A Method of Ultrasonic Imaging to Detect Part Edge

A technology of ultrasonic imaging detection and parts, which is applied in the processing of detection response signals, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as difficult size evaluation and achieve physical measurement Method Accurate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments:

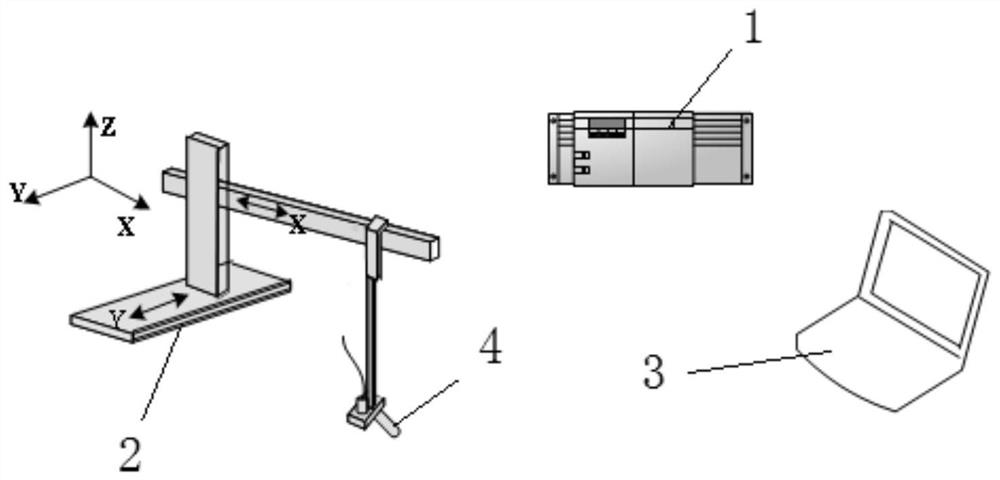

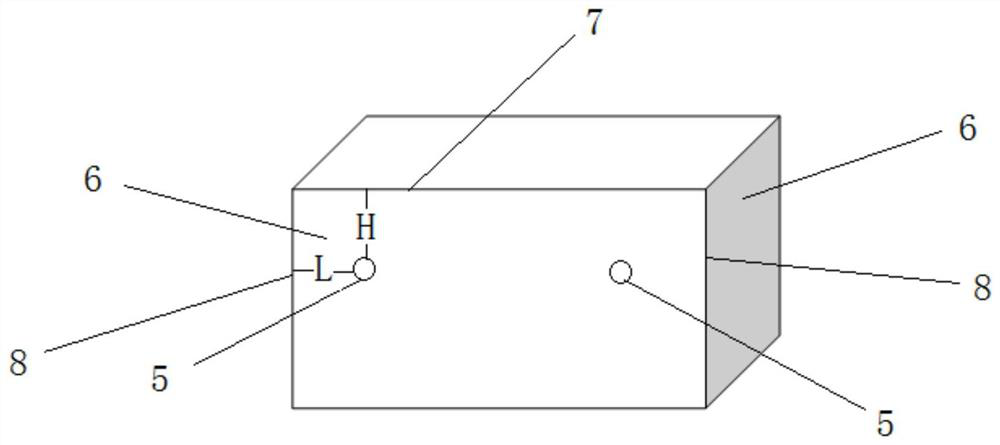

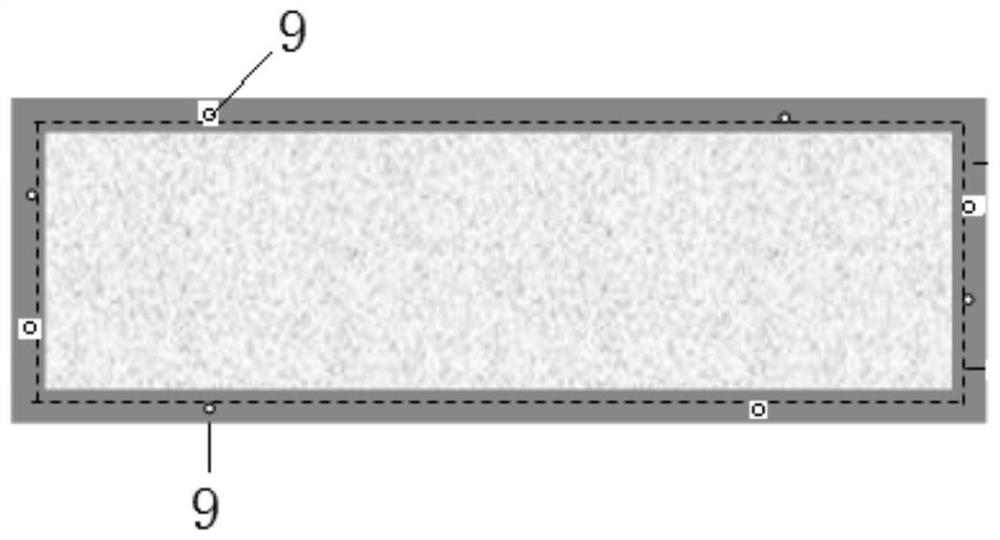

[0029] see attached Figures 1 to 3 As shown, in this embodiment, a superalloy test block with a size of 100mm × 50mm × 50mm is selected to detect, the ultrasonic testing instrument 1 is USIP 40, the mechanical scanning system 2 is SM-J6B-100, and the inspection result imaging system 3 is a Computer, ultrasonic testing probe 4 is a 10MHz focusing probe, steel metal ball 5 has a diameter of 0.5mm, and the probe detects a water distance of 40mm. The metal ball 5 is bonded to the four side walls 6 of the detected part, and the bonding The distance L from the horizontal position to the edge (8) is 30mm, the width of the defect detection signal gate is 5-30mm, and the sticking depth of the ball is 5mm below the upper surface. The detection sensitivity is to adjust the Φ0.8mm flat bottom hole within the depth range of 5-30mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com