Hyperbolic-type cooling tower for thermal plant

A hyperbolic, cooling tower technology, applied in the cooling field of thermal power plants, can solve the problems such as the inability of the water blocker to collect water, the insufficient spray area, and the ineffective use of the cooling area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

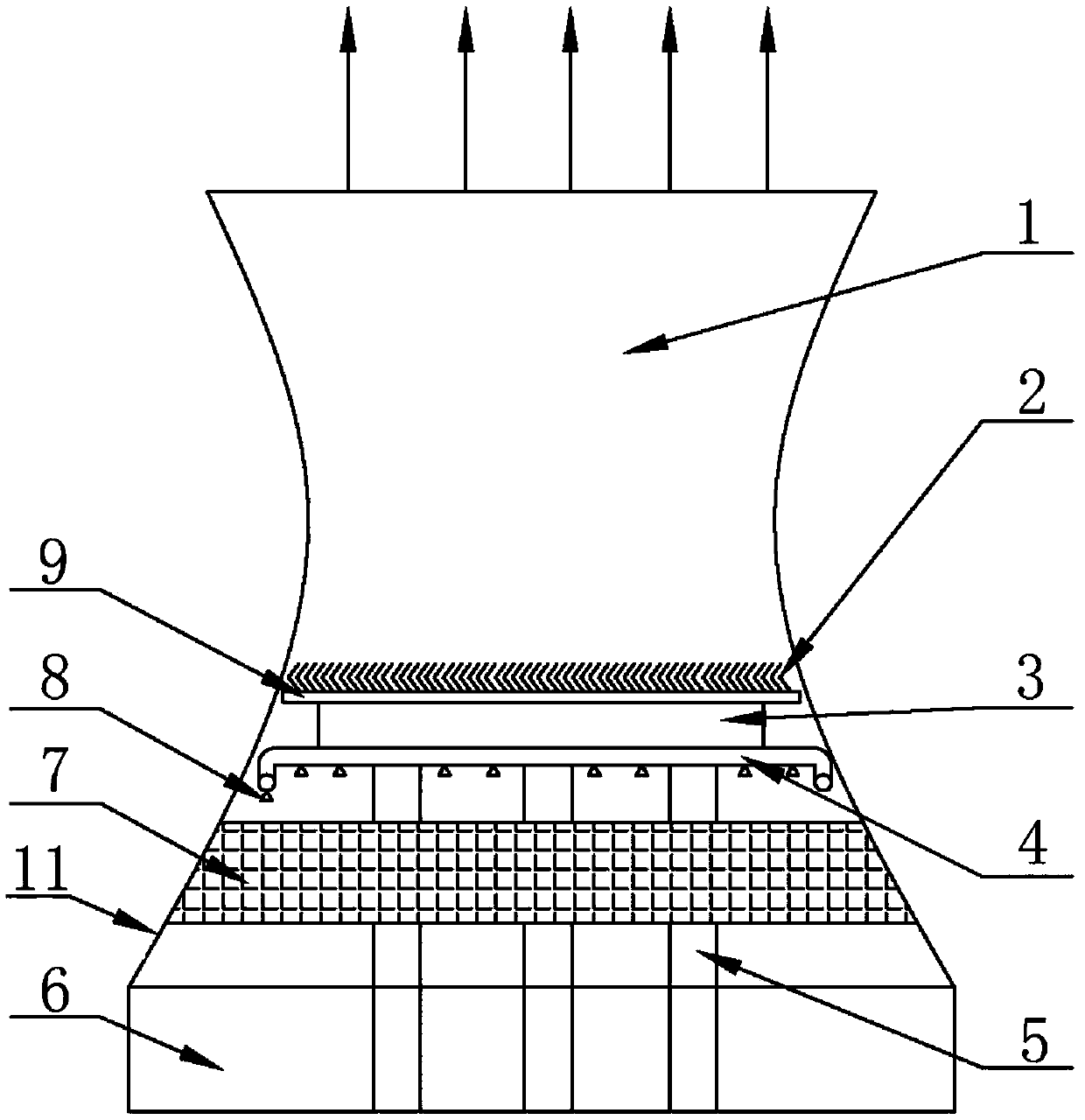

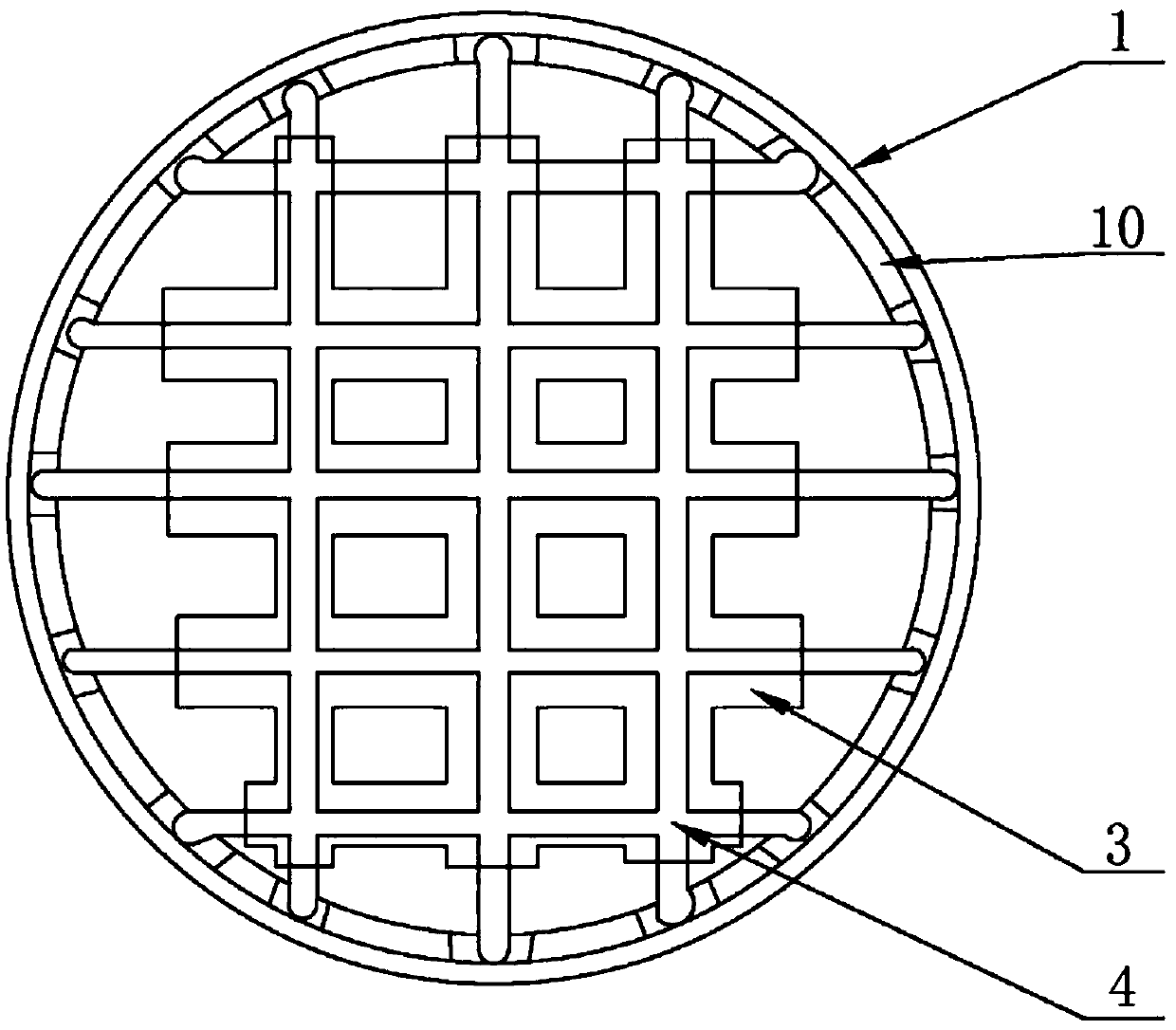

Embodiment 1

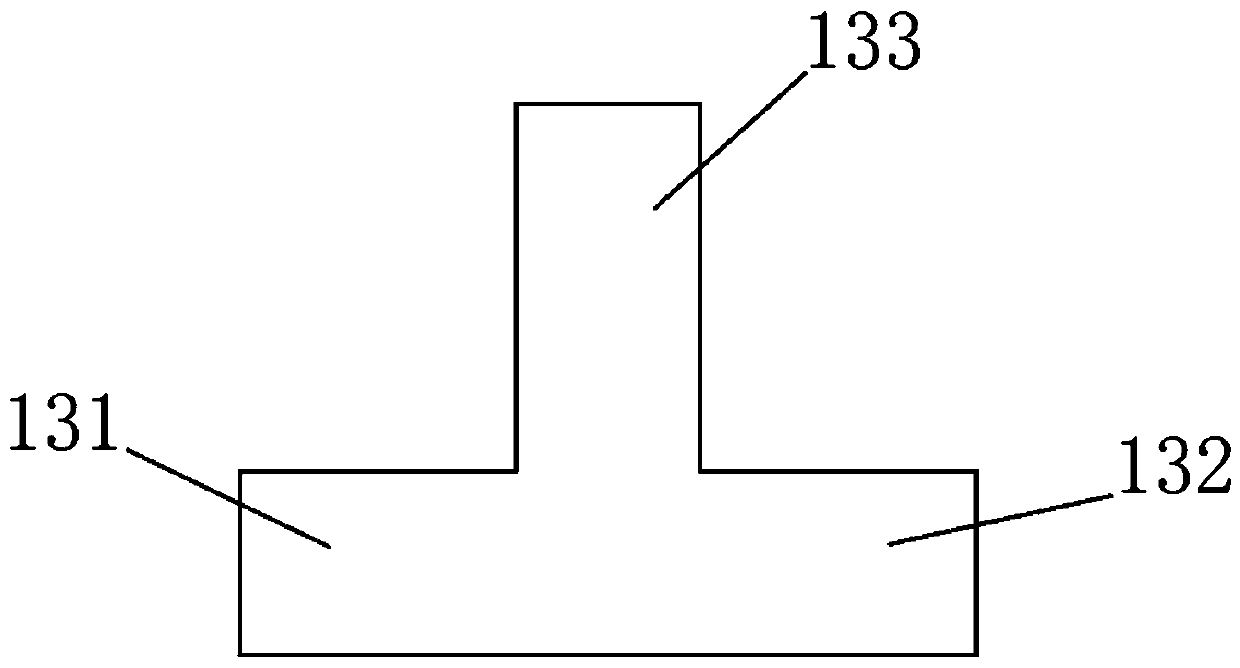

[0032] Such as figure 2 As shown, the supporting beam described in this embodiment includes a horizontal beam 3 arranged along the horizontal direction and a vertical beam 5 supporting the horizontal beam 3 and perpendicular to the horizontal beam 3. There are a plurality of vertical beams 5, and one end of each vertical beam 5 is perpendicular to the set The other end of the water basin 6 passes through the cooling device 7 and is connected to the crossbeam 3, and the crossbeam 3 is supported above the cooling device 7; figure 2 As shown, the water distribution pipes include a plurality of straight individual water distribution pipes 4 connected to each other, and the plurality of individual water distribution pipes 4 are arranged in a network structure inside the tower body and fixed on one side of the beam 6 facing the water collection basin. side, and one end of the single water distribution pipe 4 extends toward the inner wall of the tower, the single water distribution...

Embodiment 2

[0038] The difference between this embodiment and the above-mentioned first embodiment is that the water distribution pipe around the tower is set separately from the single water distribution pipe arranged in a mesh shape inside the cooling tower, and the single water distribution pipe extends to the side where the beam faces the tower wall. The edge position on the side avoids the problems of easy bending, deformation and breakage caused by the excessively long suspension of the single water distribution pipe. The inner wall of the cooling tower is also provided with a rotating device capable of controlling the water distribution pipe around the tower to rotate along the cooling tower, and the water distribution pipe around the tower is separately arranged from the single water distribution pipe. The water distribution pipe around the tower includes three or less circles The arc-shaped pipeline, the arc-shaped pipeline is fixedly connected by a two-way pipe or a flange to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com