Granular soil prepared from ferronickel slag

A technology of ferronickel slag and particles, which is applied in the field of planting substrates, can solve the problems of low utilization rate of ferronickel slag, and achieve the effects of good plant growth, good water absorption effect, good water retention, fertilizer retention and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

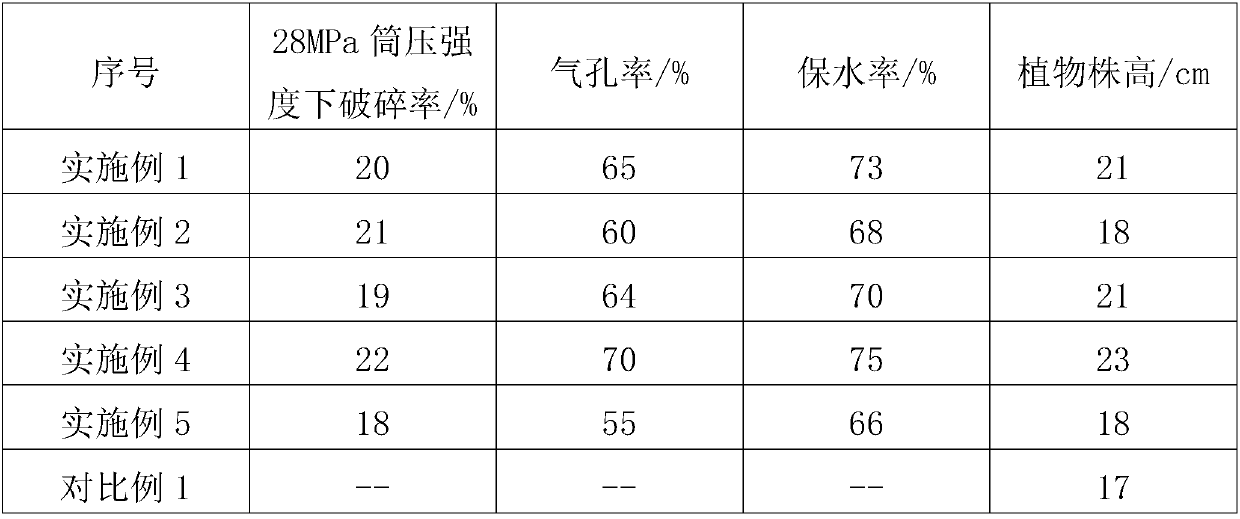

Examples

Embodiment 1

[0030] A granular soil prepared from ferronickel slag, prepared from the following raw materials in parts by weight: 100 parts of fine ferronickel slag powder, 20 parts of coal powder, 10 parts of bentonite, 1 part of titanium yellow material, polycarboxylate 1.5 parts of water reducing agent, 10 parts of 1wt% phosphoric acid solution.

[0031] The granular soil in this example was prepared by the following steps:

[0032] (1) Put the ferronickel slag into a ball mill, add water and wet mill it for 12 hours, then dry it at 150°C, and take the ferronickel slag fine powder below 75 μm after sieving for use;

[0033] (2) Take ferronickel slag fine powder, coal powder, bentonite, titanium yellow material, polycarboxylate water reducing agent by weighing according to raw material ratio, put into mixer and mix evenly to obtain mixture;

[0034] (3) Pour the mixture obtained in step (2) into a ceramic sand high-speed granulator, then weigh 1wt% phosphoric acid solution according to ...

Embodiment 2

[0039] A granular soil prepared from ferronickel slag, prepared from the following raw materials in parts by weight: 100 parts of fine ferronickel slag powder, 15 parts of straw powder, 5 parts of calcined kaolin, 0.2 parts of naphthalene-based water reducer, 1 wt% 15 parts of phosphoric acid solution.

[0040] The granular soil in this example was prepared by the following steps:

[0041] (1) Put the ferronickel slag into a ball mill, add water and wet mill it for 12 hours, then dry it at 300°C, and take the ferronickel slag fine powder below 75 μm after sieving for use;

[0042] (2) Weigh ferronickel slag fine powder, straw powder, calcined kaolin, and naphthalene-based water reducer according to the ratio of raw materials, put them into a mixer and mix them evenly to obtain a mixture;

[0043] (3) Pour the mixture obtained in step (2) into a ceramic sand high-speed granulator, then weigh 1wt% phosphoric acid solution according to the ratio of raw materials and pour it into...

Embodiment 3

[0048] A kind of granular soil prepared by using nickel-iron slag, prepared from the following raw materials in parts by weight: 100 parts of nickel-iron slag fine powder, 25 parts of starch, 20 parts of ball soil, 1.5 parts of fatty acid-based water reducer, 1 wt% of Phosphoric acid solution 20 parts.

[0049] The granular soil in this example was prepared by the following steps:

[0050](1) Put the ferronickel slag into a ball mill, add water and wet mill it for 12 hours, then dry it at 300°C, and take the ferronickel slag fine powder below 75 μm after sieving for use;

[0051] (2) Take ferronickel slag fine powder, starch, ball soil, fatty acid water reducing agent by weighing according to raw material proportioning, put into mixer and mix evenly to obtain compound;

[0052] (3) Pour the mixture obtained in step (2) into a ceramic sand high-speed granulator, then weigh 1wt% phosphoric acid solution according to the ratio of raw materials and pour it into the granulator, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com