Tensioning platform and thin film optical surface tensioning platform combination device

A technology of thin-film optics and locking devices, applied in the field of precision optics, can solve the problems of reduced adjustment accuracy, complex structure, and many transmission links, and achieve the effects of reducing system transmission errors, simplifying the overall structure, and fewer transmission links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

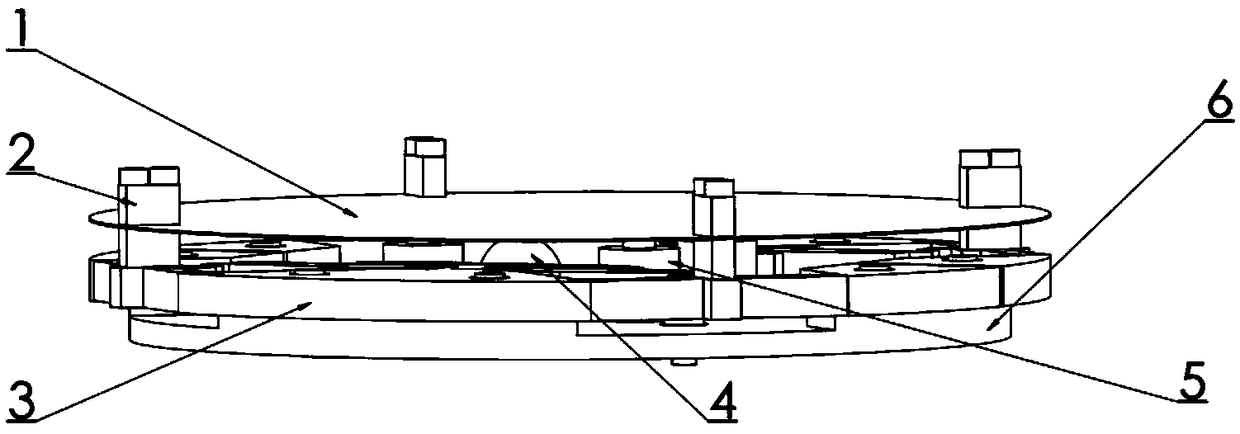

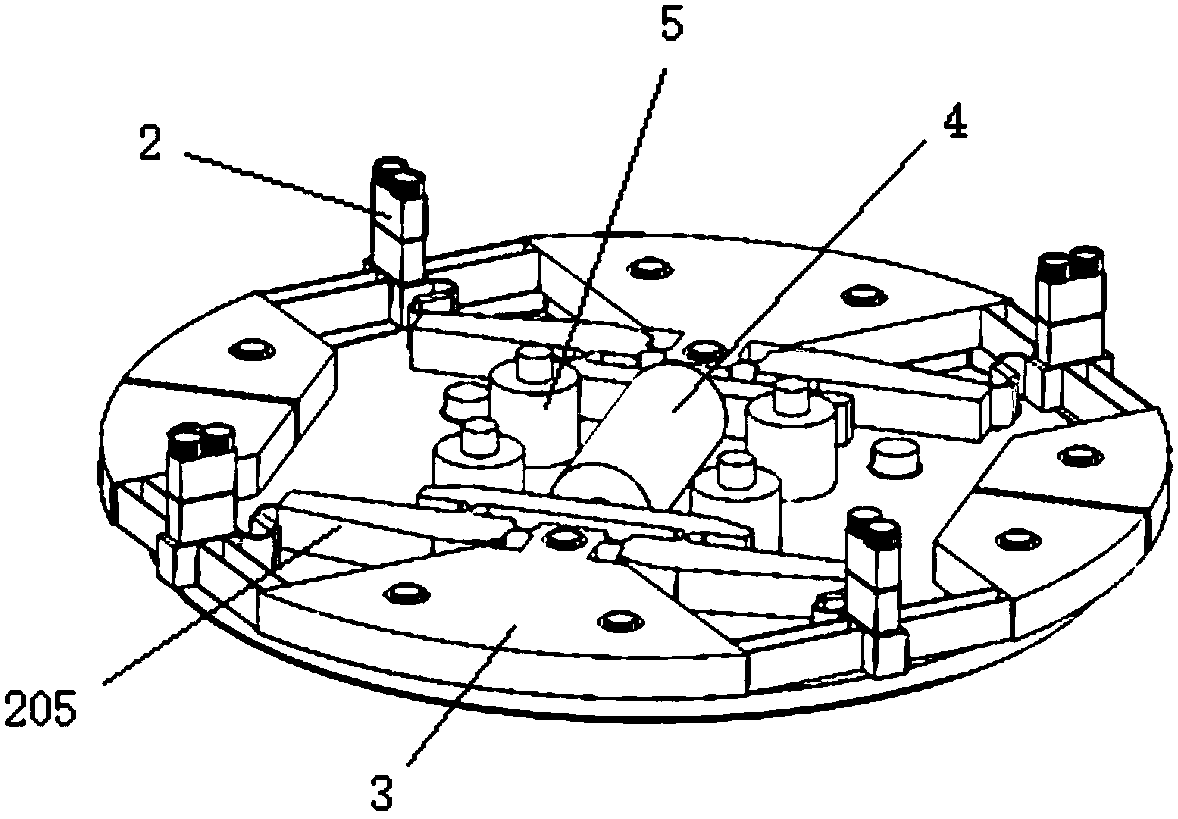

[0054] Such as figure 1 As shown, the film optical surface tensioning platform combination device provided by the present invention includes: film optical surface 1, four pairs of eight clamping blocks 2, a flexible tensioning mechanism 3, a bidirectional displacement driver 4, four Clamp locking device 5 and a supporting mounting base 6 .

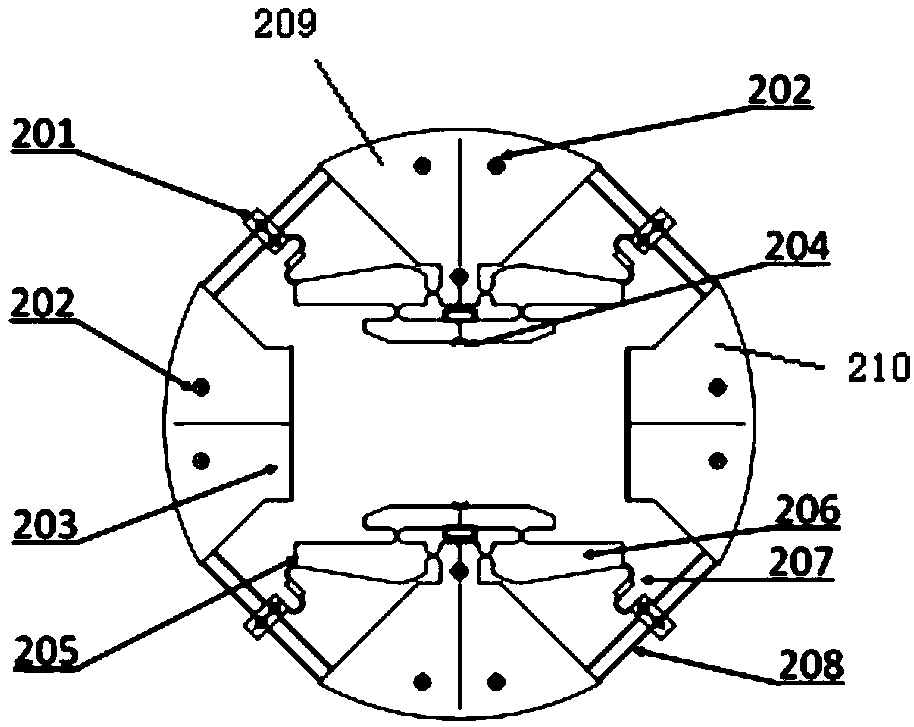

[0055] Specifically, the film optical surface 1 is fixed on the four symmetrical output blocks 201 of the flexible tension mechanism 3 through eight clamping blocks 2; The driver 4 is installed on the input end of the flexible tension mechanism 3 through the adjusting bolt 204; the four clamping and locking devices 5 are also distributed on the circumference close to the center of the shape surface, and are fixed on the support installation base 6 by bolts, and the follower rod The output end of 401 is bonded on the optical surface 1 of the film. When the two-way displacement driver 4 is connected with a current or voltage signal, both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com