Multi-nozzle 3D printing machine

A 3D printer, multi-nozzle technology, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve problems such as limit weight increase, complex nozzle structure, and troublesome work to support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the multi-nozzle 3D printer and the multi-nozzle parallel printing method of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical idea claimed in the present invention more clearly.

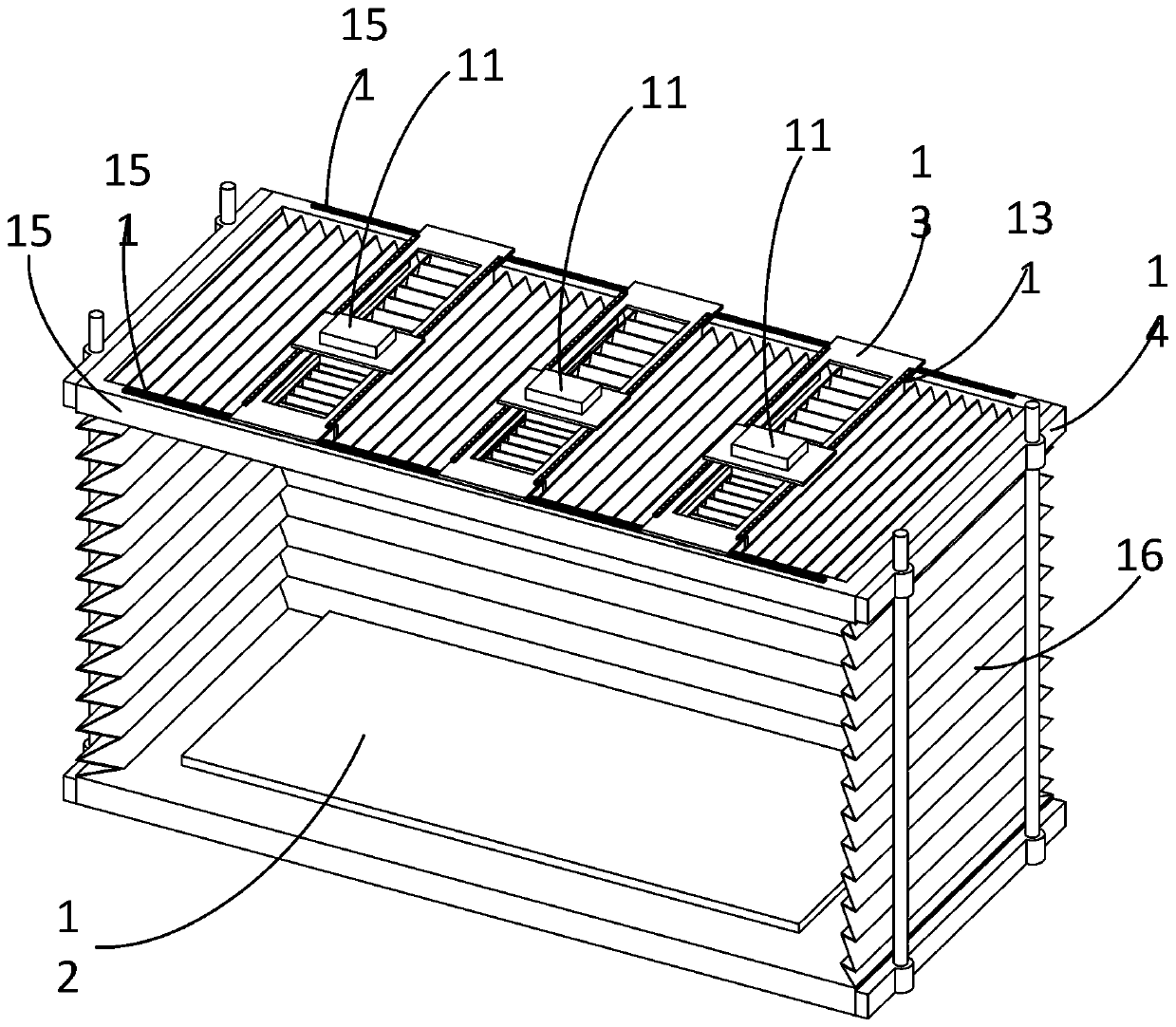

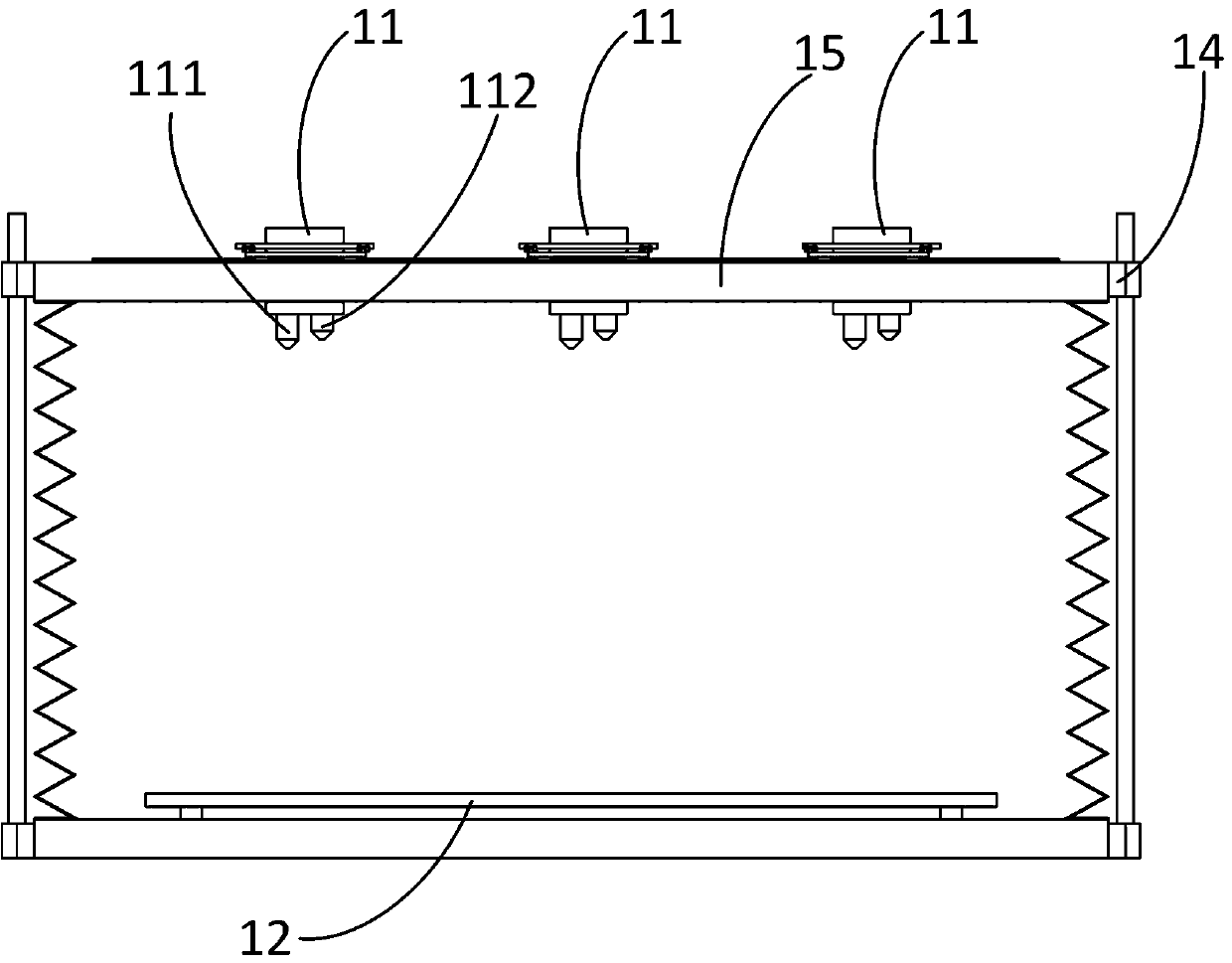

[0020] Such as Figure 1-2 The shown multi-nozzle 3D printer includes 3 nozzle assemblies 11 , and the 3 nozzle assemblies 11 are used to realize parallel printing on the printing platform 12 . The nozzle assembly 11 includes two independent nozzles, namely a model nozzle 111 and a support nozzle 112 . The two nozzles are used to print model materials and support materials respectively. The two nozzles can be switched from high to low through the switching structure in the nozzle assembly 11. When printing, adjust the nozzle height of the working nozzle to a height about 2mm lower than the nozzle height of the non-working nozzle , to prevent non-working nozzles from scrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com