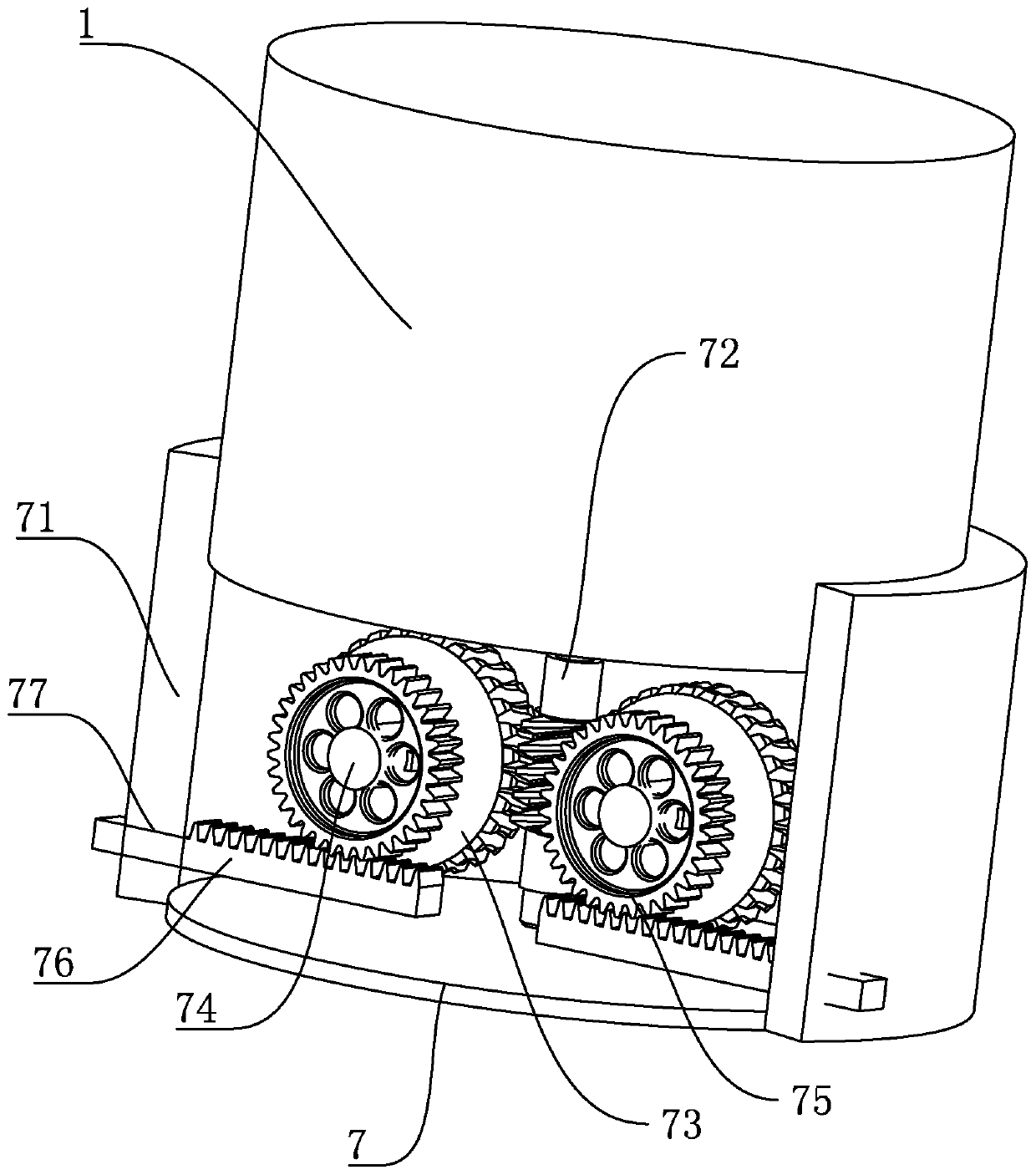

[0028] A low-cost oil pressure buffer provided in this embodiment has a structure such as Figure 1-3 As shown, it includes a buffer body 1, a buffer rod 12 slidably connected in the buffer body 1, and an impacted head 2 arranged at the end of the buffer rod 12. The side of the impacted head 2 facing away from the buffer rod 12 is provided with a sound-absorbing The cover 3, the sound-absorbing cover 3 and the impacted head 2 are fixedly connected to each other through the connecting piece 4.

[0029] The buffer body 1 includes a shell 11 and a pressure-accumulating sponge 13 arranged in the shell 11. A buffer spring 5 is fixed between the impacted head 2 and the shell 11. A connecting spring 6 is arranged in the shell 11, and the two ends of the connecting spring 6 are respectively fixed. On the bottom of the housing 11 and the buffer rod 12.

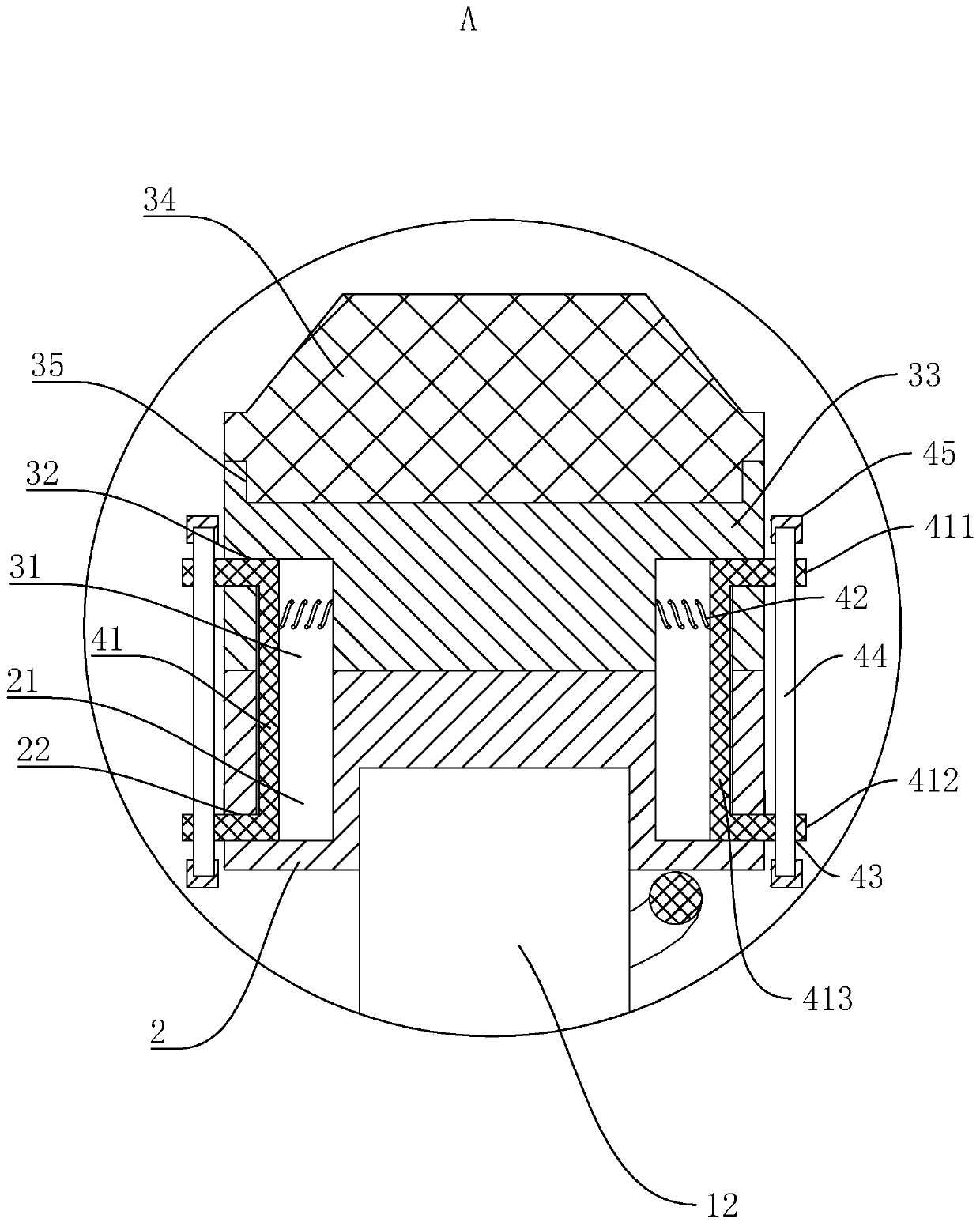

[0030] The connector 4 includes a receiving groove 21 that is vertical to the horizontal plane and is opened in the impacted head 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com