Hydraulic pipeline joint

A technology for hydraulic pipelines and pipe joints, applied in the direction of pipes/pipe joints/fittings, adjustable connections, pipeline protection, etc., can solve problems that affect work progress, increase costs, and reduce work efficiency, so as to speed up work efficiency and prevent impacts , The effect of leakage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

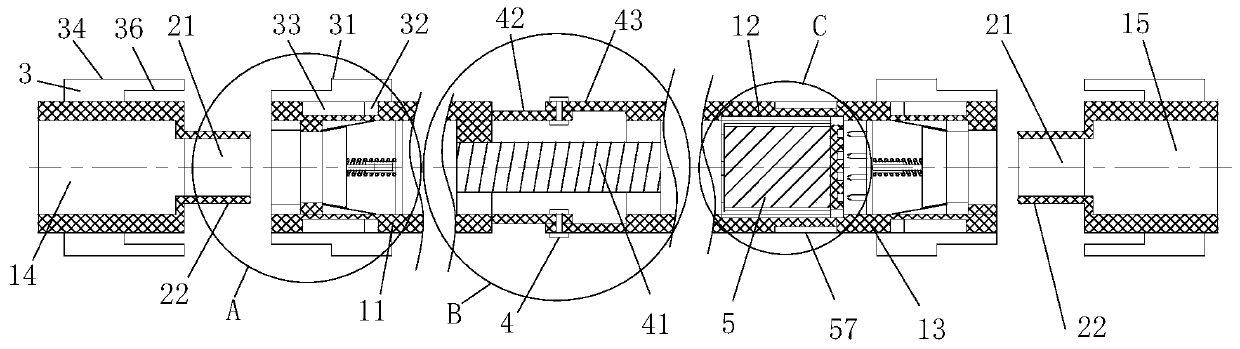

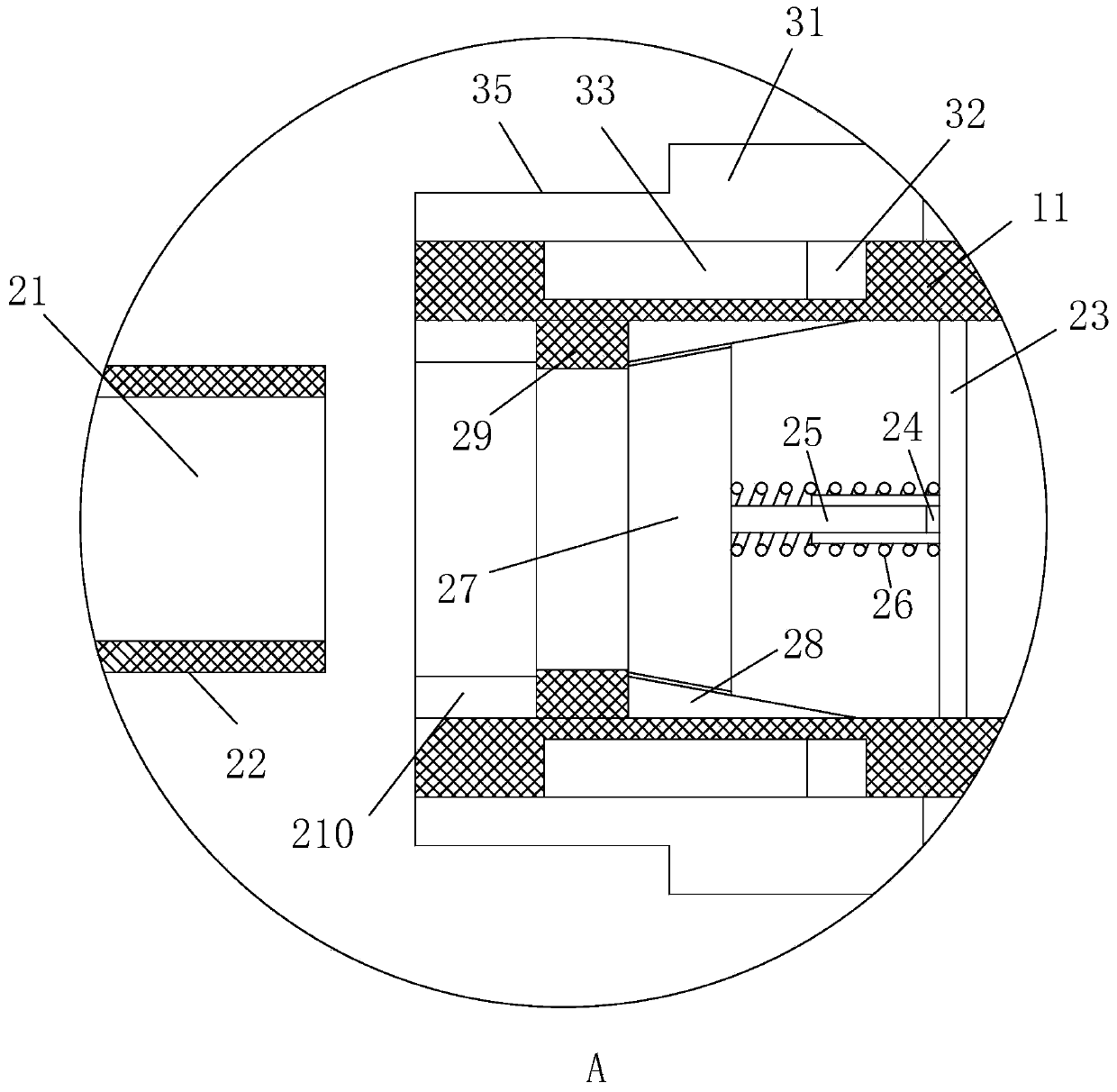

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

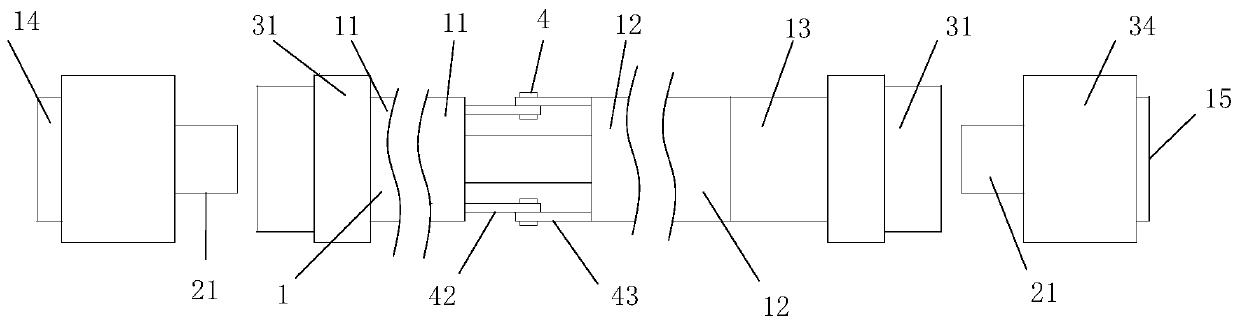

[0023] Such as Figure 1-Figure 5 As shown, a hydraulic pipeline joint according to the present invention includes a pipeline joint 1, a connecting mechanism 2, a protection mechanism 3, a steering mechanism 4, and a filtering mechanism 5. Both ends of the pipeline joint 1 are provided with a connecting mechanism 2, A protection mechanism 3 is provided on the outside of the connection mechanism 2 , and a steering mechanism 4 and a filter mechanism 5 are arranged inside the pipe joint 1 .

[0024] Specifically, the pipe joint 1 includes a first connecting pipe 11, a second connecting pipe 12, a third connecting pipe 13, a liquid inlet pipe 14, and a liquid outlet pipe 15. One end of the first connecting pipe 11 passes through a connecting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com