Automatic pressing assembling device for middle bearings and anti-rotation pins in automobile air conditioner compressor

A technology in automotive air conditioners and compressors, which is applied in the field of automatic press-fitting equipment for bearings and anti-rotation pins in automotive air-conditioning compressors, and can solve the problem of inability to synchronously feed back the anti-rotation pin pressing force separately, difficulty in meeting production efficiency and precision requirements, Problems such as the inability to complete a large number of press-fits at the same time achieve the effects of cycle reduction, compact and compact design, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with example and accompanying drawing, the present invention will be further described.

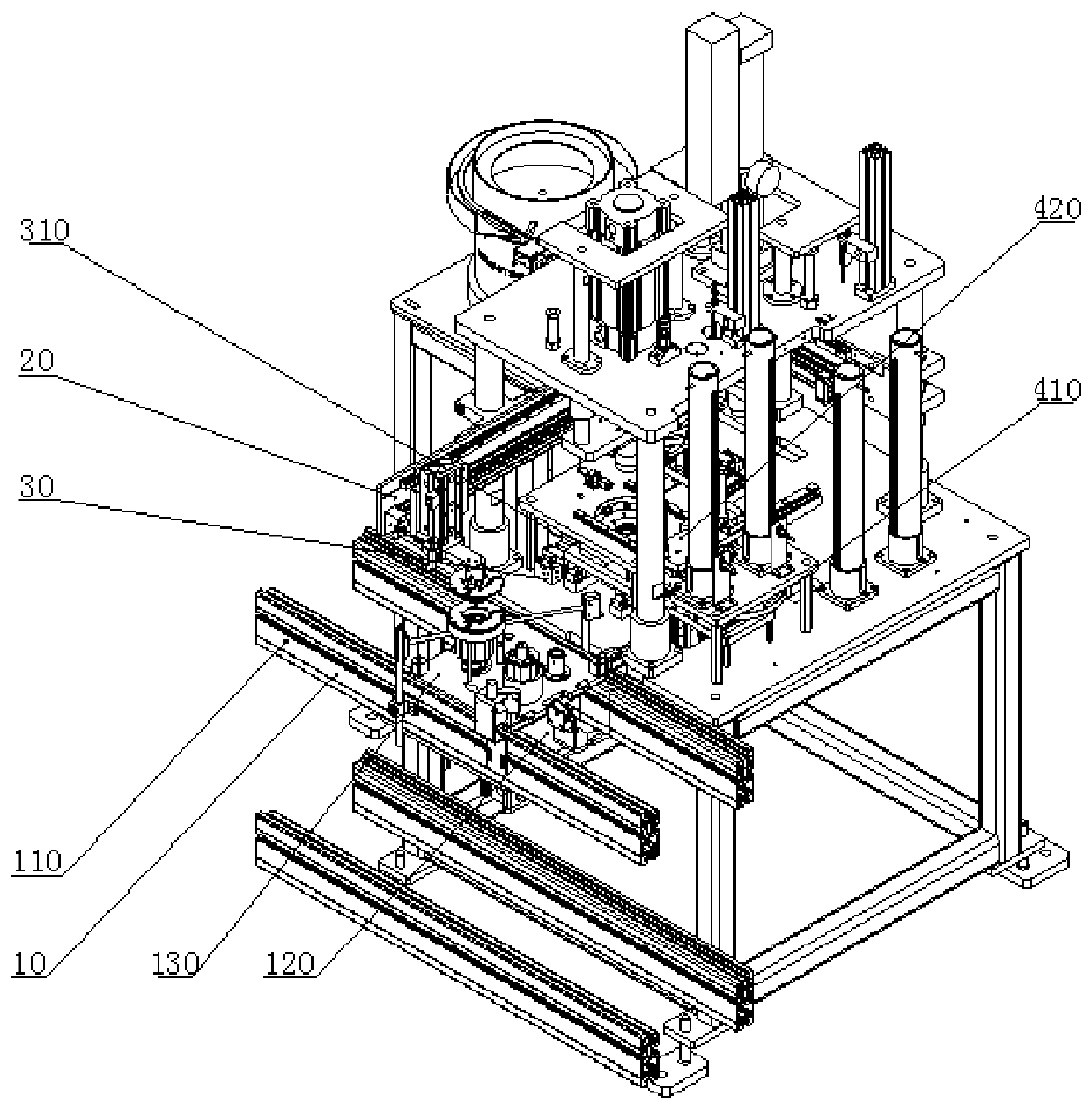

[0039] like figure 1 and figure 2 As shown, an automatic press-fitting device for bearings and anti-rotation pins in an automobile air-conditioning compressor, including a line body mechanism 10, a middle bearing seat transfer mechanism 20, a main tooling transfer mechanism 30, a main tooling mechanism 310, and a bearing material distributing mechanism 410, bearing transfer mechanism 420, anti-rotation pin automatic feeding mechanism 50, anti-rotation pin indexing mechanism 60, anti-rotation pin transfer mechanism 70, anti-rotation pin retrieving mechanism 710, press-fitting mechanism 80, middle bearing press-fitting Mechanism 810, anti-rotation pin pressing machine 820, frame mechanism 90.

[0040] like Figure 20 As shown, the middle bearing assembly 100 includes a middle bearing seat 1001, a middle bearing 1002, and an anti-rotation pin 1003; the end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com