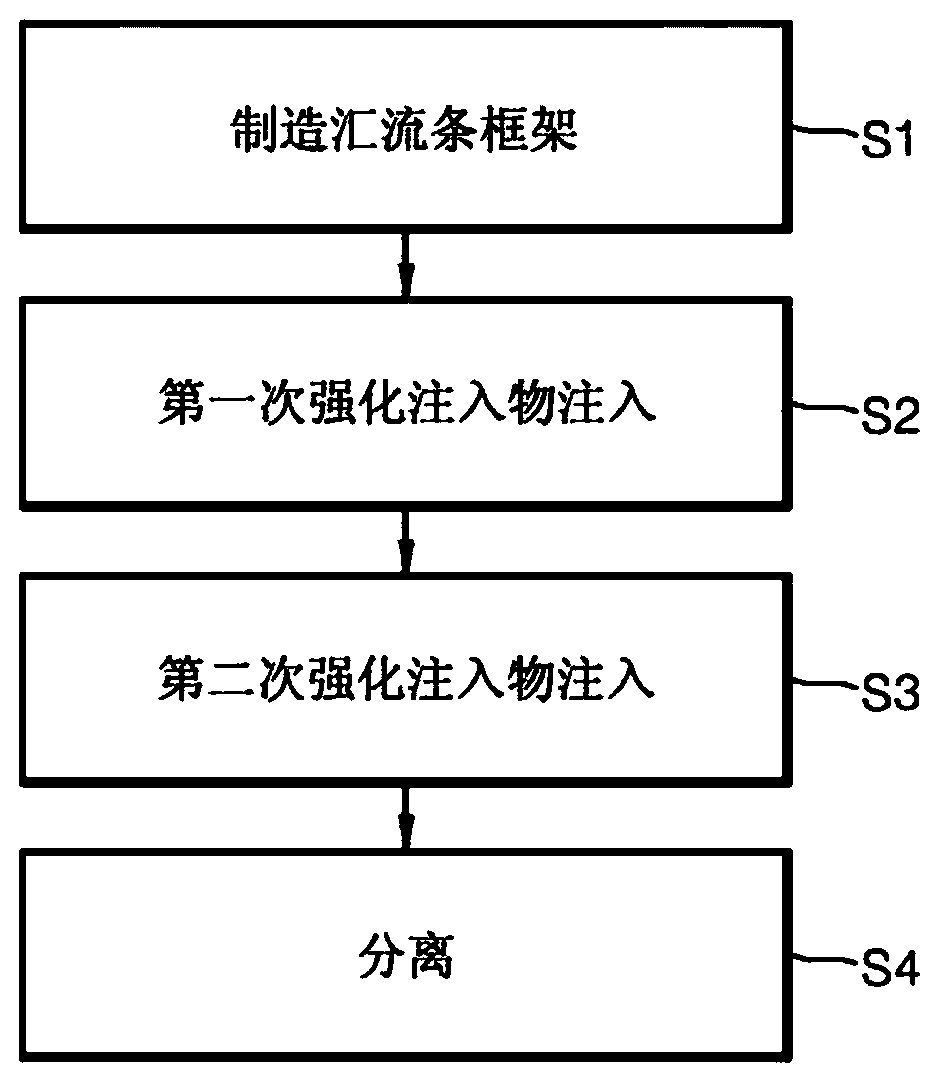

Bus bar manufacturing method and bus bar manufactured thereby

A manufacturing method and bus bar technology, which is applied in the direction of cable/conductor manufacturing, conductive core parts, metal/alloy conductors, etc., can solve the problems of short circuit in the sensing part and the main part, and achieve the prevention of short circuit and ensure the tensile strength , The effect of preventing the decline in price competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

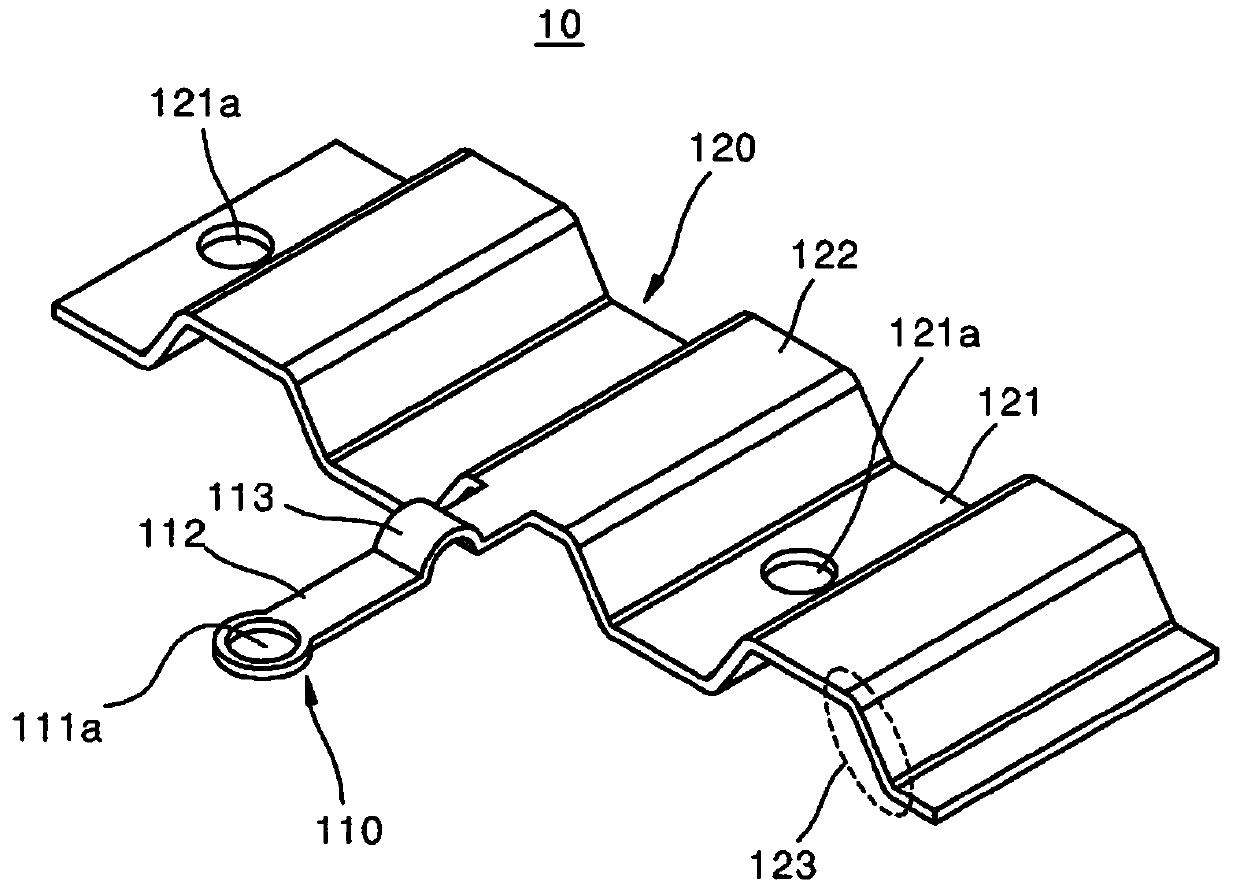

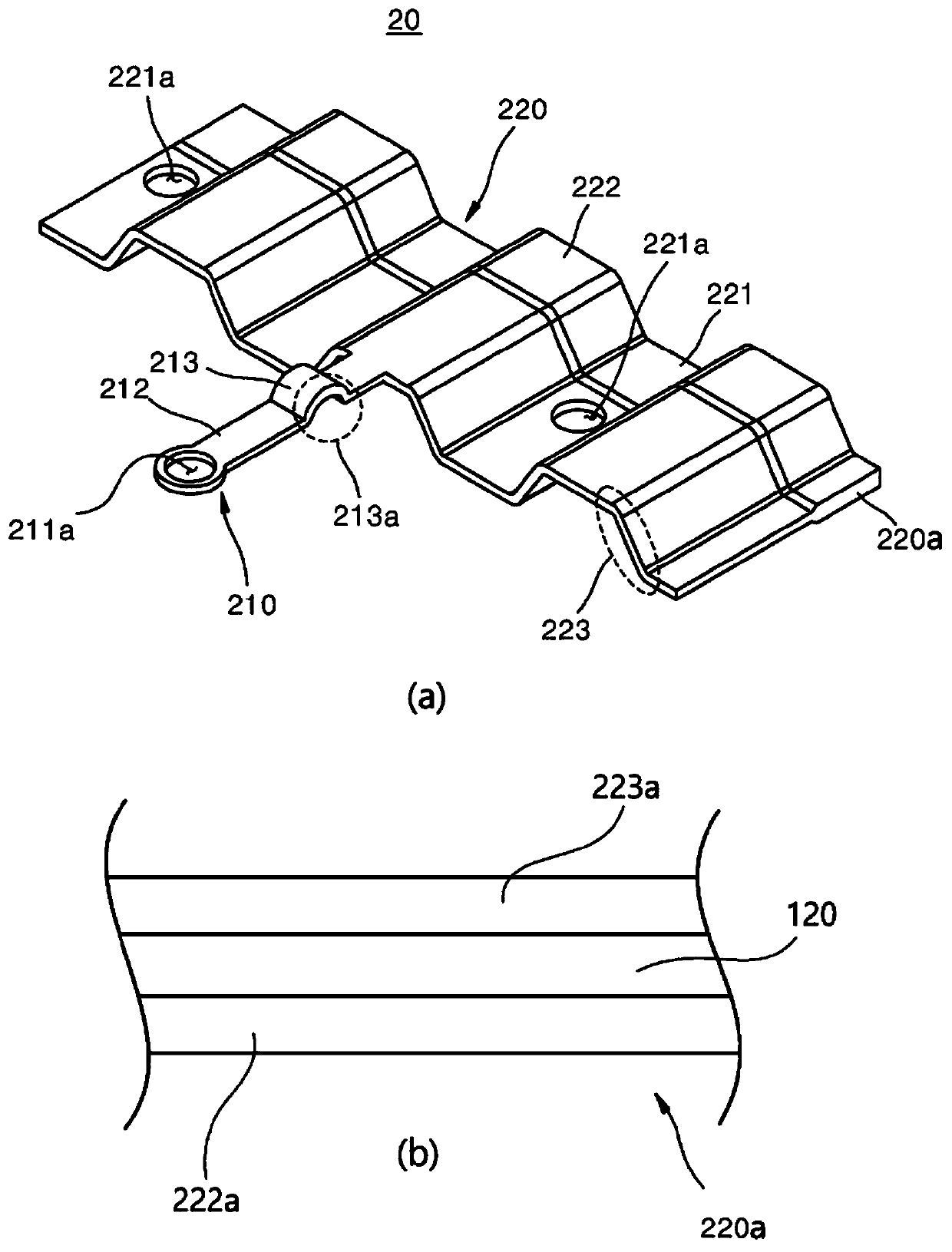

[0083] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, this is only an example, and the present invention is not limited thereto.

[0084] In describing the present invention, when it is judged that specific descriptions for known technologies related to the present invention may unnecessarily obscure the gist of the present invention, detailed descriptions thereof will be omitted. In addition, terms described later are terms defined in consideration of functions in the present invention, and may vary depending on intentions of users or operators, custom, or the like. Therefore, its definition should be defined based on the content of the entire specification.

[0085] The technical idea of the present invention is determined by the scope of the claims, and the following examples are only a means to effectively explain the technical idea of the present invention to those skilled in the art.

[0086] Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com