An inner support multi-stage electric cylinder

A technology of electric cylinders and cylinder barrels, which is applied in the direction of electric components, transmission devices, electromechanical devices, etc., can solve the problems of low power density and low transmission efficiency of trapezoidal screw, and achieve the goal of increasing power density, improving efficiency and reducing transmission links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

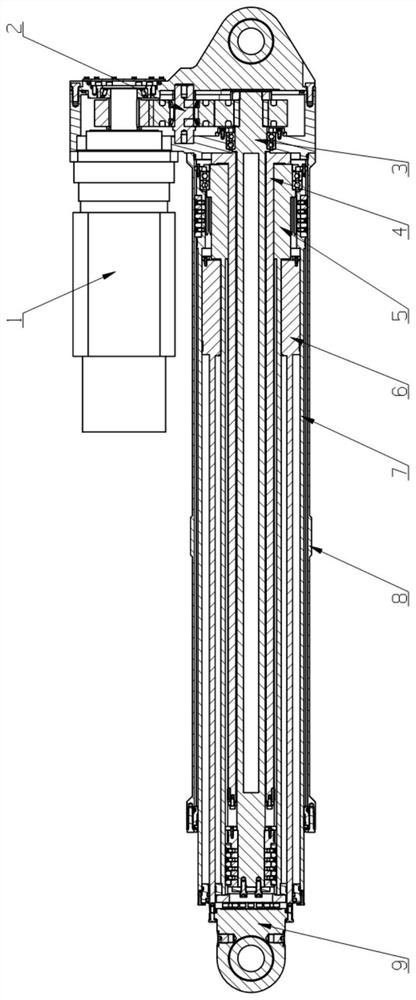

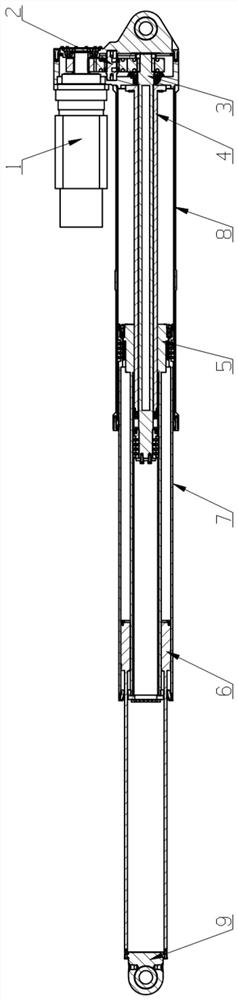

[0022] like figure 1 , figure 2 As shown, an internally supported two-stage electric cylinder provided by an embodiment of the present invention includes a power unit 1, a gear box 2, a torsion bar 3, a fixed screw 4, a sliding screw 5, a second-stage push rod 6, and a first-stage push rod. Rod 7, cylinder barrel 8 and push rod head 9.

[0023] Among them, the power unit 1 is connected to the flange of the gearbox 2; inside the gearbox 2 is a parallel gear transmission, which is used to transmit the output torque of the power unit 1 to the torsion bar 3; the torsion bar 3 is used to pass the obtained output torque through The guide key at its end is transmitted to the sliding screw 5, so as to realize the rotary mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com