Multi-layer synchronous measurement method for curved surface light-transmitting piece

A technology of synchronous measurement and light-transmitting parts, which is applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems that the curved surface structure cannot complete the measurement task, increase the cost of measurement, and reduce work efficiency, etc., to achieve simple structure, The effect of low-cost detection and short error transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below in conjunction with the accompanying drawings and examples.

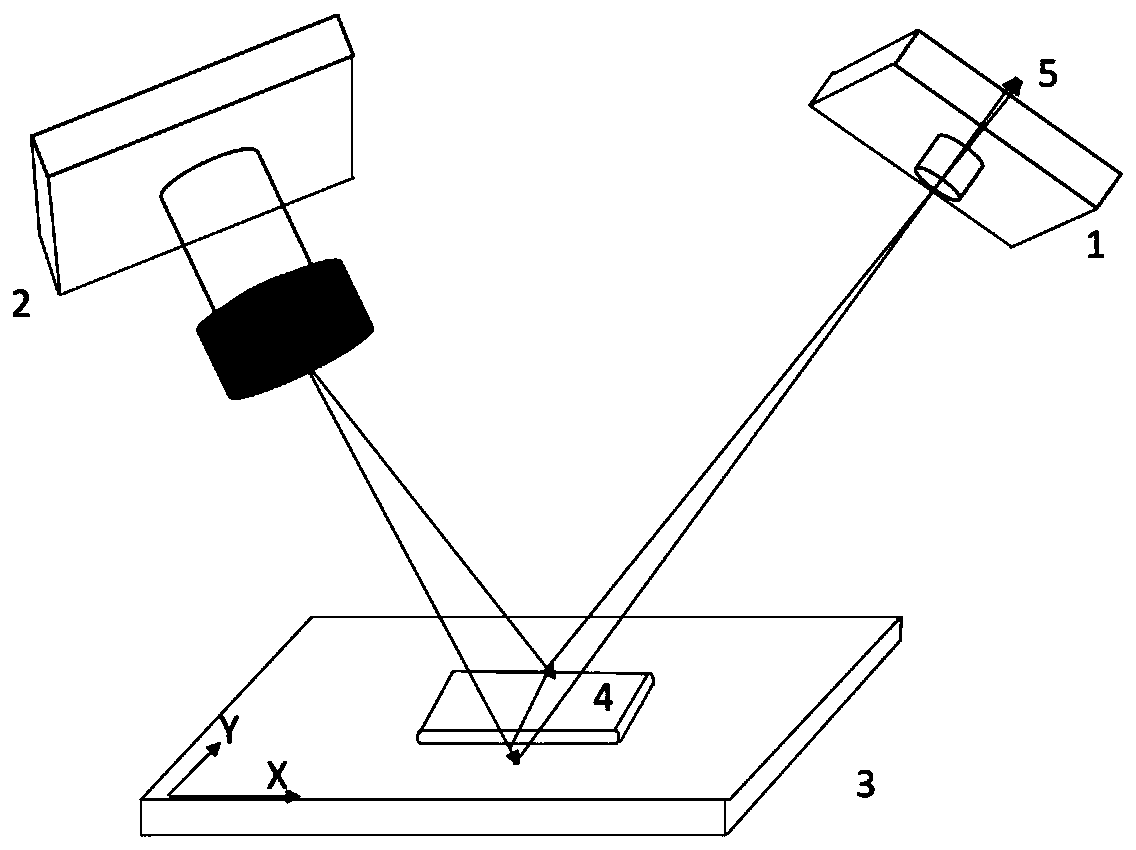

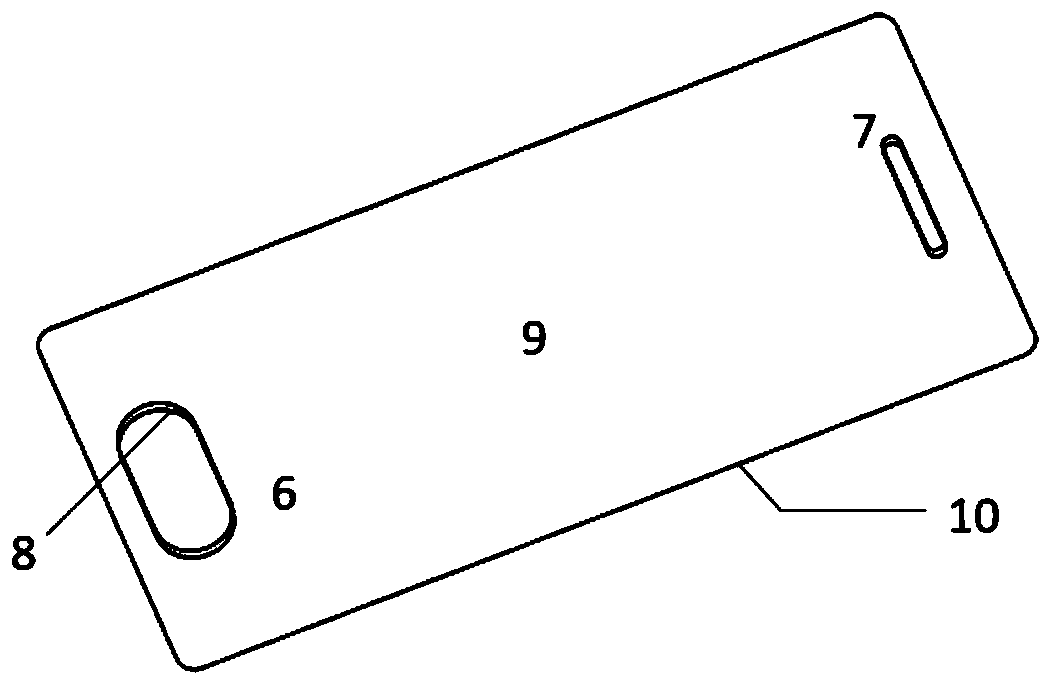

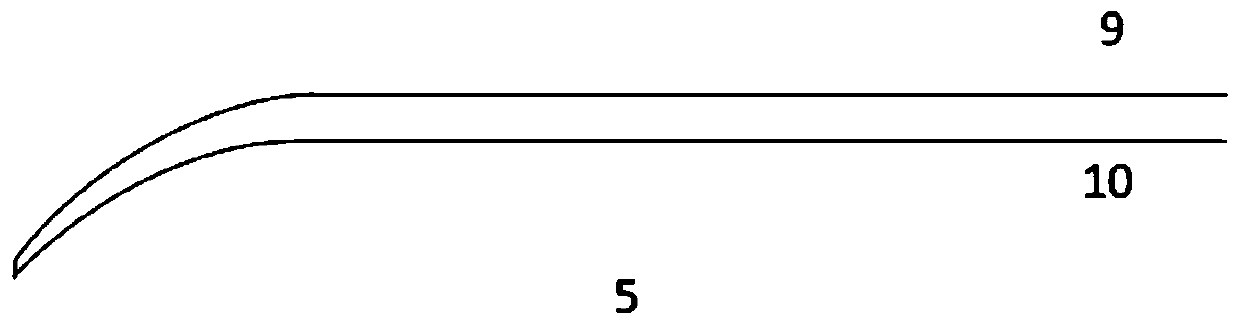

[0030] like figure 1 As shown, the main structures required by the double-layer synchronous measurement method for the curved translucent screen provided by the present invention include a camera 1, a laser device 2, and a displacement stage 3. By this method, it is possible to detect such as figure 2 Relevant information such as holes 6, 7 and screen thickness 8 on the screen 4 of the mobile phone. Detection principle such as figure 1 As shown, first, the laser 2 emits structured light to illuminate the screen of the mobile phone, and then the reflected light is collected by the camera 1 to obtain an image 5 . The image of the upper and lower surfaces of the mobile phone screen is as follows image 3 As shown, the upper light bar represents the upper surface 9 of the transparent part, and the lower light bar represents the lower surface 10 of the transparent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com