Leakage detection method for gas supply system of natural gas engine

A leak detection and air supply system technology, which is applied in engine components, engine control, combustion engines, etc., can solve the problems of not ensuring the safety of the air supply system, having a large impact, and not being enough to form an alarm signal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention. In the following detailed description, certain exemplary embodiments of the invention are described by way of illustration only. Needless to say, those skilled in the art would realize that the described embodiments can be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims.

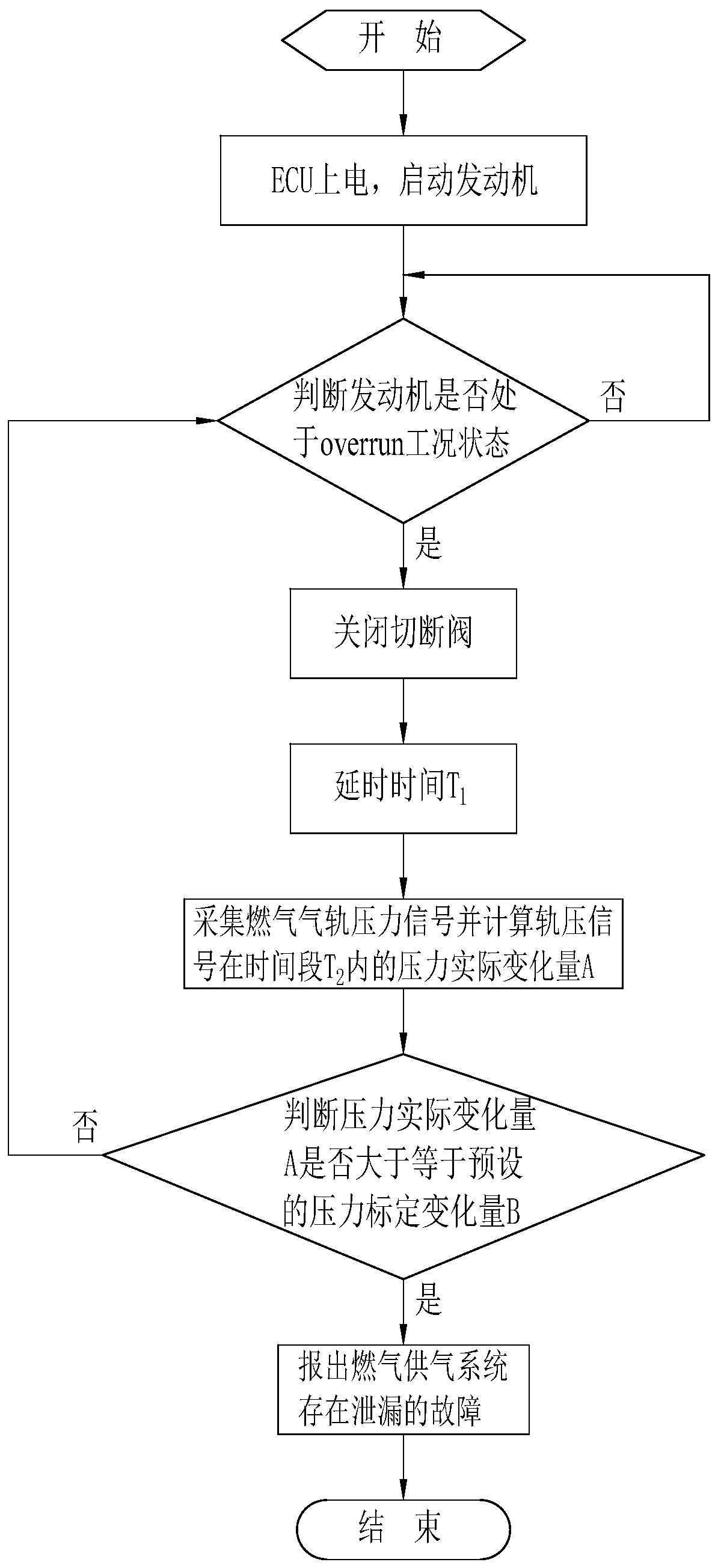

[0024] Such as figure 1 As shown, a leak detection method of a gas supply system for a natural gas engine is completed under the cooperation of the cut-off valve, the injection valve of the gas supply system of the engine, and the electronic control unit ECU on the engine, including the following steps,

[0025] Step 1, the electric control unit ECU is powered on, and the engine is started.

[0026] The electronic cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap