Flow adjusting plate for ultra-large-diameter all-welded ball valve

An all-welded ball valve and super-large caliber technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of not being able to meet the needs of modern industrial production and increasing project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

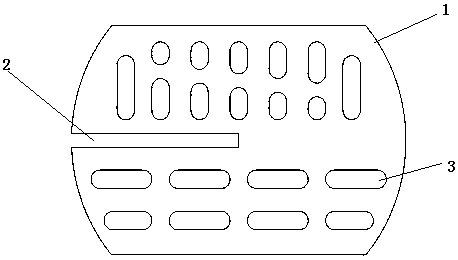

[0015] Example: such as figure 1 As shown in the figure, a diverter plate used for a super-large caliber all-welded ball valve includes a diverter body 1 made of metal materials. Groove 2, the length of groove 2 is equal to half of the length of the flow regulating plate body 1, and flow regulating holes 3 are evenly distributed on the flow regulating plate, and the flow regulating plate body 1 is divided into upper and lower parts symmetrically by the groove 2, and the flow regulation The upper part of the plate body 1 is provided with 12 regulating holes 3 , and the lower part of the regulating plate body 1 is provided with 8 regulating holes 3 .

[0016] In this embodiment, the shape of the 12 regulating holes 3 provided on the upper part of the regulating plate body 1 is elliptical, and the two regulating holes 3 have the largest area respectively arranged on both sides of the regulating plate body 1, The other 10 flow regulating holes 3 are divided into two groups and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com