Automatic forming machine for garbage can body

An automatic forming machine, forming machine technology, applied to other manufacturing equipment/tools, other household appliances, household appliances, etc., to achieve the effect of high work efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

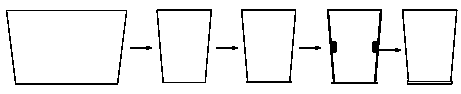

[0021] Reference attached figure 1 As shown, in the trash can forming flow chart provided by the applicant, the iron plate is first bent and welded to form a cylindrical structure, and then the bottom edge is bent backward to form a rolled edge. Inside the semi-finished trash can with a cylindrical structure Weld the reinforcing ribs. After the welding is completed, combine the bottom plate and the rolling edge to form the bottom wall of the trash can. Finally, the upper cover of the trash can is manually welded. The overall shape of the trash can is completed, and finally the spraying process can be realized.

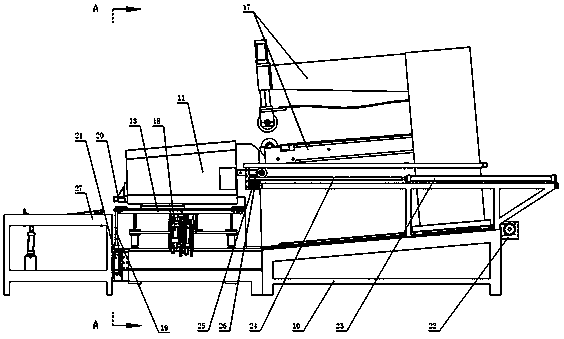

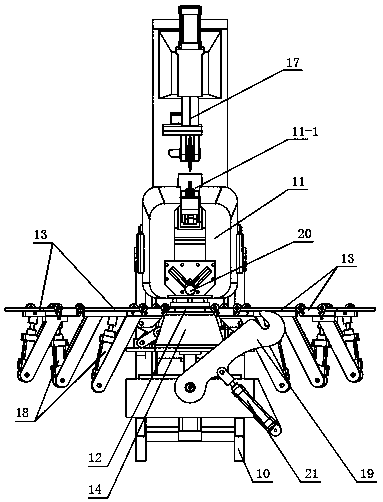

[0022] refer to figure 2 , image 3 As shown, the present invention provides an embodiment of an automatic trash can body forming machine for the above-mentioned iron plate folding and welding process, which includes a forming frame 10 connected with a mouth facing The barrel mold 11 in the front-rear direction is also connected to the bottom pressing plate 12 posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com